Do I Use My Own Trucks Or A Common Carrier?

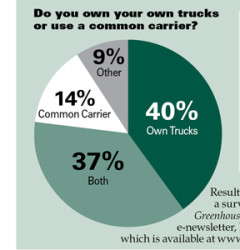

Many growers call me here at Interstate and tell me they have their own trucks and drivers and they only use common carriers for the “occasional load.” They justify this by telling me how common carriers are too expensive, so they bought their own trucks and trailers. My next question to them is always, “What is the cost of your freight as a percent of your shipped goods?” Surprisingly, few growers know or, even worse, they guess.

If you are shipping on your own trucks, you need to know what the true cost is. What is interesting about our business is the seasonal component. Consider this: if you were shipping a consistent amount of freight over 12 months, you would be getting near 100 percent utilization of your equipment. That means your trucks and drivers would be used five days (or more) each week for 12 months of the year.

However, most (perhaps all) growers do not run their equipment anywhere near 100 percent of the time, but for some reason, they insist on having trucks and trailers sitting idle, collecting dust until they are needed again. Because drivers don’t have consistent work, they tend to move on, only to be replaced again when the next seasonal need arises. If you have read this far, you may be saying, “Oh, that’s not me.” You may be justifying the fact that you use your own trucks, yet you supplement your needs with common carriers as needed. This may be a better solution, but not necessarily the best. Why? Simple economics. Maybe you remember Economics 101 and Adam Smith’s division of labor and the economies of scale? For a refresher course, please read on.

Climbing Costs — No End In Sight

The bottom line is this: if you can get the same or better service from a provider that charges the same or less, it makes sense to outsource your transportation. Economically speaking, owning trucks and trailers is almost never going to be a cost-saving proposition. Fuel cost is through the roof and, some say, not coming down to those wonderful “inflation-adjusted 1983” levels. Insurance costs are insane. Drivers are hard (some say impossible) to find. Maintenance is a pain, and costly, too. Oh, and did we mention the lease payments for the equipment (or the cash you used to buy it)?

Anyone can see the inherent costs of owning the equipment and running it is up and it keeps climbing, with no end in sight.

However, the real advantage of outsourcing transportation rather than owning your own trucks is one that not many people consider. Your trucks must return back to your nursery or farm, usually empty or perhaps with a few of your racks. If your truck went 200 miles to its last delivery, the driver must turn around and drive back with nothing to show for it. If you ever do this, you have just doubled your cost of transportation. You are still paying fuel, driver pay, maintenance costs, wear and tear, which is draining your bottom line. On top of this, the wasted money has an “opportunity cost.” The use of that money for other things, such as more advertising, sales staff, new crops or just putting it in an interest-bearing account, could actually provide a return.

Over the last year, we have done many projects at Interstate where we look at a grower’s total transportation cost outlay and analyze what the cost would have been if a properly focused and managed transportation outsourcing program would have been in place. The results are often very surprising and almost always in the favor of the grower using common carriers and logistics companies.

Remember, an outsourced transportation plan can take many forms. You may decide to work with a set number of “core” carriers. You may decide to work with one carrier. The key to every program, however, is its ongoing management and setting the correct expectations with your carrier partners. This starts with a simple communication plan and choosing the right partners for your needs.

Choosing The Right Partner

A good partner will be fairly priced — that is a given. But more importantly, it will provide better service than you could with your own trucks. Remember, problems with maintenance, drivers, breakdowns, insurance and DOT audits are now the responsibility of your core carriers, not you. Strategically, you should give them enough business to be important throughout the year, but not too much that they don’t have the extra “surge capacity” you need when the season hits its peak. You want core carriers that will divert capacity away from their other customers to fill your seasonal peaks. This comes from a simple “load allocation matrix” and will set out the seasonal expectations before the needs arise.

Common carriers, when managed correctly, will almost certainly save you money. Managing them correctly is the key. Using spreadsheets and white-boards will not cut it in today’s fast paced world. You need to look to automate your transportation needs using commonly found software (go to www.interstate-transport.com for more information).

So, the question begs, “Is there a situation when owning your own trucks does work?” The answer is yes. For growers, that almost exclusively means that to deliver locally (less than 100 miles or so), you need your own trucks. A common carrier will simply not be interested in your freight unless these “local” runs are part of a larger program.

The other scenario is if you are a huge shipper (with relatively consistent freight for 10 months or more each year) and you are willing to start your own common carrier trucking company. This will allow you to deliver to any location and get a “backhaul” load back to your nursery or nearby. This means your truck is full almost all the time with paying freight from either you or a third-party shipper. This decision takes some heart though. You will actually own a trucking company, along with all the headaches that come with one.

The vast majority of growers simply aren’t willing to take this difficult step. Those that do generally don’t stay in the trucking business for more than a year or two. If you are a large shipper, a good option is to outsource the trucking company operation to a proven carrier or logistics company and then provide them with office space at your location. They staff it, you use it. This can be the best of both worlds.

Hopefully you will make the decision to look closely at your transportation spending before the next season hits. The off season is the perfect time to see if outsourcing your transportation needs is right for you. The analysis will take you 30 to 60 days and the implementation 30 to 90 days depending on your expertise in this area. Most growers tell me they want to focus on growing and the trucking can be handled by those who have the expertise. Those growers are right on the money!