High Tunnels Help To Expand Markets, Crops

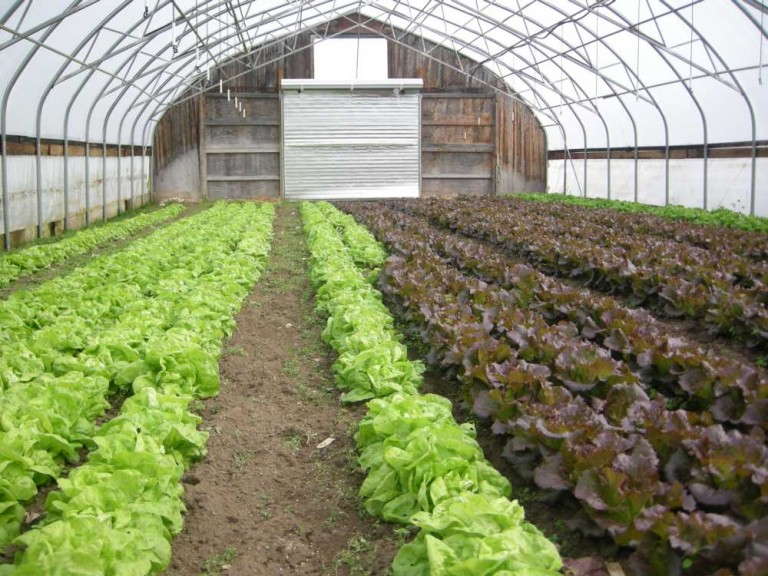

USDA’s Natural Resources Conservation Service (NRCS) first offered grants for seasonal high tunnels as a conservation practice in fiscal year 2010. The Environmental Quality Incentives Program (EQIP) Seasonal High Tunnel Initiative is part of a three-year trial to determine the effectiveness of high tunnels to assist growers in extending the production season for high value crops in an environmentally safe manner.

During its first year, NRCS received nearly 3,000 applications for seasonal high tunnels. The agency allocated $13 million in fiscal year 2010 for 2,422 seasonal high tunnels in 43 states.

[blackoutgallery id=”58954″]

Growers Get On Board

During the first year of the high tunnel initiative, Arkansas obligated $57,129 for 14 high tunnels. Since the program started, University of Arkansas professor and fruit Extension specialist Elena Garcia said the number of high tunnels in use in the state has grown exponentially.

“Three years ago I sent out an email asking growers how many high tunnels they were using,” Garcia says. “Many of the responses that came back asked ‘What is a high tunnel?’ Today, most growers know what a high tunnel is and many of them are using them due in large part to the work of our state’s Extension agents.”

Garcia says more vegetable growers are using high tunnels, followed by ornamental and fruit growers.

“Those growers who are selling to farmers markets have really taken advantage of the NRCS program,” she says. “Tomatoes, cucumbers and greens are the most common vegetable crops. Most of the flowers being grown are fresh cut. Fruit growers have been more hesitant to try high tunnels because of the high management practices of their crops.”

Garcia says in addition to farmers markets, other outlets include local restaurants, organic co-ops and pick-your-own operations. Most growers have been able to make more money for their crops selling in niche markets.

Grower And Crop Diversification

Cornell Cooperative Extension vegetable specialist Judson Reid says the New York growers who initially started using high tunnels were primarily direct marketers.

“These were farmers who sold their crops at roadside stands, in their own on-farm stores or at farmers markets,” Reid says. “They were receiving retail prices for their crops and the return was very good. Those growers were usually small- to medium-size operations.”

Reid says more medium- to large-size growers have started to use tunnels to increase their outputs to larger markets, including supermarkets.

“The larger growers want to improve quality to compete with the fresh market tomatoes coming from Canadian and Mexican greenhouses,” he says. “The U.S. field grower needs to have a quality product that competes with these imported tomatoes, and high tunnel tomatoes can do that. The high tunnels are being used primarily by field vegetable growers who want to extend the season and improve disease control, quality and/or yield.”

Reid says he has also worked with ornamental plant growers who have produced a spring bedding plant crop that is sold out shortly after Mother’s Day.

“These flower growers realize they have production space available for a few months and some will put in tomatoes in grow bags or some other substrate,” he says. “But most of the traditional growers using high tunnels are growing in the soil. The appeal to vegetable growers is they don’t have to learn how to grow a crop in pots or hydroponically with high tunnels. However, growers who are using a substrate for ornamentals usually put their high tunnel crops in grow bags or some other substrate, as their floors are not tillable.”

Reid says it is possible for ornamental growers to combine hanging baskets with vegetable crops.

“We did a study looking at the feasibility of growing a crop of petunia hanging baskets over the top of a crop of tomatoes in a high tunnel,” he says. “Petunias are a good crop because they can take low temperatures. The cooler temperature in the high tunnel tends to increase the branching or shorten the internode length on the petunias,resulting in very sturdy plants.”

Most high tunnel vegetable growers are producing tomatoes because they bring the best prices, Reid says. Another popular vegetable crop is Beit Alpha cucumber, which is a small, thin-skinned, seedless cucumber that grows well in high tunnels and produces high yields.

The high tunnels are also being used during the winter with no or minimum heat to produce a variety of greens, including Swiss chard, spinach and arugula, Reid says.

Developing New Crops, Cultivars

While most of the vegetables being grown in high tunnels are common greenhouse and field crops, research is being done to develop new crops and cultivars that will do well in these structures.

One of the promising crops that Garcia says she has seen good results with is table grapes.

“We trialed several grape cultivars inside and outside the tunnels,” Garcia says. “Normally, it takes two to three years outdoors before there is any fruit production. We had fruit production on the high tunnel plants the year after they were planted.”

The biggest surprise with the high tunnel grapes came during the second year when some plants were producing up to 80 pounds of fruit.

“Normally for outdoor grapes, the yield would be 30 to 40 pounds per plant during the third year,” Garcia says. “The higher yields on the high tunnel plants came during the second year. The yields were phenomenal.”

Another advantage Garcia saw with the high tunnel grapes was the reduction in fungicide applications.

“Depending on the weather, Arkansas growers usually have to spray field grapes six to eight times per year to control black rot and other fungal diseases,” she says. “We only had to spray twice with the high tunnel grapes.”

Garcia has received additional funding and is planning to expand her research with high tunnel grapes.

Garcia and commercial strawberry growers have found that some cultivars don’t do as well in high tunnels as they do in the field.

She says ‘Festival’ has proven to be the workhorse for high tunnel production. The cultivar has been found to be less prone to disease and insect problems.

The cultivar ‘Albion,’ which she says is well-liked and has good taste, is a magnet for spider mites when grown in high tunnels.

“Spider mites absolutely love ‘Albion,’” she says. “Outside, ‘Albion’ doesn’t have issues with mites. In high tunnels, it is difficult to grow without having to make numerous miticide applications. We have had to do quite of bit of screening work to determine which cultivars would do better in the tunnels.”

High Tunnel Evolution

A high tunnel is a very natural progression toward a greenhouse, Reid says.

“A high tunnel is a greenhouse, it’s simply a low technology greenhouse,” he says. “There are all these gradations between a high tunnel and a fully automated greenhouse.”

One of the biggest issues with high tunnels is using a single layer of polyethylene film.

“If growers are going to take a step up in technology, the first thing I suggest is they install an inflated layer of plastic,” Reid says. “Starting plants in high tunnels in April can be an issue because of late frosts. If there is only a single layer of plastic, it’s difficult to prevent cold or frost damage.”

“If a grower adds electricity for poly-film inflation, the next piece of automation growers should consider is a thermostatically controlled exhaust fan to bring in fresh air, which will raise carbon dioxide levels and lower relative humidity levels.”

Most of the high tunnels being used by growers come equipped with roll-up sides for ventilation, Reid says.

“High tunnels help to greatly reduce the incidence of common field-grown tomato diseases like early blight and bacterial leaf spot,” he says. “However, since the environment in the high tunnel is hot and dry, we do see typical greenhouses pests that don’t occur in the field, like more western flower thrips and two-spotted spider mites.”

Most growers who install an irrigation system use a drip system. Reid recommended that growers also add some type of fertilizer injector system.

For more information, contact M. Elena Garcia, University of Arkansas, Department of Horticulture at 479-575-2790 or [email protected]; Judson Reid, Cornell Cooperative Extension at 315-536-5123; or [email protected]; or visit http://www.hort.cornell.edu/hightunnel.