What’s In Controlled-Release?

In the first installment of this four-part series, we began to introduce several important aspects regarding controlled release fertilizers (CRFs). Slow-release fertilizers are reacted urea formaldehyde products. Each has its own characteristic chain of polymers, which are gradually broken off by microbial activity and then made available for roots to uptake. Controlled-release fertilizers are fertilizers with nutrients that are encapsulated or coated, similar to an M&M candy, where there is an outer candy coating and the good stuff inside the coating. Fertilizer is released when moisture is drawn into the covered coated prill and turns the fertilizer salt into a semi-soluble form. The release of nutrients from the prill varies slightly with the technology used to formulate the coating.

All CRFs typically have either a resin or polymer coating. The main difference is how the water soluble fertilizer comes out of the prill. The rate of release is often a function of the technology used for the coating, production temperatures and the thickness of the coating.

Now we continue our discussion regarding controlled release fertilizer technology and how to develop a CRF plan that will fit production needs.

Pilon: I’ve heard the term ‘homogenous’ when discussing fertilizers in the past. What does this mean and are all CRFs homogenous?

Passchier: The American College Dictionary defines homogenous as “composed parts all of the same kind, of the same kind or nature.” In the horticultural industry, homogenous means that a controlled release fertilizer particle contains at least nitrogen, phosphorus and potassium all within the same particle. Again, using M&M candy as an example, they may contain milk chocolate or milk chocolate and peanuts on the inside, but each piece of M&M candy is homogenous since all of the ingredients are on the inside and every candy within a bag is identical.

To better understand homogenous products, it is often helpful to understand the opposite of homogenous–heterogeneous. A heterogeneous product consists of a mixture of individually coated single elements. For example, the nitrogen is one coated granule, the phosphorous is another coated granule and potassium is the final coated granule. When looking into a bag of heterogeneous fertilizer, all of the prills may look similar because the coating makes them appear similar and with particle sizing technology, even the size of the individual nutrients is almost impossible to pick out.

Homogenous NPK (nitrogen, phosphorus and potassium) products not only contain NPK and certain minors in one granule, but with the same amount of coating on each prill, the release pattern of all nutrients may be the same. There are products that have homogenous NPK available with a specific release pattern, but most successful growers using CRFs prefer to blend a combination of release pattern products (a heterogeneous blend) which release over a two- to nine-month time period. With the aid of computers and field observations, such fertilizers as Diffusion Fertilizers, have release patterns of heterogeneous and homogenous NPK products that have been successfully engineered for different crops and temperature areas.

Pilon: Are micro-nutrients included in homogenous products?

Passchier: There are homogenous fertilizer NPK products that do and there are those that do not contain micro-nutrients. In theory, the advantage to using products with homogenous micro-nutrient sources is the micro-nutrients become available over a period of time and are available as the NPK is released from the fertilizer-coated granule. The disadvantage may be that the micro-nutrient levels released are too low for adequate plant growth and may result in nutrient deficiencies under certain circumstances.

Pilon: What types of nutrients do CRF fertilizers contain?

Passchier: Most CRF nursery and greenhouse formulations contain the macro-nutrients: nitrogen, phosphorus and potassium. Several products contain the secondary nutrients: calcium, magnesium and sulfur; and often contain several micro-nutrients such as boron, copper, iron, manganese, molybdenum and zinc.

Pilon: With CRFs, does the source of nitrogen matter?

Passchier: I personally think that with CRFs, growers are looking for consistent results when growing their crops. I also believe growers want to use fertilizers as efficiently as possible. I use the phrase “maximum production with minimum input” when referring to how growers prefer to produce crops. There are two main efficiency factors that influence the nitrogen use of containerized crops.

The first influencer is the crop itself and the production practices it is being grown with. Is it growing in such a healthy state that it can use the fertilizer that is there for its consumption? Does the porosity of the growing media allow adequate availability of oxygen for healthy root growth? Do the watering practices maintain a healthy air and water ratio in the root zone? Does the volume of irrigation applied minimize leaching of nutrients? A healthy and properly managed plant will use nitrogen efficiently whether it is from ammoniacal, nitrate, or urea sources.

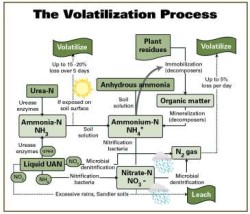

The second influencing factor is the frequency and severity of nitrogen losses from the nitrogen cycle. When growing in mineral soils in field situations, we often look at nitrogen losses from leaching and volatilization. It may be good to review these basics and to consider how it affects container crops produced in greenhouses and nurseries. The two predominant factors that affect nitrogen loss in both mineral soils in field scenarios and container substrates are leaching and denitrification of the nitrate form of nitrogen.

All nitrogen-applied fertilizers eventually are converted to the nitrate-nitrogen (nitrate-N) form, even when they are coated to make them controlled release. The nitrate-N form is loosely held in our soils and is subject to leaching. With poorly drained and/or overwatered soils and growing mediums, such as high peat moss substrates (in certain situations), certain anaerobic bacteria may convert nitrate-N to oxygen and nitrogen gases, thus the loss of nitrogen through volatilization.

Fertilizers containing urea have received somewhat of a bum rap in the greenhouse and nursery industries and it could be due to a lack of understanding. Remember, with controlled release urea, the nitrogen is released over a period of time in small amounts. Even with the small amounts of urea released, if the conditions are right for volatilization and leaching, it will occur. With a greater understanding of what influences the leaching and volatilization of urea, growers will be able to use all nitrogen sources more effectively.

When coated ureas are surface applied, the urease enzymes convert the released portion of the urea components to free ammonia gas. If this conversion takes place on the soil surface and is accompanied by warm sunny days, volatilization could occur. A soil surface pH of 7 or higher also may have an effect on the volatilization. This is particularly the case in over-wintering structures such as hoop houses and tunnels, which are often covered with poly films and may or may not have irrigation or ventilation abilities. We have learned from field operations that when the urea is watered in after the release in the first 24 hours, the risk of volatilization essentially drops to zero. When growers manage their crops to minimize volatilization, they can use urea successfully. This means having water and ventilation available when the conditions are right for volatilization and free ammonia in the over-wintering structures. Very seldom do growers observe issues with urea volatilization of free ammonia in well-ventilated greenhouses or open air nursery situations.

With technology of coated homogenous ammonium nitrate products and potassium nitrate products, combinations of urea, ammonium nitrate and potassium nitrate can be engineered and formulated so growers can successfully use these products in hoop houses, tunnels and greenhouses.

Secondly, the correct release patterned urea products in combination with ammoniacal and nitrate nitrogen sources have significantly less or no volatilization when incorporated in the soil. It is very important for a grower’s fertilizer supplier and formulator to understand precisely when the different nitrogen sources are to be released.

Pilon: What are the advantages of using urea versus nitrate nitrogen?

Passchier: From industry watercooler conversations, I hear people saying a nitrate-based fertilizer grows a more compact plant and achieves very nice leaf expansion when using some controlled-release urea in the formula. There are places for ammonium nitrate, nitrate nitrogen and urea-based CRF fertilizers. In many instances, it comes down to an individual grower’s personal preference based on past experiences and cost.

Pilon: In a greenhouse, is ammonium toxicity a concern?

Passchier: The word toxicity means there is a concern, but when you manage your crop to grow in a healthy environment, the chances of ammonia toxicity is minimal. If there is a healthy growing environment with a healthy micro-organism population for converting nitrogen, the likelihood of ammonium toxicity is greatly minimized. Poorly drained, heavily watered, anaerobic soils are not good environments for growing plants. Avoid these conditions and ammonium toxicity is usually not an issue.