Ball Premier Lab Wins Medal Of Excellence Award For Its Advancements In Seed

Not every company has the ability to say that it has set quality standards in an industry, and in doing so, changed the way product is brought to market. But Ball Premier Lab can.

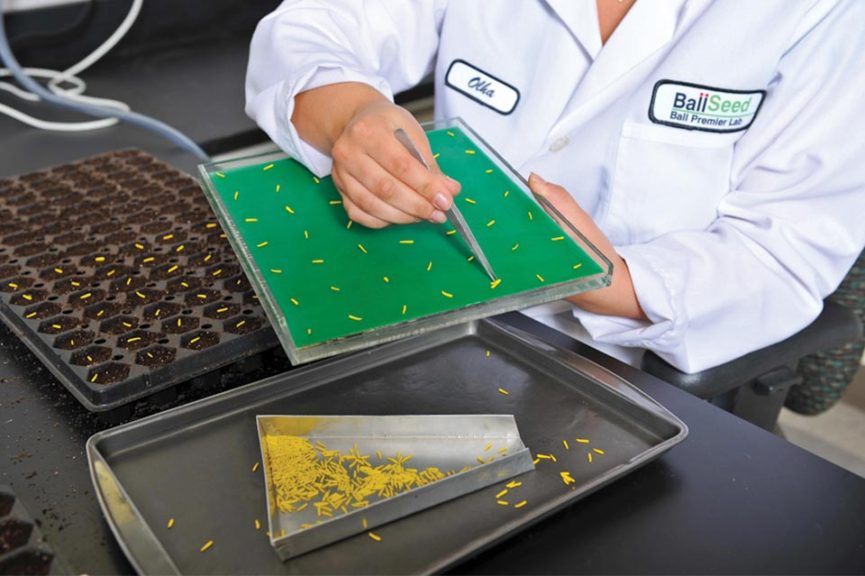

The seed laboratory division of Ball Horticultural Co. has revolutionized the seed industry with the development of its advanced testing and technology over the past 30 years since it was founded. From Ball’s original high-energy seed forms to the development of seed testing protocols that have eliminated dead lots for growers, to the Ball Vigor Index that has shown a direct correlation between germination stand, vigor, and useable count, and superior seed coating and pelleting techniques, the lab has set a high standard for providing premium seed in the industry.

With these improvements in seed technology, in addition to advanced breeding techniques, growers are able to rely on seed inputs that help increase their margins, lend themselves to automated technology, and reduce shipping and storage issues. For all of these reasons, Greenhouse Grower honors the Ball Premier Lab’s accomplishments, with its 2016 Medal Of Excellence for Industry Achievement.

[blackoutgallery id=”131748″]

Built From Humble Beginnings

The Ball Premier Lab was established around 1983 in a single-wide mobile office trailer in West Chicago. Its second employee, Teresa Johnson, is now the Lab Manager, following the recent retirement of Mary Ann Berg, who managed the lab for 18 years.

While space and technology was limited in that first trailer, the technologies that emerged include Ball’s High-Energy Seed, a refined seed technology that delivers improved germination and uniformity, Genesis Seed (or primed seed, which germinates under a wider range of temperatures and delivers better uniformity), and film-coated seed, which ensures better flowability through seeders.

When the lab started to get into seed pelleting, more room was needed, so in 1990, the seed lab renovated one of the original warehouses on the Ball campus, which was used in the early days as a trackhouse, and moved in there.

Pelleted seed technology — and the products it produced — continued to evolve and with more demand from the facility, Ball Horticultural Co. decided to construct a new, LEED-certified expansion to house the growing lab. In 2011, the Ball Premier Seed Lab moved into the new facilities, which measures 18,000 square feet, plus another 9,000 square feet for storage.

Ball Advances Seed With Technology

The new facility provides pellet, coat, prime, and test seed germination services not only for Ball properties including PanAmerican Seed, but also for Ball Seed and contract customers. Today, more than 80% of Ball Seed inventory — billions of seeds each year — pass through the Ball Premier Lab.

Products that have evolved from the lab recently include treated seed, Ball Controlled Growth seed, multi-seed pellets, and Fuseables precision multi-pellets. Even the Fuseables have changed from jagged edge to rounded to bullet-like formulations. All products are developed to work smoothly with drum seeders and any other automated advancements that come along.

“We probably do more of this kind of work than the rest of the industry combined,” says Steve Cull, Director of Seed Processing and Operations.

The Ball Vigor Index is another product of the Ball Premier Lab that has set a standard for seed quality throughout the industry. The index, introduced in 1993, is a patented plug testing method that determines the vigor and uniformity of seed lots. Lots that don’t pass are rejected.

“Prior to the Ball Vigor Index, the breeder producers would decide if the product was sellable, and they would send it to distribution companies to ship. But growers told us quality was low,” says Robert Conrad, Seed Technology Research Manager. “The Ball Vigor Index judges everyone’s product in a uniform way, and sets the bar for all breeder producers to have the quality level that they try to achieve.”

The development of the Ball Vigor Index is an example of how the lab has worked with customers to develop solutions.

“It’s important to us to advance seed technology so our customers will succed and be more profitable,” says Robert Conrad. “The lab is entirely industry focused. We are attentive to customer needs and try to see if we can apply some technology to help solve their problems.”

Cull says over the years, Conrad has been instrumental in the lab as it has incorporated a range of technology, from the seed analysis used in Ball Vigor Index testing to the high-tech seed coating process. The team develops and engineers the ideas, and then out-sources to local manufacturers to custom build the equipment. More advancements are forthcoming, like the recent Ball Coleman Seed Counter, which is quickly becoming a standard throughout the agriculture industry.

“I believe that the Ball Premier Lab is the best in the world,” says Randy Tagawa, Owner of Tagawa Greenhouses in Brighton, CO. “Ball took state-of-the-art technology and a team of phenomenal people who are striving for excellence. It is amazing to see what they are doing to provide consistent, high quality products that make growers successful.”