The Future Of Greenhouse Structures

Photo courtesy of Jeff Warschauer

The iconic image of our industry — the greenhouse itself — is changing. What it is and where you’ll find it may be very different by 2043.

Stop and think about all of the advances in greenhouse technology in the last three decades. Today’s structures would certainly be recognizable as a greenhouse to yesterday’s growers. But capabilities of these facilities to efficiently produce high-quality plants are a world away from many of those older structures. The pace of those changes will increase in the next 30 years.

We’re not predicting the end of the Quonset or big gutter-connect ranges. We do, however, believe you will see a dramatic change in the ways some traditional structures work, where greenhouses are built, or even what is considered a “greenhouse” in the future.

Food And “Local” Will Bring Greenhouses To Where The People Are

“Food will play a big part in driving the future in greenhouse designs. Developments for ornamental horticulture will still be driven by naturally ventilated concepts, but if you look at where the greenhouse industry is going, I think food is going to drive the technology with sealed and fully controlled environments.

“Whole Foods and Gotham Greens 2 are currently building 20,000-square-foot greenhouses on top of Whole Foods’ newest New York City supermarket. If this works, I think other supermarkets will follow suit.

“Gotham Greens 1 has already been supplying Whole Foods stores with ultra-fresh produce. A sign in the produce department states, ‘Locally Grown by Gotham Greens 1, 2.5 miles away.’ The new Whole Foods sign might read, ‘Locally grown by Gotham Greens 2 upstairs.’ Can it be any fresher than that?”

— Jeff Warschauer Vice President of Sales, Nexus Corporation

Innovative Open-Roof Structures

“Naturally ventilated greenhouses are still the future for most propagation, finish and prefinished ornamental growers, but I want to see a new type of open roof for the greenhouse industry in the next 5, 10 or 20 years. The conventional open roof as you and I know it today are multi-, mini roofs and have large roof vent panels that stand straight up. These panels cut a portion of light, reduce air movement within the interior environment and have many more gutters then conventional wide-span houses.

“The improvement will be a new structure design for opening the roof and an improved covering. Similar to what we now know as the peak open-roof cloth system but would be improved using new long-life textiles, plastics or a hard covering that can roll, push, pull, fold or accordion, or maybe you’ll just push a button and – poof! – it turns to dust. I don’t know. But whatever crazy idea it is, it will be the single biggest avenue for new greenhouse design for ornamental growers.”

— Jeff Warschauer Vice President of Sales, Nexus Corporation

Growing Without Natural Light

Is the future of the greenhouse even a greenhouse at all? Advances in lighting technology will make It possible to produce plants in warehouses or other completely enclosed buildings with no source of natural light.

“Closed environment growing with narrow spectrum light is coming. It will start with the simple stuff, things like lettuce and microgreens that are vegetative and just need a simple spectrum for photosynthesis. Things that are more complicated — plants that require flowering or fruit set — are going to take some systematic research to find out what’s required there.

“Where solar light is abundant it should be leveraged for crop growth. However, within 10 years there will be significant integration of LED sources into all kinds of horticultural growing, including closed spaces. I call this sole-source lighting. It’s happening with fluorescents already. As LED costs go down and efficiencies go up it will be more compelling. It’s not going to happen overnight, but you’ll see differences in five years. In 10 years it will be massive. And in 30 years we’ll probably have moved beyond LED to something completely different.

“We’re on the cusp of a lighting revolution.”

— Dr. Cary Mitchell Professor of Plant Physiology Purdue University

Photo courtesy of Plantagon

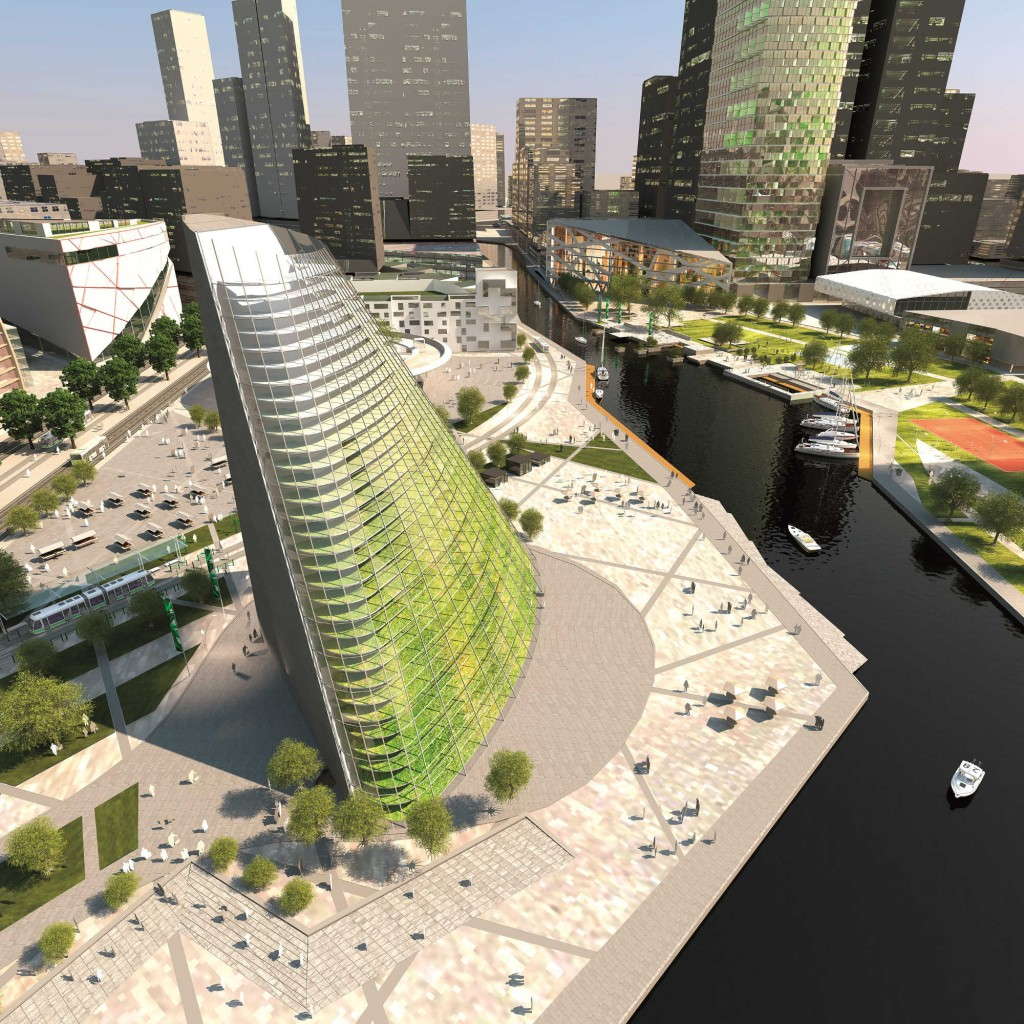

Urban Structures Offer Vertical Farming Solutions

We’re a little more than 30 years away from the Earth’s population reaching 9 billion people, which means more urban sprawl, less available land and an extra 2 billion mouths to feed. With greenhouses already making their appearances on city rooftops and lighting technology advancing by leaps and bounds, perhaps the next step is building up instead of out.

Swedish-American company Plantagon has drafted a solution for building a high-rise model for urban agriculture. The helix-shaped greenhouse offers the possibility for clean and sustainable food production in urban areas. In addition to standalone greenhouses, Plantagon creates commercial buildings, such as offices and hotels, with functional greenhouse area built into the facade. Growing area can also be retrofitted onto existing high-rise buildings. The structures provide the buildings with shade, but let through enough sunlight for office activity.

By expanding the greenhouse vertically, Plantagon claims its patented technology will increase the amount of crops produced considerably compared to the land area used, permitting multiple harvests for the same growth period.

”Urban agriculture is exciting and challenging in many ways,” says Eva Nygren, CEO of Sweco Sweden, Plantagon’s partner company. “The Plantagon greenhouse has attracted a lot of attention all over the world, and we believe that the new generation of greenhouses — combining a sustainable building with function and great design — will be even more attractive to cities.”

Could Grow-Your-Own Circumvent Traditional Growers?

A Canadian-based company, Urban Cultivator, is helping homeowners and restaurants take growing their own fresh produce to the next level, with a unit that grows up to 50 types of microgreens and vegetables on-site. The company says its units could be as common in home kitchens within five years as a dishwasher. Just three years after developing the Urban Cultivator, which offers models for residential and commercial use, the company has buy-in from some of the largest hotel chains (Four Seasons, Fairmont) and food corporations (Aramark, Cisco) in North America. Residential developers are using the units as green marketing to set the value of their condos and homes apart in the rough economy.

“Fresh cut greens have double the nutritional value of precut within 24 hours,” says Tarren Wolfe, the co-founder of Urban Cultivator. “So this is a way for everyone to be self sufficient, while cutting down on the food-travel carbon footprint in a big way. You’re connecting people to their food, educating them, allowing them to deliver a healthier, better product to themselves or their consumer. Look at how much money we spend policing the term ‘organic.’ If everyone is able to grow produce and be self-sufficient, think about how much money we would save. Same with healthcare costs, especially in the U.S. It’s a reciprocal product. Whomever buys these — whatever homeowner, whatever restaurant — they want to tell everybody about it.”

The cost for a residential unit is $2,200. Wolfe says some people have sticker shock initially but when you break down the cost, it ends up being a two-year return on investment, based on the average consumer spending over $100/month in greens. “This way you can do it year-round, and you know it’s clean because you grew it,” he says.

Commercial units cost $8,000 total, but restaurants can lease a commercial unit for $250 per month on a five-year lease-to-own program, Wolfe says. “That’s very cost-effective for high-end restaurants like Four Seasons, which can spend thousands per month buying microgreens from greenhouses.”