More Fuels For The Fire

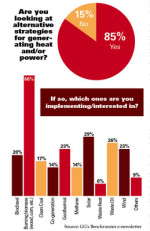

Over the past year of coverage, we’ve tried to highlight all the different ways you can keep from burning up fuel, and therefore money, wastefully. From growing cooler to buying larger plugs to fuel purchasing strategies to production zoning and maintenance scheduling, each of our 14 articles confronted a single issue head-on, hopefully giving you something to take away and use in your business. As the survey results from our Benchrunner e-newsletter (available at www.greenhousegrower.com/benchrunner) show, fluctuating fossil fuel prices have many growers looking elsewhere to fulfill their heating needs. For this final installment, we’ve taken this most talked-about and fastest-developing part of the greenhouse business — alternative energy —and provided an overview that may spark one final energy-saving idea for your operation.

Close Your Greenhouse

The talk at the prestigious Horti Fair Innovation Awards last year was all about the “closed greenhouse” concept. This year, the talk focused instead on “semi-closed” greenhouses, a less ambitious but more realistic goal. There are six to eight semi-closed concepts under development in Holland, and installations are taking place currently in both Canada and California. One of these concepts, the Aircokas, involves using misting equipment during high sunlight hours to cool the greenhouse. Along with vertical fans designed to create even temperature distribution, this system can save more than 30 percent in fossil fuel consumption. Another concept showcased by Priva at the Horti Fair show uses perforated tubes under greenhouse benches to achieve the same vertical standardization of air mass temperature.

However, no matter what happens inside the greenhouse proper, the backbone of this type of system involves the storage of solar energy in hot and cold water in aquifers under the greenhouse in geothermal wells drilled deep enough underground to be unaffected by seasonal temperatures. These aquifers are large. The ratio suggested at research presentations in Holland recently was 4:1 for aquifer to greenhouse area, so the storage area you need may extend beyond your property. Government regulations are an obvious factor here, as are practical considerations (such as proximity to town wells, groundwater movement, etc.). Finally, consider that this is developing technology, and it may be years before it is perfected. Regardless, the potential for savings with any of these closed systems make aquifer heat storage worth investigating. Contact your Extension agent and/or controls company for more information on your area’s potential.

Learning Curve

Our online coverage of this year’s Horti Fair (available at www.greenhousegrower.com/hortifair) detailed how Litchfield, Mich.-based Raker Inc. recently installed a wind testing device in order to study the possibility of using a wind turbine to power its electrical system. According to Raker’s maintenance manager Robert Mitchell, “When the winter months come around, our light bills get ugly, so we’re trying to find a better solution than to keep paying the gas man.”

As far as alternative sources go, many growers have already jumped on the alternative fuel-powered train. Over the course of this past year, we’ve covered any number of them (both in print and online), from the pelletized coal burner at Ohio-based Cedar Lane Farms, to the waste wood boilers at Arkansas-based Parks Brothers, to the landfill methane gas boiler at Indiana’s Crossroads Greenhouse, to the biomass boilers at Michigan-based Walters Gardens and Dickerson’s Greenhouses. All are reporting successful experiments so far and don’t see the verdict changing anytime soon.

Alec Mackenzie of Argus Controls, while enthusiastic about the potential for alternative fuels, has some cautionary tales for growers looking to disconnect from the natural gas pipeline.

“Alternative energy systems are well worth considering, but they must be properly engineered and integrated with the rest of your operation,” he says. “The money saved by these systems usually more than justifies this level of commitment, but there is no point starting a project if you are not completely committed to seeing it through.” In other words, growers must commit to a learning curve for the ongoing maintenance and operational management required by a new fuel source. For instance, the electric boiler at Metrolina Greenhouses took months to integrate into the system, but according to maintenance manager Cor Zethof, “Now it’s running like a little baby,” and pumping out 2,200 gal./min. of hot water at an off-peak electrical price of a few cents.

Mackenzie points out that most greenhouse operations will find 80 to 90 percent or more of their total annual energy bill will be burned in the first 50 percent of total heating capacity and only 10 to 20 percent burned in the remaining 50 percent. Therefore, it makes sense to invest in an economically superior alternative fuel boiler in order to transfer that first 50 percent while still using a pre-existing gas- or oil-fired heating equipment as a backup. Fuel costs for this additional heating equipment will be high, but only when they are running, and as an added bonus. Growers following this framework will also have some great on-line redundancy should something go wrong with the primary, alternative-fueled boiler.

Growers looking to invest in such equipment should consider investing in the full system, including a hot water storage tank (also known as a heat buffer or decoupling system). These store excess heat to assist with future peak heat demand, thereby allowing the user to purchase a smaller, less expensive alternative fuel system and still satisfy most, if not all, greenhouse demands by running it continuously at optimal firing rates, 24 hours a day.

Keep It Clean

Finally, Mackenzie says, there are some common-sense steps that interested growers should take, including:

-

Optimizing boiler operation to suit the fuel being burned, not the greenhouse demand. Most alternate fuels (coal, biomass, etc.) don’t respond well to the rapid demand fluctuations of a greenhouse.

- Decoupling the heat producer (boiler) from the load (greenhouse) by using heat storage or heat buffers, or by only running base load on the alternate fuel while using a fast responding heat source (usually natural gas) to support the fluctuating demand.

-

Make sure you have very stable, long-term fuel sources under contract, or at least several competitive fuel sources readily available before you commit to a major capital investment.

-

Pay particular attention to the quality of the alternate fuel to ensure it stays close to optimal specifications. You don’t need wildly varying moisture content interfering with efficient, clean combustion. You also don’t need rocks and metal debris in your feed augers!

- Go with clean-burning technology. Your greenhouse will be the first to notice if you are dumping soot and pollution, and your neighbors (not to mention the Feds) won’t be too far behind!