Producing Consumer-Friendly Baskets

Growers have come under pressure to improve the lasting quality of their containerized plants. In this six-part series, we will discuss a number of options for making baskets and large containers more consumer friendly. In part one, we will discuss media selection and available water-holding capacity and their effects in keeping plants alive through the summer. The key concept is that containers with high available water-holding capacity require less irrigation by the consumer, but require extra care to avoid overwatering during greenhouse production.

Understanding Physical Properties

A container root medium is like a sponge. A sponge is made up of holes (called pore spaces) and solids (the medium itself). If you soak the sponge in water and then allow it to drain, the larger holes (called macropores) will have drained and now be filled with air (air space). The smaller holes (called micropores) will have retained the water (water space). The exact ratio between air and water will depend on the height of the sponge (height of the pot), with tall sponges having, on average, more air space and less water space than a shorter sponge.

The maximum volume of water that a root medium can hold after an irrigation (water holding capacity) therefore depends on the physical properties of the root medium, along with the height and volume of the container.

The water held in a root medium can be further broken down into two fractions, available water and unavailable water. Available water is the fraction the plant can extract from the root medium and use for transpiration. Unavailable water is the fraction that is bound so tightly to the medium itself that the plant can not extract it. In general, most of the water contained in a soilless root medium is available to the plant.

Available Water-Holding Capacity

Available water-holding capacity of the root medium is one of the better predictors in how long a plant in a large pot or basket will go between waterings.

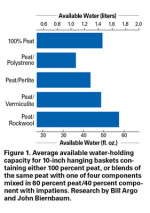

In evaluations of impatiens grown in 10-inch hanging baskets testing different components blended with one type of peat, available water-holding capacity of the blends increased in the order: polystyrene < perlite < vermiculite < rockwool (Figure 1). The 100 percent peat medium had an available water-holding capacity similar that of the peat/vermiculite blend.

After being grown nine weeks in a greenhouse and 11 weeks outside, plants grown in the peat/polystyrene, peat/vermiculite and peat/rockwool blends were similar in size, while the plants grown in the peat/perlite and 100 percent peat media were noticeably smaller. For similar size plants, the average days between watering was 3.5 for the peat/polystyrene, 4.8 for the peat/vermiculite and 6.1 for the peat/rockwool.

Another gauge of a root medium’s ability to supply water to a plant is the minimum days to water, which is a measure of an available water supply during to the plant under hot, dry conditions. This also increased from one day for the peat/polystyrene, two days for the peat/vermiculite and three days for the peat/rockwool.

In a separate experiment testing impatiens grown in 18 commercially prepared root media, the available water-holding capacity ranged from 51 fl. oz. (1.5 liters) to 77 fl. oz. (2.3 liters). Average days between watering ranged from 3.7 to 6.3 days and minimum days between watering ranged from two to four days while being grown outside during the summer.

In this second group of experiments, neither the available water-holding capacity nor the time between watering could be predicted by the components used to produce the root medium. For example, a root medium containing a fine peat with polystyrene had a greater available water-holding capacity compared to a course peat/perlite/rockwool medium.

The difficulty in predicting available water-holding capacity based only on the formulation of the media is that different grades of each component will vary in their water-holding capacity. For example, fine peat tends to hold more water than course peat. Several alternative component/peat blends can end up having identical available water-holding capacities. If you are considering a change in root media and you want to use high available water-holding capacity as criteria, then you need to be able to measure it in your greenhouse to make comparisons (see sidebar).

Problems With High Available Water-Holding Capacity Media

A reason often used by growers when choosing a root medium for basket or large pot production is “good drainage.” By this they mean small plugs can be directly planted into the basket in January or February, placed on drippers and have low risk of overwatering. Remember, a pot or basket has a fixed volume, so using root media with higher available water-holding capacities can cause some challenges.

With high available water-holding capacity media, there are several management strategies to prevent over watering early in production:

1) Transplanting larger plant material with a more developed root system;

2) Maintaining the baskets on a bench or floor close together for the first few weeks so watering can be more controlled and possibly done by hand;

3) Production in baskets with external saucers that can be left off to provide drainage during production but attached prior to shipping to increase the amount of water retained; and

4) Instructing growers to weigh baskets and not to water until they reach a predetermined weight. These methods may not be practical due to scheduling and labor concerns but should be considered.

Available water-holding capacity is a key criteria for producing consumer-friendly baskets and large pots. Next month, we’ll discuss other ways to extend the time between waterings.