The Loading And Unloading Problem

What is more expensive — hiring a truck to drive 1,000 miles with one plant on it or 2,000 plants? Well, for those who are not mathematically inclined, the cost of the transport divided up among 2,000 plants is much less than one plant. Not rocket science — right?

So why is there such a debate with regard to how you ship your product, how you load it and how you get it off the truck when you deliver it? This is an easy answer if you have your own truck. Fred, the driver, loaded it, drove to the customer and unloaded it. He then drives back to you, empty (see last month’s column).

However, when using common carrier, you have many choices of loading and unloading. Some good, some bad. Some are more costly than others and some have hidden advantages and disadvantages.

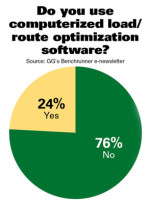

We have seen some interesting ways in which trucks are loaded. One of the most interesting things I have picked up on is how few growers actually optimize their loads using commonly available technology. Computer algorithms (“programs”) can take your entire week’s shipping data and tell you exactly the most efficient way to load and route your trucks. I see every week (no joke) at least one grower reduce his truck needs by 20 percent or more using technology to do this. So for every 100 trucks you thought you needed, you could save 20. Not bad. The computer does it in about 30 seconds and is always right.

Capacity is tight throughout the transportation industry, exacerbated by the seasonal nature and special equipment requirements of live goods. This spells “premium pricing.” Computerized optimization reduces the total number of trucks you need–effectively reducing the total “strain” that your nursery puts on the industry as a whole. The fewer trucks needed overall, the longer it will take for seasonal prices to skyrocket, allowing you to keep more of your hard-earned money in your pocket. By chasing these inefficiencies out of shipping, we all help each other keep rates as reasonable as possible deep into the spike seasons.

Live goods (plants, trees, flowering product, etc.) are unique in the transportation industry. I do not know of any other product that can be loaded in the truck in so many different ways. Here are a few that jump to mind: floor loaded, California stacked, decked, shelved, boxed, hanging, racked (with several rack sizes), on rollers–you get the idea. Most for-hire carriers will give you three things–a truck, a trailer and a driver. Anything else you need for special loading needs is a bonus.

Obtaining consistent capacity, especially when your equipment requirements are specialized, is almost impossible if you have any real load volume. Common carriers, generally speaking, cannot drag around decking, shelves or provide lift gates and other special equipment “just in case” they pull a plant load. In fact, many of their other shippers, because they want to maximize the trailer capacity (cube it out), refuse to load any trailer unless it is clean and 100 percent empty.

This has pushed growers to do one of several things to accommodate their specific loading equipment needs. First, more drivers are refusing to take floor-loaded or California-stacked loads. Who can blame them? Tailgating and unloading several thousand plants is hardly fun. Growers have come up with solutions that benefit the driver and the customer by shipping on rental racks or using palletized boxes. This keeps quality high (less material rejected and claimed) and the material “display ready” in many cases. If you use rental racks, you pay a flat, one-way rental fee per rack. The rack company (such as EZ Rack — www.ezrack.com) then worries about picking the racks up and getting them to the growers on an as-needed basis.

Many growers have been successful in getting the customer to either pay for the rack fees outright or to get higher prices for the product to offset these costs. The benefit is that a driver/client has an easy time unloading the truck, so you can negotiate lower delivery pay for each stop and you have a wider pool of drivers willing to compete for your loads (driving your costs down). Moreover, plants delivered on racks are virtually ready for sale–so everyone wins.

Boxed material is also becoming more common. We are seeing more growers using “pallet boxes” or “bin boxes.” These are, essentially, boxes perched atop a pallet, then stacked two high. Each customer/delivery may get several pallets, all well marked for the driver and consignee, that could contain one plant or be full to the top. This is akin to an ocean container you see on cargo ships–self contained and ready for delivery. Once again, creative loading techniques help you balance the need to load the truck as fully as possible while making it easy to get capacity to take your loads and keep the client happy with a tidy and simple delivery solution. Remember, your customers would much rather unload six pallets or six racks on a busy spring day rather than have to help unload 600 loose plants.

Moreover, unloading is always an interesting issue with live plants. First, nobody wants to do it. The driver looks at the receiver and the receiver looks at the driver, both hoping the other will give in and unload. I have witnessed several hours go by where nobody wants to unload loose plants, especially in the busy spring season when the receiver should be serving customers and selling plants. If a third-party merchandiser is involved, it gets even more interesting. The merchandiser may not know to be at the store when the truck arrives (a very common occurrence) and simply cannot get to the delivery location to help unload at short notice. Now you have an upset driver, an upset customer and an upset merchandiser.

If you use a third-party merchandiser (such as Retail Plant Services, www.hpsw.net) and a common carrier, we highly recommend you use carriers that provide Internet load tracking capabilities. In addition, a very simple solution (solving 90 percent of your problem calls) is to give the third-party merchandiser the cell number of the driver. Even better, use a third-party merchandising company that has an existing relationship with your transportation source or logistics provider. That way, they can call to get an accurate estimated time of arrival on the truck and be ready to meet the driver to expedite the unloading process. Everyone wins.

My advice to you is simple: Put a little thought into how you load, unload and optimize your loads. I will almost guarantee that if you take this article with you to your next transportation meeting and read it out loud, you will get at least one good idea you can use. Try it. It will save you several thousands of dollars immediately and who knows how much over the long term!