On The Cutting Edge

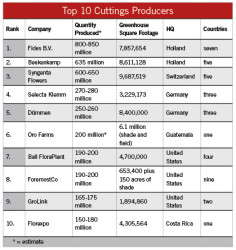

While cuttings farms in Latin America tend to serve the United States and Canada, farms in Africa serve Europe. One company that has been expanding aggressively in both hemispheres is Dömmen, which just built a 50-acre facility in El Salvador and is adding 20 more acres to its farm in Ethiopia.

Selecta recently built a super elite (SEE) production facility for nuclear stock and has reorganized which crops are produced at each facility. “We have three production centers with specialized crops assigned to each site and a state-of-the-art SEE production facility,” owner Nils Klemm says. “We can see that both our cost per cutting and quality have been affected positively by this reorganization.”

Growth Drivers

What is fueling the demand for more cuttings production? Vegetative annuals, perennials and herbs. The hottest trend is rooting several cuttings into a single liner to create instant combination plantings. (See page 6.) Growers have the option of doing the rooting themselves or buying in liners from rooting specialists.

The dominant multi liner program with an aggressive, first-mover advantage is Confetti from Dömmen. Selecta is offering Trixi liners through Ball Seed and Syngenta has Kwik Kombos. Beyond extensive trialing to see which plants will grow well together, a crucial factor to making these programs work is for cuttings to be delivered together, ready to stick and assemble. Selecta has packaging and labeling to identify Trixi shipments. Dömmen Confettis are presorted, color coded and arrive together in a box.

Dömmen’s Chief Business Development Officer Perry Wismans emphasizes the delivery guarantee that comes with Confettis. “This means that when a Confetti is delayed or incomplete at delivery, the affected product is free of charge,” he says. “With this guarantee, Dömmen shows it understands the importance of receiving inputs in time to allow for successful mixed container production.”

Alternative Combo Strategies

Cuttings producers who are not directly involved in multi liner programs are still looking for ways to help growers produce effective combination plantings.

Ball FloraPlant has developed a method that takes very young liners and plants them as a group into finished containers. “This achieves the same look as a multi-stuck liner but allows the varieties to be treated individually while in propagation, therefore providing great potentials for combinations and grower advantages,” says Ball FloraPlant’s General Manager Allan Davidson. “We are providing sun and shade combinations and the flexibility for growers to produce them from unrooted cuttings or liners.”

Ecke Ranch has made it easier for growers to order and schedule combination programs, COO Steve Rinehart says. “For the first time, Ecke systems are referring to combinations by name and allowing a grower or broker to order by retail week. Ecke systems are built to source combination components and assure delivery of all needed varieties. In addition, this year cuttings can be sourced as either rooted or unrooted.”

Rooting Right

Dömmen has developed a rooting medium, Aero NT, produced by Omni Growing Solutions in St. Catharines, Ontario. All rooted products sold by Dömmen USA will be rooted in this system. The stable substrate promotes air circulation which results in reduced disease and a higher rooting rate that’s 25 percent faster, according to Omni Growing Solutions.

Ball FloraPlant’s Genesis cutting is a significant improvement on the existing callused product form, Davidson says. “We are offering this in both our geranium and osteospermum product lines. This new form allows growers to be more successful in direct sticking these crops, providing both significant savings in labor and crop time, as well as producing a better quality product,” he says. “Growers who wish to use this form in producing liners can cut their rooting time in half, eliminate losses and ultimately reduce rooting costs.

“We must reliably deliver top quality cuttings at competitive pricing. This, combined with introducing innovative new products and programs, gives a grower an overall value package that continues to make us successful.”