The Processing And Properties Of Pine Wood Chips

Over the past decade, there has been a lot of talk, debate and research conducted on the discovery and use of alternative substrates and substrate components. More information has been generated in recent years than at any other time since the 1960s and ’70s, when the first peat-lite mixes were introduced as substrates for greenhouse crop production.

The most discussed and researched new material/component has been the use of freshly processed pine wood/trees. These pine tree substrates (PTS) have proven successful when used in greenhouse and nursery mixes, mainly as a peat/bark-extender or peat/bark-alternative. It has been suggested that the use of these wood components in peat-based mixes could deem perlite unnecessary due to the aeration (increase in porosity) that the wood components create in the substrates; however, no specific information or research has fully investigated this claim.

[blackoutgallery id=”58050″]

Alternatives to perlite have been thoroughly investigated over the years primarily because perlite is the most expensive substrate component (by volume) due to the costs associated with mining, heating and transporting the material. While perlite does a wonderful job as an aggregate in peat-based mixes, its particle size can be variable (affecting the porosity in mixes), and the well-known dust it emits during handling can be a nuisance for workers.

In 2010, researchers in the Horticultural Substrates Laboratory at North Carolina State University (NCSU) began investigating the engineering and processing variables that influence the consistency and ability to reproduce traditional and alternative substrate components. These researchers (Brian Jackson and Bill Fonteno) began a different approach to substrate research, one that “began with the end in mind.” They focused on how to better understand the engineering and processing of pine tree substrate components to be better able to recreate them, utilize their potential and make them into more “value-added” components. Specifically, one of the main goals was to create a wood aggregate that could be an effective and cheaper alternative to perlite.

Pine Wood Chips Versus Perlite

Pine tree substrate materials have traditionally been produced from freshly harvested loblolly pine (Pinus taeda) trees that were chipped and then further processed in a hammer mill through screen sizes ranging from 3/16- to 3/8-inch. The resulting end product contained a mix of particle sizes and shapes, mostly being a fibrous-like material. It was the mix of fibrous particle sizes that gave the material water-holding properties similar to some peat and pine bark substrates.

To produce a non-fibrous wood component, it was discovered that changing the size of the coarse wood chips (using different machines to chip the pine logs) and adjusting the moisture content of the wood chips prior to hammer-milling yielded consistent non-fibrous small pine wood chips (PWC) that can be used specifically as substrate aggregates. When coarse wood chips are processed in a hammer mill through a ¼-inch screen, the end product is PWC that has the same particle size as a coarse-grade perlite. Because different aggregate sizes are needed for different substrate mixes (propagation, plugs, bedding plant flats, one-gallon pots, etc.), the screen size used to process the wood chips can be changed to produce smaller wood chips. So, like perlite, different grades/sizes of PWC can be constructed.

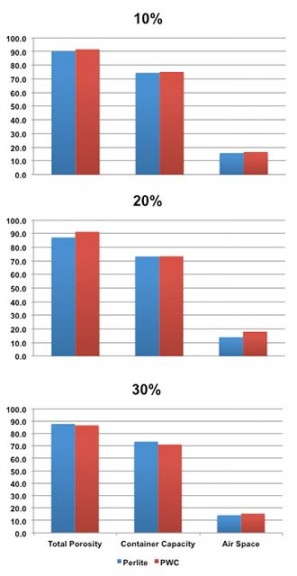

A full range of laboratory testing was conducted on PWC to determine the exact properties of this material. Particle sizes, moisture release curves, drainage profiles, hydration efficiency and physical properties including total porosity, air space, container capacity and bulk density were determined. The PWC were tested against perlite in all studies to compare the differences and/or similarities between these two aggregates.

Both aggregates were amended to peat at rates of 10, 20 and 30 percent, which cover the general range of amendment percentages that growers would use in their greenhouse mixes. At each aggregate rate tested, there were no differences in the substrate physical properties. Higher rates (>30 percent) were also tested and at the higher rates, more air space is found in mixes containing PWC compared to perlite.

After thorough and repetitive testing, results remained consistent that PWC can replace perlite in a peat substrate with the same resulting change to substrate porosity (air and water percentages). Even though perlite can be completely substituted with PWC with no change in physical properties, the addition of 3 to 5 percent perlite to mixes may still be needed since the general public (consumers) has the perception that the white particles of perlite are actually fertilizer.

Cost Performance, Uses And Production Of Pine Wood Chips

The estimated cost of PWC, including the acquisition of pine trees, equipment to process the trees, and actual manufacturing (energy, man hours, etc.) will be 40 to 50 percent cheaper than perlite. Further assessment on the economics of PWC commercialization is being investigated.

Since the development of PWC in 2010, dozens of plant growth trials have been conducted to investigate their use as aggregates in greenhouse substrates. These plant trials included numerous summer and fall annual species, perennials, vegetable transplants and seasonal floriculture crops (mums and poinsettias). General observations during these trials show that the PWC aggregates do not decompose during crop production (no shrinkage), and they barely change color (they remain the yellow color of fresh pine wood) if at all. Another observation made numerous times over the past several years is the quality of the root growth of plants grown in mixes containing PWC and other wood substrate components.

University researchers, substrate manufacturer R&D personnel and some growers have independently commented on the exceptional root growth that many plants will have. There are several possibilities for why this is occurring but no solid evidence is currently able to explain it fully. Additional research results will be released in the near future to cover important cultural information about the use of PWC in greenhouse crop production, including fertility practices, lime/pH modifications, plant growth regulator efficacy and aging/phytotoxicity concerns.

Despite the traditional uses (pulp, paper, timber, fuel, etc.) and more recent uses (wood pellets, biofuels, etc.) of pine trees in the United States, it is still believed that pine wood is a reliable source of sustainable greenhouse substrate components in the foreseeable future. The Southeastern United States is one of the most abundant wood-producing regions in the entire world and production (acreage) continues to be more productive, thanks to innovations in tree genetics and silviculture practices.

It has been mentioned in the past that a grower, consortium of growers, substrate manufacturer(s), or other private entrepreneurs could intentionally plant pine trees for the specific purpose of growing them for use in horticultural substrates. Since the ideal tree age for processing is between 12 to 14 years (depending on planting density, soil type, fertility, etc.), the turnover in acreage would be relatively quick. It is unknown at this time how much PWC or other pine wood components could be produced from an acre of land planted dense enough to be uniformly harvested at one time (which is unlike current pine management practices). Much work continues at NC State University at the Substrate Processing and Research Center (SPARC), constructed in 2014, to better investigate the engineering and utilization of traditional and alternative substrates.