How to Improve Customer Success by Adding Residual Fertilizer to Your Plant Products

As an industry, we do a great job with genetics as a means to improve plant quality. Breeders introduce beautiful new cultivars in every trade show and variety trial. However, if we are producing a premium plant, it should look its best when it leaves the greenhouse and beyond.

One way to support customer success is to ensure that plants have adequate residual fertilizer, such as polymer-coated controlled-release fertilizer (CRF), after sale. Many consumers are not going to add fertilizer to the soil or pot. We should be asking our consumer to just add water, and if we can even take care of that with drought-tolerant plants grown in large pots with a reservoir, all the better.

Fertilizer Strategies

We ran a trial at the University of Florida where a vigorous petunia cultivar, ‘Supertunia Vista Bubblegum,’ was grown for two phases that represented the grower (production) and homeowner (consumer) environments.

Rooted cuttings were transplanted into trade 1-gallon containers filled with a 70% peat/30% perlite mix without a pre-plant nutrient charge.

Production phase: During six weeks of greenhouse production in a 1-gallon pot, we used several strategies to fertilize plants, all of which provided a marketable product (Figure 1). These strategies included:

(a) Water soluble fertilizer (WSF, or fertigation), at 200 ppm nitrogen (N) of 15-5-15 with each irrigation

(b) CRF (5- to 6-month 18-6-12) incorporated before planting at 10 lbs/cubic yard

(c) Combinations of a low rate of both WSF (100 ppm N) and incorporated CRF (4 lbs/cubic yard)

(d) WSF at 200 ppm N, with a delayed-release (double-coated) CRF incorporated before planting at 10 lbs/cubic yard.

Many greenhouse growers choose strategy (a) WSF because of the ease of controlling applied fertilizer concentration, and low production cost.

Growers who produce plants outdoors with high rainfall often use strategy (b) CRF to simplify fertilizer management, and to avoid the need to add water each time plants need nutrients (which may saturate an already wet growing medium). Nursery growers with sprinkler irrigation typically use CRF with clear water irrigation, so irrigation water that is not intercepted by the container does not waste fertilizer.

A low rate of CRF (strategy (c)) can be added to the most vigorous varieties during production, with no CRF added to slower-growing crops. In this way, one concentration of WSF can be used to fertigate a wide range of crop types that include high or moderate fertilizer needs.

Strategy (d) is a new technology that allows growers to produce plants with WSF, without nutrient release from the double-coated CRF occurring until the consumer phase. The fertilizer used in our trial was a double-coated 5- to 6-month, 18-6-12 product from ICL called Protect. This product has a second outer coating over a CRF prill, which delays the initial nutrient release for four to seven weeks depending on temperature. Many of the benefits of double-coated CRF could probably be achieved by using a single-coated CRF that has low initial nutrient release, but has a release pattern that is longer than the production phase.

Consumer phase: WSF alone provides minimal residual fertilizer for the consumer. Within one to two weeks, especially if water is poured on in the retail or home environment, WSF will rapidly be used up or leached out.

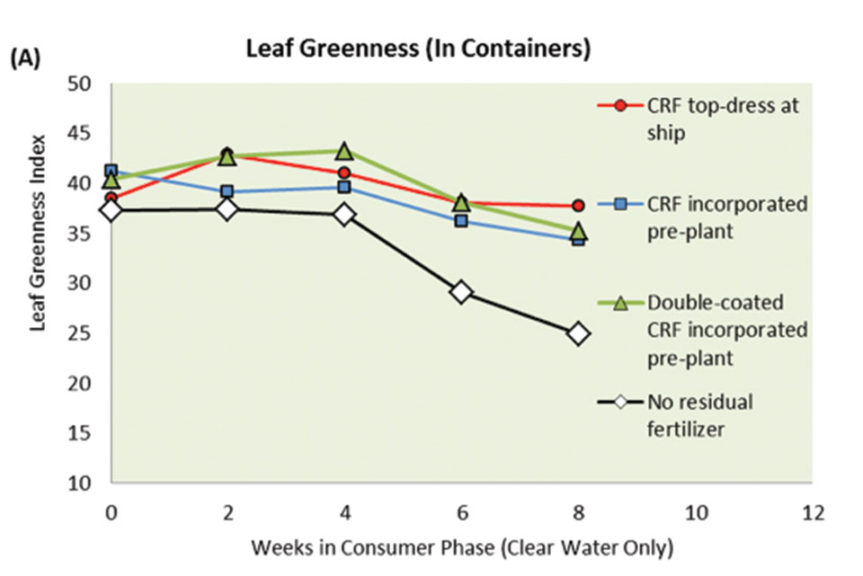

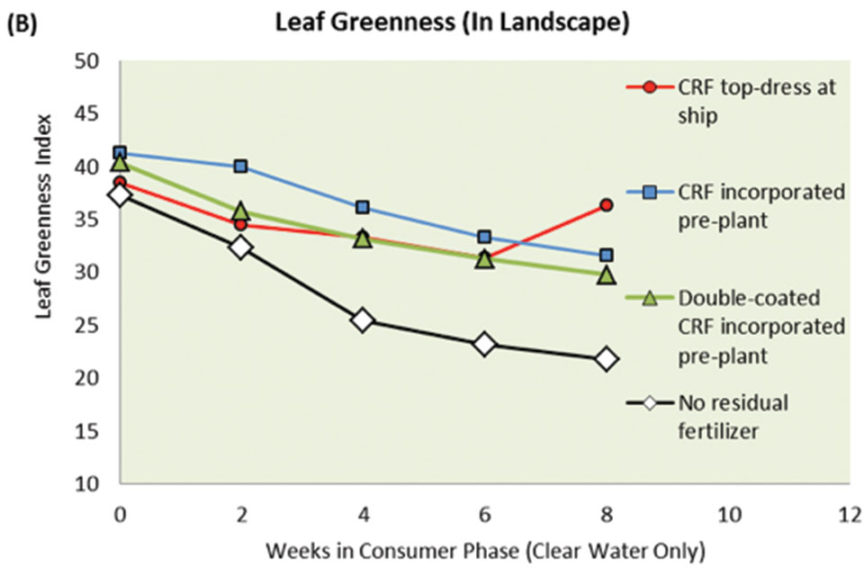

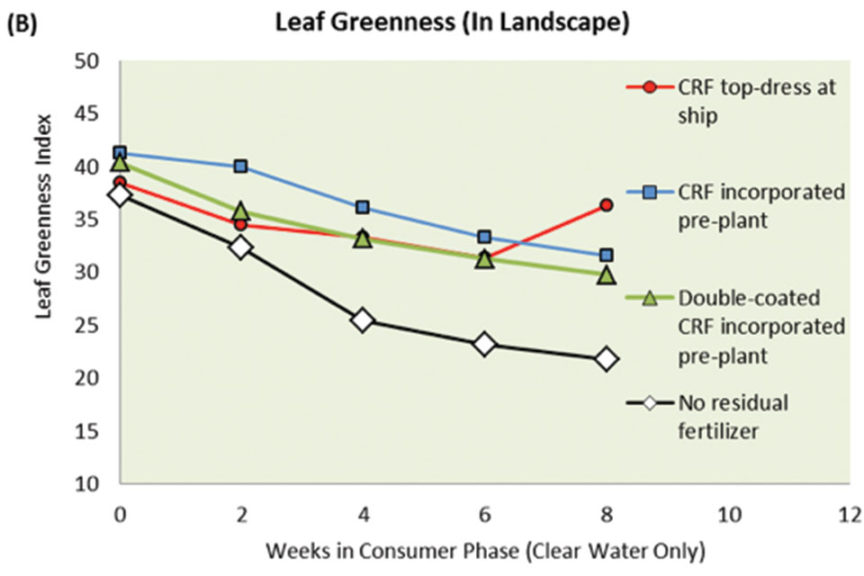

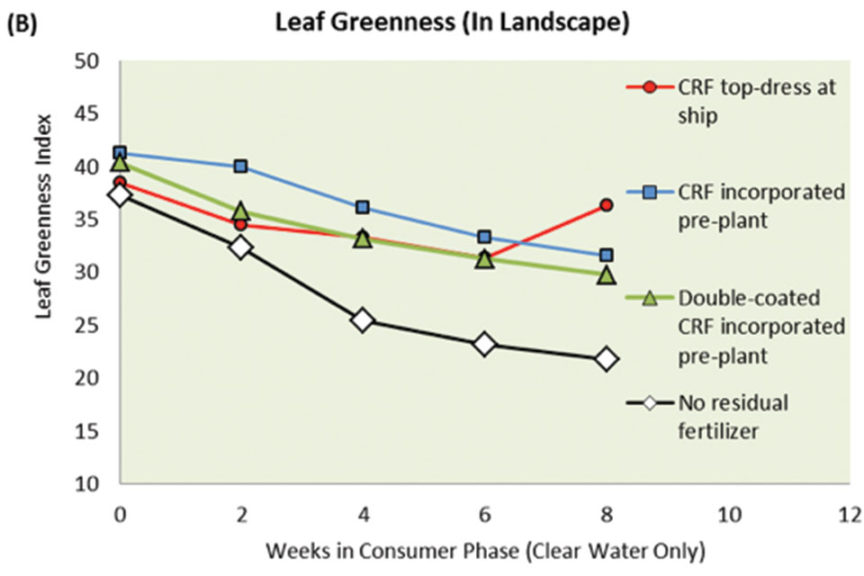

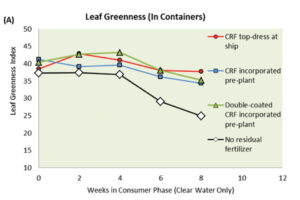

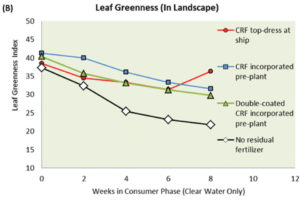

During the consumer phase in our trial, all plants were irrigated with clear water. Plants either remained in the 1-gallon containers, or were planted in the landscape in a Florida sandy soil, during November through January. Results during the consumer phase are shown in Figures 2 and 3. All strategies that provided residual fertilizer improved consumer performance (leaf greenness and flower number) compared with WSF only.

Some attributes of different fertilizer strategies included:

1. Our “control” of WSF at 200 ppm N during production and no additional residual fertilizer for the consumer. This strategy had the lowest production cost ($0.020 per 1-gallon container) but had the poorest plant performance.

2. Producing with WSF followed by top-dressing with a CRF immediately before the consumer phase (simulated point of shipping). This strategy has low risk for the grower, without challenges such as “flashing” (rapid nutrient release of CRF, especially from stored growing medium) or mixing errors. However, there is added labor at shipping, and fertilizer may fall out unless a glue-type or tablet CRF is used. Cost was $0.084, which included the WSF during production, labor to top-dress, plus CRF at 10 lbs/cubic yard equivalent.

3. Incorporating CRF into the growing substrate before planting, where the CRF had a longer release period (five to six months) than the production phase and plants only received clear water during both the production and consumer phases. This strategy had no additional labor and did not require a fertilizer injector during production. Fertilizer cost equaled $0.051 per container at 10 lbs CRF per cubic yard.

4. A double-coated CRF that was incorporated before planting, but only began to release nutrients during the consumer phase. This approach allowed us to use WSF at 200 ppm N during production, without release of the CRF until the consumer phase began. Because the CRF was incorporated before planting, there was no labor or spillage problems associated with top-dressing. Cost was $0.085 at 10 lbs/cubic yard.

Main Findings

• All fertilizer strategies tested produced horticulturally acceptable plants after six weeks in the production phase.

• Plant performance was greater during the consumer phase in treatments with high rates (10 lbs/cubic yard) of incorporated or top-dressed CRF compared with either WSF only, or lower rates of CRF.

• The nutrient release, in a separate trial at 50°F, 70°F, or 90°F, was delayed by double-coated CRF compared with single-coated CRF, and this release rate was temperature-dependent (from 50 to 30 days as temperature increased).

• A partial budget found that the lowest cost treatment was WSF, and adding high rates of residual fertilizer using either single- or double-coated CRF added an additional 3 to 5 cents per container.

Take-Home Message

No matter how good the genetics are, we are not selling beauty or ensuring consumer success if plants turn yellow, wither, and die after sale. Selling potted plants that rapidly decline is not a sustainable strategy for repeat sales.

Consider providing residual slow-release fertilizer for the consumer, in order to add value and differentiate product quality. Many consumers are unlikely to fertilize plants after sale. Without residual fertilizer, plants may never achieve their potential landscape or potted plant performance. All the strategies we evaluated to add residual fertilizer improved consumer performance — choose the best fit for your operation in terms of cost, labor, risk, and the potential for increased sales price or return sales.

Paul Fisher ([email protected]) is a Professor and Extension Specialist at the University of Florida, Sueyde F. de Oliveira is Research and Development Coordinator, Ginegar, Brazil, and Simone da C. Mello is a Professor in the Crop Science Department, University of Sao Paulo, Brazil. The authors are grateful for funding from their partners in the Floriculture Research Alliance, the NIFA Floriculture Nursery and Research Initiative, and CAPES. Supplies were provided by Innovaplant Costa Rica, Blackmore Co., ICL, and Sun Gro Horticulture. For more information on the study, see the publication in HortTechnology 2016 26:164-175. Contact Dr. Fred Hulme, for more details about double-coated CRF. Tradenames are included for clarity, and no endorsement is implied by the authors or their institutions.