The Latest Advancements In Growing Media And Soils

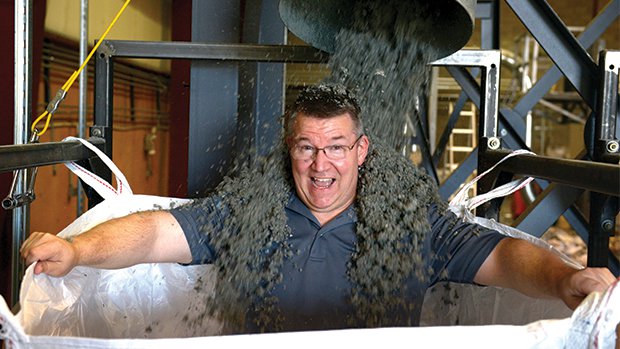

PittMoss is an engineered fiber, comprised of recycled newspaper and other natural materials, that has been processed to better hold air and water while delivering nutrients to the plant. Pictured: PittMoss founder Mont Handley

From organic ornamentals to rain gardens, consumers are increasingly focused on conservation and green practices. As their customers continue to demand sustainable alternatives, growers have responded to meet these needs, leaning on product companies for efficient and cost-effective options. The reaction has been swift.

Here, growing media manufacturers talk about the latest technologies and trends, as well as their commitment to an eco-friendly future.

The Tech Advantage

A big part of being able to provide better sustainable options means having the right machinery.

“Growers have access to an increased level of technology, equipment, controllers and sophisticated programs. That is a clear trend,” says Jean-Pierre Fortin, research and development technical director for Fafard et Frères. He says he sees this as a way for growers to cut costs and better manage production. It’s also prompted the peat company to continue finding new ways to optimize its mixes at the ingredient and process levels.

“This allows soil mixers to market mixes that can be handled for faster, better crop quality,” Fortin says. “Ultimately, the soil technology must overcome parameters such as air porosity and drainage and provide growers with a clear understanding of dynamic and specific properties that they can use to optimize crop development.”

In order to enhance their media, growers are also looking to incorporate technologically superior materials. At PittMoss LLC, Charles L. Bethke has noticed this trend firsthand. For example, PittMoss, an engineered fiber comprised of recycled newspaper and other natural materials, has been processed to better hold air and water while delivering nutrients to the plant.

“[In the next few years,] more recycled products will be remanufactured and scientifically altered to provide the best physical, chemical and biological properties, while having desirable handling properties,” says Bethke, who says he sees the next generation of growing media as a delivery system for pest control solutions, nutrients and plant growth regulators. “Substrates that serve as carriers of materials to ensure consumer performance will be more highly valued.”

Growers benefit from new technological advancements in other ways, too. Better machinery almost universally results in labor savings — a major pain point for growers of any size.

“Growers are definitely trying to automate more. They are continually introducing high-tech machinery and robotics,” says Otto S. Kaufmann Jr., national account manager for Lambert Peat Moss. “They’re adding machinery to maximize production of their mixes.”

As the bigger operations continue to expand and growers become more specialized, Benoit Corbeil, sales director at Berger, says automated systems are in high demand.

“This translates to a need for a more consistent and uniform growing media,” he says, adding that Berger is developing products that simplify things for the grower. “We are working on mixes that are adapted to specific food crops — some of which are already available on the market — and on a succulent growing media that is optimized to meet the particular growing requirement of this crop.”

Organics And Other Trends

Ask soil and amendment manufacturers what their grower customers want and the answer inevitably contains the words organic, sustainable or custom. More movement than trend, green industry product managers are expanding their offerings, media companies included.

“It seems to be going from a niche market to becoming more mainstream,” says Dan Jacques at Sun Gro technical services. He says the industry is moving toward custom blends with biological organisms that enhance growth and resist diseases.

“We see growers moving away from traditional pesticides and using environmentally friendly products,” says Ed Bloodnick, director of grower services at Premier Tech Horticulture. The company has introduced several Pro-Mix product lines that contain biofungicides and mycorrhizae to address specific grower needs while enhancing plant performance.

”This is becoming more evident as growers diversify into the edible market.Organic mixes and bioadditives address this growing trend.”

Attention Shifting Toward Environmentally Friendly Soil Components

Kathryn Louis of Sun Gro regulatory and technical services says another trend in the industry has been the move away from the sustainable label to looking more at whether or not components are environmentally conscious. She says interest in Sun Gro’s natural and organic mixes has increased significantly.

“Media containing components such as Canadian sphagnum peat, composted bark, coconut coir and locally available composts fall into these categories.”

PBH Nature’s Media Amendment doubles as a water-saving soil additive and a topdress to control weeds

As growers continue to pay attention to soil components, media companies are incorporating more diverse ingredients. Theriault & Hachey Peat Moss offers a wide variety of custom-blended growing substrates in order to help meet its customers’ demands.

“There’s no longer one standard product; it’s not a one-size-fits-all as it has been in the past,” says Jody Williston, Theriault & Hachey Peat Moss’ vice president of sales and marketing. He says that even small growers want specialized mixes for their operations.

“By rigorously selecting our ingredients and treating them with respect throughout the processing, mixing, storage and shipping processes, we are able to create various mixes for different markets, climates and budgets.”

In addition to environmental concerns, overall cost still plays an enormous role in product selection.

As Fortin says: “Sustainability is always a concern, but most growers have profitability in mind. It is up to the soil media manufacturer to offer sustainable solutions.”

Many manufactures agree. “We believe environmentally wise solutions continue to be important to growers. This is especially true if the sustainable solution is easily incorporated into the existing production program, does not escalate costs and offers benefits not found elsewhere,” says Scott P. Johnson, commercial director at Riceland Foods, the company that manufactures PBH Nature’s Media Amendment, a rice hull alternative to perlite in growing media.

“Change does not — and should not — happen overnight,” Johnson says. “But new components offering real advantages and trialed by growers looking for better solutions can certainly find a place in the greenhouse grower market.”

PBH Nature’s Media Amendment, for example, is cheaper and less dusty than perlite. In addition to boasting a high water-holding capacity that saves growers money on irrigation costs, Johnson says the OMRI-listed product can double as a topdress to control weeds.

Products that can multi-task are certainly in high demand.

“Our customers are asking, ‘How can I grow while using less inputs? What can I reduce that won’t impact plant quality?’” says John Wynne, business development manager for Evonik Corporation, which produces a superabsorbent hydrogel called Stockosorb that acts as a moisture buffer throughout the production and retail process. “Growers are looking for ways to maximize their media, squeezing it to do all it can for the plants.”

Planning For The Future

Resource preservation can be an especially touchy subject, particularly with respect to peat moss.

“When the issue of sustainability comes up, I am quick to show peat moss is sustainable,” says Williston.

Otto S. Kaufmann Jr. of Lambert agrees, saying his company has only had to refurbish one peat bog since 1928. The peat bogs are replenishing 70 percent faster than the company is harvesting, which amounts to approximately one inch per year.

Many companies have worked on peat bog restoration projects for years.

“Old peat bogs that are no longer in use are brought back to be live bogs where the sphagnum moss grows and spreads,” says Søren Møller Nielsen, national sales manager for Pindstrup, a company with more than 100 years of experience in the peat business. “We draw on our long experience in handling peat bogs and have developed various techniques to bring the live moss back.”

After all, this level of sustainability is important to growers, too.

“They seem to like the idea of doing their part to improve the environment,” PittMoss’ Charles L. Bethke. “They practice good stewardship in using the resources at hand.”