Getting Results With A Liner Dip

Controlling plant height is a key factor in producing a quality crop and maximizing the number of plants that can be shipped per rack. Growers often use both chemical and non-chemical height control techniques to suppress stem elongation. Plant growth regulators (PGRs) are commonly applied as foliar sprays, media drenches or sprenches (high-volume spray with runoff into the media), depending primarily on the duration of the desired response.

A PGR application method that is being increasingly used by greenhouse growers is referred to as a “liner dip” or “plug dip.” This application method involves placing a plug tray in a shallow PGR solution, allowing the chemical to absorb into the growing media. After the chemical application and when plants are safe to handle, the young plants are subsequently transplanted into finish containers. A plug dip can be very effective on vigorous species and provide a moderately long-lasting response. There is also less potential for a flowering delay because the chemical does not contact the tops of shoots where flowers develop.

The plug dip method provides the opportunity to treat young plants before planting a mixed combination container. Combo planters often include plant species with different growth habits and development rates, thus conflicting PGR requirements. Aggressive species can grow too fast and quickly dominate the container, outgrowing less vigorous species (Figure 1). A PGR applied to the mixed container as a foliar spray or media drench would also affect the less-aggressive species, further suppressing its growth. The application of a PGR to plugs of the aggressive species before transplant as a plug dip could overcome this challenge and improve the quality of mixed containers.

Keys To Success

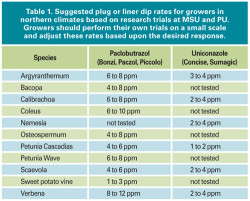

Although many growers have been successful with PGR plug dips, some growers have noted concerns about inconsistent responses between applications. During the past several years, researchers at Michigan State University, the University of Florida, and Virginia Tech have performed many PGR plug dip trials to determine appropriate application rates for bedding plants and herbaceous perennials, and to learn which factors can influence the response. Below are four keys to success to ensure the best results with PGR plug dips.

1. Use the correct plug dip rate: The rate influences how much active ingredient is absorbed by the media and, thus, the magnitude of height control. For example, plugs of sweet potato ‘Blackie’ dipped for 30 seconds in Piccolo (paclobutrazol) at 4, 8 or 12 ppm were 24, 29 and 39 percent shorter than non-treated plants when measured six weeks after application (Figure 2). Application rates that are too high will cause excessive suppression of stem elongation, and the crop may not finish on schedule or be of low quality. For example, stem elongation of bacopa ‘Falls Big Pearl’ was severely retarded in plugs dipped in 12 ppm Piccolo for 30 seconds, and plants were on average 7 inches shorter than untreated plants at four weeks after application (Figure 3).

Plug dips are effective using products that are absorbed by roots and translocated to the growing shoots, which include products containing paclobutrazol, uniconazole, flurprimidol or ancymidol. We recommend that growers perform their own trials on a small scale to determine the best application rate for their growing environment, crop and desired response. Application rates for plug dips may be comparable to those used for drench applications.

2. Control your media moisture content prior to the dip: The moisture content of the plug media will influence how much of the chemical solution is absorbed during the dip. A plug with dry media at the time of application will absorb much more chemical than a plug with wet media. For example, dry plugs of petunia ‘Wave Purple’ dipped in Piccolo for 30 seconds were 5 inches shorter at six weeks after application than plugs that had moist media at application (Figure 4).

Plugs along the edges of a tray usually dry out faster than those in the middle. Large variations in moisture content can lead to inconsistent plug dip responses. A good rule of thumb is that plug trays should be only slightly dry at the time of application. In our research greenhouses, this was accomplished by irrigating plug trays during late afternoons and making the PGR application on the following morning.

3. Timing is important: The duration that the plug tray is in the PGR solution can influence how much of the active ingredient is absorbed by the media. Research at the University of Florida showed that if the plug media was dry at application, there was little difference in response between dip durations of 30 seconds and 2 minutes. Very short dips (less than 10 seconds) are not recommended because the volume of PGR solution absorbed can be more variable. Thus, we recommend that growers begin with a dip time of 30 seconds and adjust the duration if necessary.

4. Develop a repeatable application procedure. The best way to prevent inconsistent responses with a PGR plug dip is to develop a repeatable application procedure. Growers should perform small trials to determine appropriate rates and the best dip duration for each crop. Just as critical is to control watering of the plugs and liners before the dip so that the media is consistently and uniformly slightly moist. Be sure to take notes and document the application protocol and the plant response. You may also wish to leave some plugs untreated to document the relative response of the plug dip to non-dipped plants.

Other Important Factors

The degree of root development and quality of the plug have been shown to have a slight influence on the plug dip effectiveness. A PGR dip on plugs with less root development can cause greater height suppression than mature plugs with a well-developed root system. The depth that the plug tray is in the solution has little influence on the PGR response. In our greenhouse, we place each plug tray in the chemical solution so that the PGR solution level is approximately 50 percent of the tray height.

Sanitation and proper disinfection are important to avoid transferring diseases among crops. Remember that after the chemical application, plugs should not be transplanted until after the restricted entry interval (REI) for the product, most of which are 12 hours. Plugs can be held and transplanted several days after the PGR dip without reducing the effectiveness of the application.

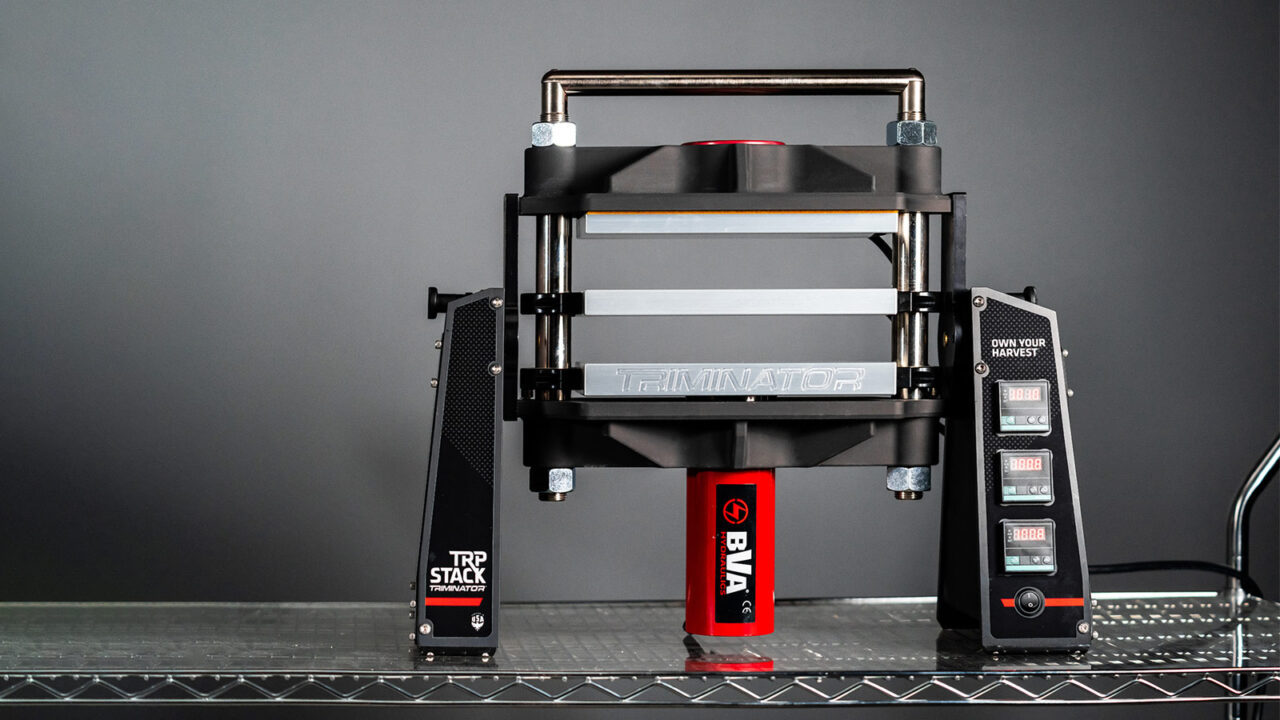

Large-scale greenhouse operations that treat hundreds of trays with a PGR may aim to automate the plug dip. For example, trays could move on a conveyer and pass through a PGR solution (Figure 5). The speed of the belt will need to be adjusted so that plants absorb a desirable amount of PGR solution. Although expensive, this kind of system helps ensure uniform and repeatable results from a plug dip.