Golden State Bulb Growers Increases Efficiency With New Calla Bulb Grading Line

Necessity is the mother of invention, and that’s certainly true for Golden State Bulb Growers. The Moss Landing, Calif., operation, which supplies its Callafornia Calla Lily bulbs to wholesale markets around the world, was in need of a more streamlined and less labor-intensive solution to grade and sort bulbs.

So Golden State’s management team got creative and started talking with MAF Industries, part of the MAF-RODA Group that specializes in the design and manufacture of grading, packing, palletizing and handling fresh fruit and vegetable systems. The manufacturer was willing to work with Golden State on the Calla Lily bulb grading and sorting machine design process.

This resulted in Golden State Bulb Growers investing $700,000 to purchase the new grading system to better serve the needs of its customers, increasing uniformity and productivity in its Callafornia Callas bulb processing.

Investing in the new system has also allowed Golden State Bulb Growers to eliminate its second shift during the peak season, which is particularly beneficial, in light of continually rising labor costs and shortages.

[blackoutgallery id=”76757″]

Golden State’s System Is Customized For Callas

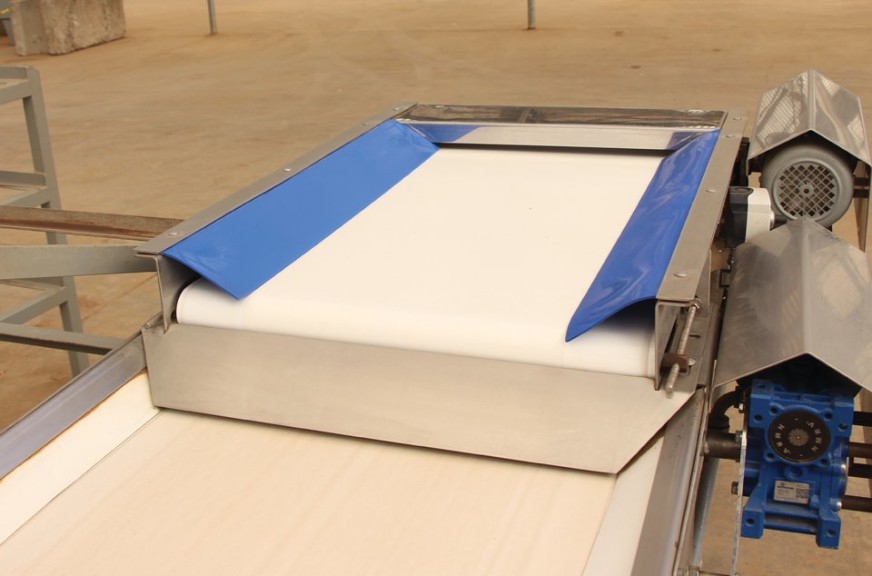

Typically used to grade and sort cucumbers, peppers and other vegetables, the MAF grader needed a few tweaks, including special pads, belts and flaps, to make it gentle enough to handle fragile Calla tubers, and prevent any potential damage, Ferguson says.

The system uses advanced camera and software technology to determine the size of each tuber and deliver tubers to trays for storage and shipping. The design includes modified deliveries and transition points, use of specialized materials and unique software programming. These features work together to ensure highly accurate sizing, without jeopardizing cosmetic quality.

All sections of the machine operate with variable speed drives, allowing maximum flexibility in staffing of the system and flow of product. Currently, Golden State Bulb Growers is working to tweak the stages of belts to maximize efficiency and productivity.

“Automation often runs the risk of tying workers to a limited set of options,” Ferguson says. “But the flexibility of variable speeds allows the operation to run more effectively.”

The machine also has the ability to adjust to tubers with variable quality characteristics.

How The System Works

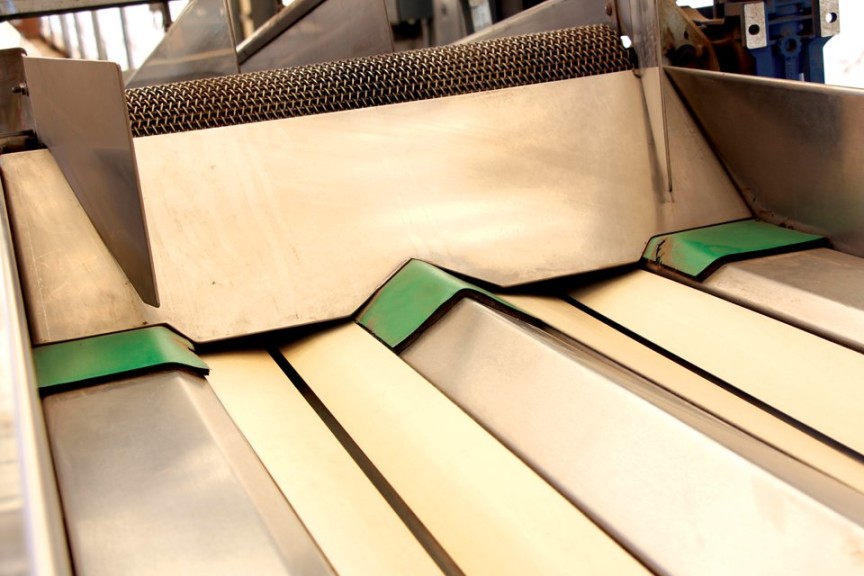

Golden State placed conveyor belts in the staffing area that allow workers at each station to clean raw tubers that are still dirty from the field, placing the good tubers on the conveyor belt. Each worker has accountability for his or her own area, which drives improvement and productivity, Ferguson says.

From there, tubers move onto the input belt, where workers continue to select for quality, and then pass through a computer that features a camera box, which selects tubers by size and shape.

The regrade process separates bulbs out into smaller orders and is able to process two colors of Callas at once. The primary grade accommodates all sizes and batch counts bulbs into trays. The machine provides flexibility by carrying out two different functions at once.

In the camera box, a light outlines the tuber to measure size, and drop counts all tubers, which saves growers time and tedium. Tubers are moved through the camera box into the packing area, and then automatically separated out and filled into trays with the required count number. Workers then spread out the bulbs onto the trays for storage or shipping.

An overhead conveyor moves clean trays from one end of the production line, where workers are emptying tubers to be graded, to the other, where workers are packing the cleaned, graded and processed tubers. Workers wear helmets and safety goggles to protect them from any potential falling trays.

Check out a video of Golden State Bulb Growers’ new Callafornia Callas bulb grading and sorting system.

Improved Efficiency Reduces Labor And Repetition

Golden State Bulb Growers is a 104-year-old company, and before the new automated process, the antiquated sorting, sizing and counting process dated back to its origin, which was labor-intensive and not as productive.

Workers cleaned bulbs and sized each bulb against a sizing board at tables within the packing area. All quality control, sizing and counting relied on human subjectivity and was subject to human error.

Whereas now, while the machine reduces labor by automating sizing and counting, the process still requires the discerning human eye to judge tuber quality, Ferguson says. Perhaps eventually, quality control could be automated, as well.

With the computer and machinery, all tubers are sized and placed into trays. This allows workers to focus on quality, cleanliness and packaging.

Since the operation started using the new process, productivity has more than tripled. Workers who were cleaning and processing 300 tubers per hour are now able to process 1,000 tubers per hour. The operation also benefits from keeping more skilled labor and relying less on unskilled workers to crank production.

“Significant increases in quality and productivity have been achieved by using the new grading system,” Ferguson says. “This has allowed the operation to effectively keep costs in line, despite continually rising labor costs and shortages, with the ultimate goal of providing the best value to our grower customers.”

The grading system was designed to efficiently handle the quality inspection and resizing of product that happens later in the season. Golden State Bulb Growers is currently working on fine-tuning the system to handle the other seasonal crops it produces, like its AmeriHybrid Begonias, Aloha Lily Eucomis and Caribbean Jewels Scilla.

Get To Know Golden State Bulb Growers

A fifth generation family firm, Golden State Bulb Growers has been producing flower bulbs since 1911. Its primary products are Callafornia Callas, AmeriHybrid Begonias, Aloha Lily Eucomis and Caribbean Jewels Scilla.

Golden State Bulb Growers is a vertically integrated firm that controls all aspects of production from breeding to the commercial introduction of new varieties. It is the world’s largest producer of both tuberous Begonias and colored Callas.

The operation houses nearly all of its related research, allowing it to continue to be on the leading edge of methods and technology for its products. It takes 10 years to introduce a new variety of Callafornia Callas and this is achieved by a well-educated, international staff that’s committed to a vision of quality.