Greenhouse Grower’s Top 100 Growers Talk Technology, Automation, Sustainability, And Marketing

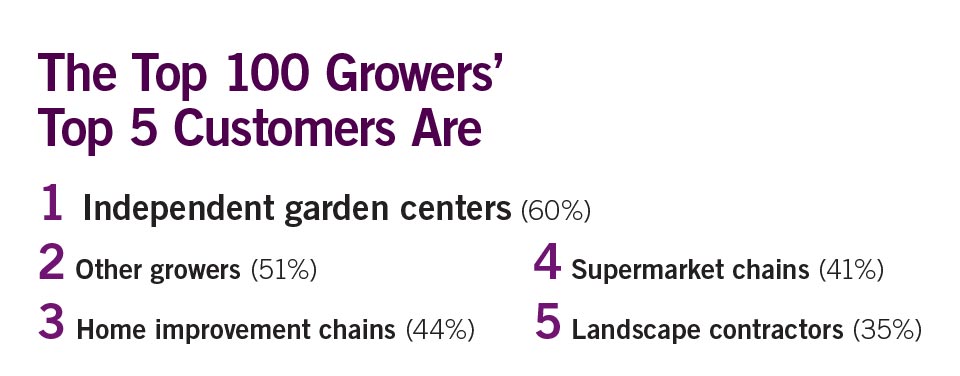

The Top 100 Growers are already by nature some of the most technologically advanced greenhouse operations, due to their sheer size and need for efficiency. Many of the largest growers also serve big box merchandisers and home improvement chains, where prices are dictated, so producing plants at the lowest possible cost is essential to growers not only staying in business, but also profiting and expanding their operations.

The Top 100 Growers are already by nature some of the most technologically advanced greenhouse operations, due to their sheer size and need for efficiency. Many of the largest growers also serve big box merchandisers and home improvement chains, where prices are dictated, so producing plants at the lowest possible cost is essential to growers not only staying in business, but also profiting and expanding their operations.

This year’s survey focused on the automation and technology the Top 100 Growers are investing in, and how these advancements have improved their operations, as well as how they have affected growers’ labor issues. We also asked growers about how they’re solving labor issues, where they’re recruiting new hires, and how they’re keeping their people committed. Lean management programs and sustainability certifications have become higher priorities in the past several years, due to growers’ needs to run efficiently and focus attention on sustainable production — both to minimize their effect on the environment, and to run responsible and profitable operations. We asked growers about their participation in these programs, and if they’ve noticed a difference in efficiency and profits as a result.

High-Tech Growers Like Everything Automated

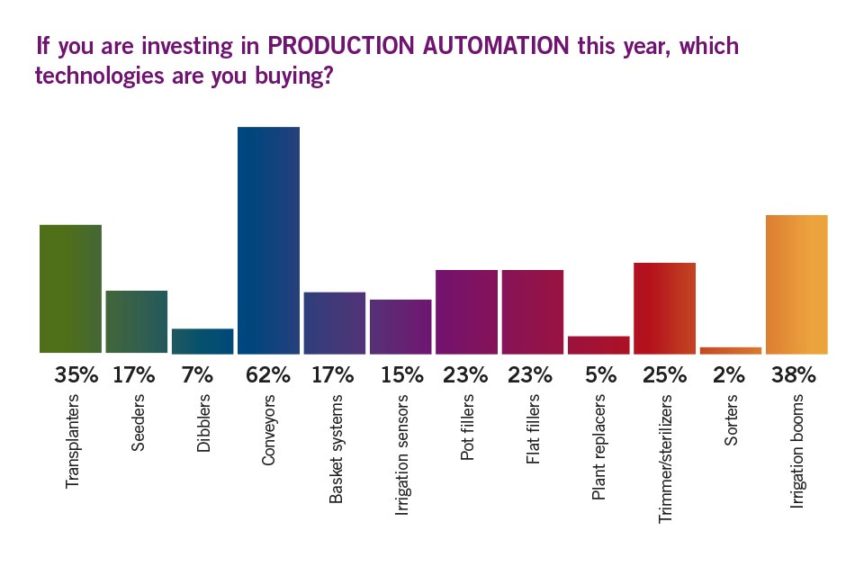

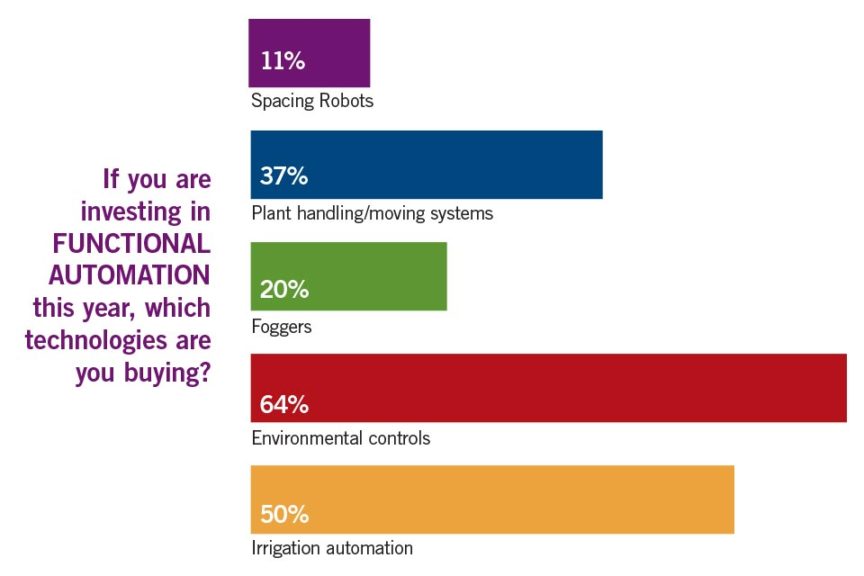

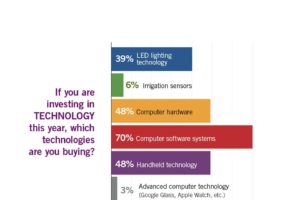

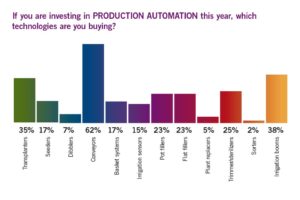

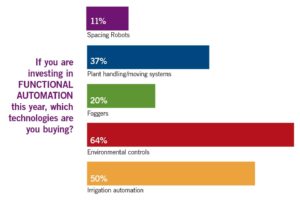

This is a big year for equipment manufacturers, as 77% of the Top 100 Growers said they are investing in automation equipment, including production and functional automation, technology, and equipment that will improve growers’ sustainability.

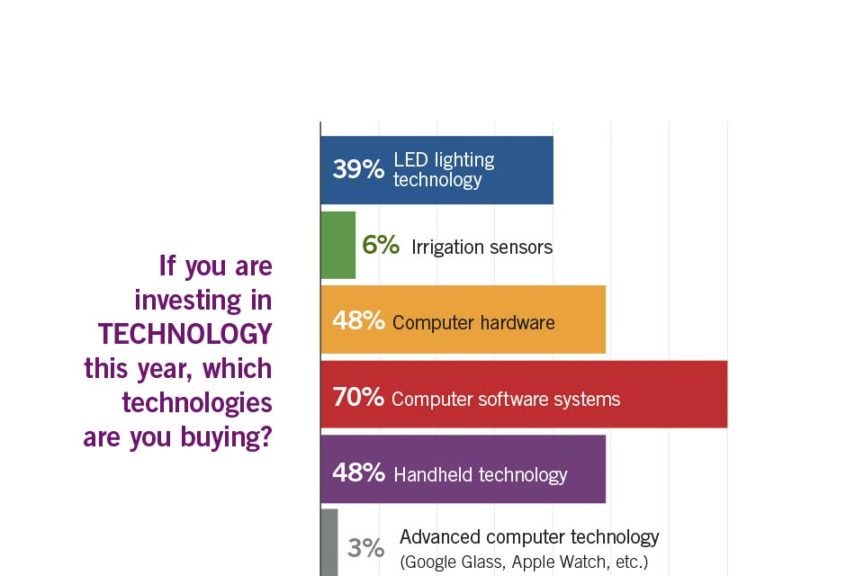

Factors that cause the Top 100 Growers to invest in technology include: improved efficiency (92%), cost of labor (71%), availability of labor (67%), better uniformity and efficacy of production (56%), expanding growing operations (38%), and to allow employees to concentrate on other areas (34%).

“The cost of labor is increasing incredibly in all regions, but especially in California where minimum wage has increased 25% in two years,” said Matt Altman, COO of Altman Plants. “Meanwhile in all regions of the Southwest, it has become more difficult to find people that want to work in the greenhouse. Machinery that can automate some of the tasks and increase productivity is one of the few methods we have to maintain costs. Adopting new technology and investing in automation is a must in this environment.”

The Top 100 Growers are an inventive group and have traditionally shown a high level of ingenuity in the engineering of new automation equipment for their operations. Most are intimately involved in working with automation and equipment and technology suppliers to customize their investments.

Growers said they buy base model equipment and tweak it on site to fit their needs (51%), or take a base model and work with suppliers’ engineers to tweak it to fit their needs (50%). They’ll also come up with their own ideas and build them on site (39%), and provide ideas for manufacturers to build, which often become adopted by other growers (33%). Eight percent of growers said everything they buy is engineered and customized for their operation, while 4% said they don’t customize anything.

“We do a lot of in-house fabrication. Since we are located close to nowhere, it gets costly to have it handed to us ‘turn-key,’” said Jonathan Cude, President/CEO of Sedan Floral.

Growers investing in technology to make their operations more sustainable are implementing heating technology (29%), alternative energy sources (21%), irrigation filtration systems (50%), and LED lighting (55%).

“Production has continued to become more streamlined and uniform,” said Cole Mangum, Vice President of Production at Bell Nursery USA. “By implementing standard operating procedures and best practices that are driven by technology, we can eliminate, to the degree possible, some of the variability inherent in greenhouse production.”

Art VanWingerden, co-owner of Metrolina Greenhouses, predicted, “Our industry will look vastly different 10 years from now than it does today when it comes to automation. I think we will see production lines that have six or fewer people on them. I think more and more greenhouses will look to some type of robotics for setting down product, spacing, and other tasks.”

Large Growers Are Growing Lean

Growers looking to streamline their production practices to improve efficiency have invested in lean manufacturing programs, including 42% of the Top 100 Growers.

“We have made a big investment in a year-long, university-led, leadership training program for our Top 100 managers to assure they are equipped with the leadership skills to handle their business and execute our five core company principles on a daily basis,” said Abe VanWingerden, Co-CEO of Metrolina Greenhouses.

Overall, 55% of growers who have taken part in a lean manufacturing process say the results they have observed have been what they expected, while 24% said their results exceeded their expectations, and 5% said the program didn’t measure up to expectations.

The lean process has resulted in labor savings in production labor, streamlining processes, increasing product output, and doing more with fewer people, for a number of growers.

“It has given us the opportunity to fine-tune processes and make each of them more efficient, thus helping to reduce operating expenses and also stay on target with production schedules,” said Cathy Kowalczyk, owner of Willoway Nurseries.

Other processes growers have invested in to make their operations more efficient include inventory management systems, process certification, investing in product transport equipment, streamlining shipping, and training and communication.

Big Growers, Big Labor Problems

Everywhere around the country, growers are finding the current labor shortage to be one of their biggest challenges, and they’re exercising a number of resources to secure enough production employees at their operations, including government programs like H-2A, internet and placement services, aggressive advertising, and in-house human resources departments.

Once they have production labor, they don’t want to lose it, so some of the practices they use to keep labor in place include offering good working and living conditions, paying higher than minimum wage, and offering full-time jobs with no layoffs in the off-season.

Trained, qualified growers have also been difficult to find and keep, with fewer students graduating from horticulture programs, and changes in priorities with younger generations, not to mention other operations recruiting their growers away.

“The biggest challenge when hiring growers just out of college is that they don’t have an understanding of the hard work this industry requires,” Chad Corso, President of Corso’s Perennials, said.

Randy Costa, Vice President of Headstart Nursery, said, “We find educated growers want to be the ‘President’ of the company within a short period of time. They are not patient.”

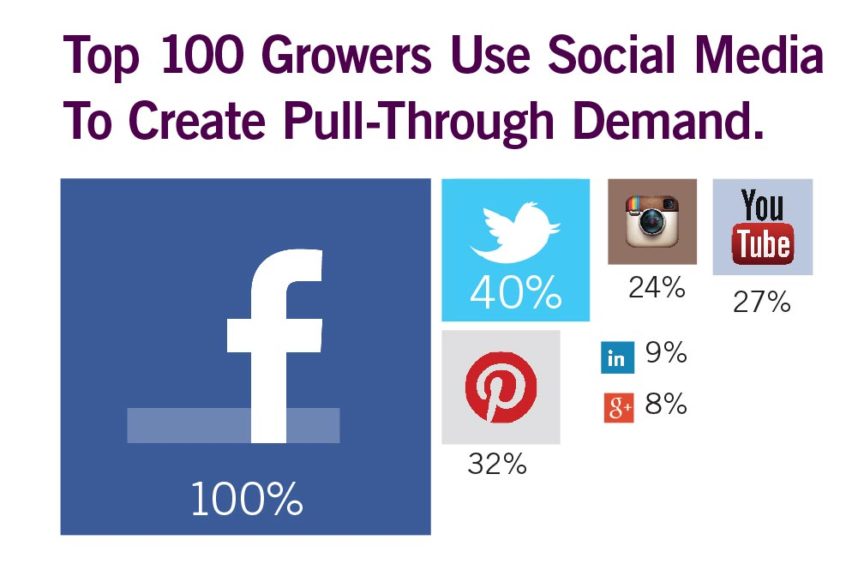

Working with universities and offering internships, employing headhunters, and advertising on social media have been crucial to recruiting young talent, and treating them well and offering them competitive salaries is key to retention, growers say. However, a shortage of qualified, university-trained growers has seen 80% of the Top 100 Growers train their laborers for grower positions in house.

Sustainability Is A Benefit Of High-Tech Greenhouse Production

Greenhouse growers have long been stewards of the Earth. The process of growing plants in a greenhouse is a sustainable practice in and of itself, but add to that the incremental practices growers have been adopting over the years, like collecting, recycling and reusing rainwater; investing in heating technology and alternative energy solutions; and reusing and recycling plastic pots, and the stewardship greenhouse growers display is far beyond most areas of agriculture.

Many growers have taken the initiative to track and audit their practices to ensure they are keeping up to standards set by retailers and other entities by enrolling in third-party certification programs.

Many growers have taken the initiative to track and audit their practices to ensure they are keeping up to standards set by retailers and other entities by enrolling in third-party certification programs.

Of growers surveyed, 20% have been certified through More Profitable Sustainability (MPS), 9% by VeriFlora, and 8% have been certified by a different program. Meanwhile, 33% said they have not been certified, and they’re unsure about how this would help their operations, 18% said they haven’t sought out certification yet but they plan to, and 12% have no interest in sustainability certification.

Certified-sustainable growers say they have realized a variety of efficiencies, including less water and chemical usage, more accountability from workers, better management and execution, and the comfort and pride of being in compliance with these standards.

Retailers have been enthusiastic about these programs in many cases, but others haven’t shown a preference either way.

“Some customers have embraced the certification and one even became a VeriFlora retailer,” said Jess Roethle, Corporate Facility & Purchasing Manager at Natural Beauty.

Whether growers are sustainability certified or not, they’ve made a bigger effort to educate their retail customers, as well as end consumers about their production practices. Some have found that consumers are interested, while others feel that their efforts fall on deaf ears, or that consumers are less than enthusiastic. However, they also say they know their customers will eventually be asking questions about their practices, so it’s in everyone’s best interest to be proactive and take the initiative before it’s mandatory.

Abe VanWingerden added, “Each of these areas (automation, technology, and sustainability) has to be part of your everyday process in the way you think through every business challenge. It cannot be a project.”