Save Water With Automation And Sensors

Automating irrigation is a great way to save water. One of the latest innovations in irrigation automation is the use of substrate moisture sensors to trigger irrigation. These sensors are relatively inexpensive and, when used, can conserve water and, consequently, reduce pollution and the amount of money spent on electricity for pumps in wells. A wide variety of annual and perennial plants may be irrigated with as little as 0.3 to 1.3 gallons of water for the entire cropping cycle using substrate moisture sensors.

Sensors Ensure Proper Substrate Moisture For High-Quality Plants

Most substrate moisture sensors literally measure the amount of water in soils. This is usually expressed by volume, as the ratio of the volume of water to the volume of substrate in a pot (substrate moisture content percent = (volume of water xvolume of substrate) / 100).

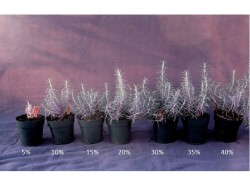

In peat-based substrates, the substrate moisture content of 45 to 50 percent is near container capacity. Rosemary plants grown at 5 percent moisture content in a peat-and-perlite substrate are dead, while those at 30 percent or greater are high-quality, large plants (see photo above).

Sensors may be used in a wide variety of substrates (peat-based mixtures, rockwool, perlite). However, the percentage of moisture applied may vary depending on the substrate you use. If the rosemary had been grown in a well-drained substrate with bark, the substrate would drain much more quickly and the percentages needed to maintain high-quality plants may be higher. If you are using moisture sensors in your own custom mix, consider trying different moisture contents on a small number of plants to determine the correct set point for your irrigation system.

New Moisture Sensors Measure Irrigation And Fertigation

There are many sensors available for growers, and they vary in cost and reliability. Some moisture sensors are sensitive to electrical conductivity and temperature, so it is important to select a sensor that provides reliable measurements when the environmental conditions within your greenhouse are normal.

A common type of sensor consists of two electrodes separated by a material called a dielectric. Greenhouse potting media or substrates are dielectric, a property that is highly dependent on the moisture content. These sensors have a fast response time with short probes for measuring pot moisture and are relatively inexpensive.

The sensors vary in size from 4 inches (EC-10) to 2 inches (EC-5), so they are small enough to fit in a 4-inch pot, but not a plug tray. While these sensors are useable within a wide range of electrical conductivities, topdressing or dibbling very close to the sensor causes faulty measurements. Using liquid feed or incorporating slow release or dibbling fertilizers away from sensors will provide better results. New sensors measure substrate moisture, electrical conductivity and temperature. These sensors provide growers with the possibility of integrating irrigation and fertigation measurement and automation.

Integrating Sensors Into A Greenhouse Irrigation System

Moisture sensors are primarily used to automate irrigation in drip irrigation systems but have also been used in capillary mat systems. For drip irrigation, sensors are inserted so that they are vertical at a 45-degree angle in the pot. Since the sensors take the average measurements along the length of the sensor, inserting them vertically ensures that you are measuring in the root zone.

Many growers are concerned about spatial variation in greenhouses – how many sensors do you need to automate a bench? What about a greenhouse? If you have one sensor automating an entire bench, variations in light along the bench may cause some plants to dry out faster than other plants. This is something to keep in mind when designing a system. When designing a drip system with sensors, it is advisable to group plants according to size. Sensors used to automate irrigation should be placed on the bench in spots you anticipate drying out first – this could be the largest plants or corners and edges. Plants that will dry out more slowly (small plants or those in the center of the bench) could contain sensors for monitoring to prevent excessive irrigation or disease problems. Using sensor-automated irrigation actually prevents pathogens and associated economic costs.

At the University of Nebraska-Lincoln, capacitance moisture sensors have been used as part of an automated irrigation system using a capillary mat system for greenhouse strawberry production. This system is a spatial-bottom watering system that depends on capillary action to move water and fertilizer from a saturated mat to the roots in a pot. Once the capillary column is established, pots on the mat cannot be moved. Therefore, it is important that the grower know that his irrigation system is working correctly and that his potted plants are receiving the correct amounts of water and fertilizer. Some variance in pot moisture and fertilizer is always to be expected, so measuring selected pots in key spatial locations of the mat will inform growers that the system is providing sufficient moisture.

In the Nebraska study, researchers selected six sensor locations for pots on the mat, including a southern location near the emitter manifold, the middle of the mat and the north end of the mat. The middle of the mat was most crucial because this was the location in the greenhouse that received the most sunlight during the day.

Pot moisture and electrical conductivity can be spot-checked daily with a capacitance sensor and a hand-held meter or monitored more frequently when using a data logger system with sensors kept in a pot. Spot checking should be done during the sunny periods when plant water use is expected to be the greatest. Plants must be visually inspected on a daily basis, as inspections are a key indicator of irrigation performance.

Substrate moisture sensors are a great way to reduce pathogens and water waste and save money when you are automating irrigation in your greenhouse. Sensors may be used in drip irrigation or capillary mat systems, and it is likely that in the future, they may be used to automate other sustainable irrigation systems such as sub-irrigation, as well.