Boom Technology Helps Irrigate Multiple Crops at Foertmeyer & Sons

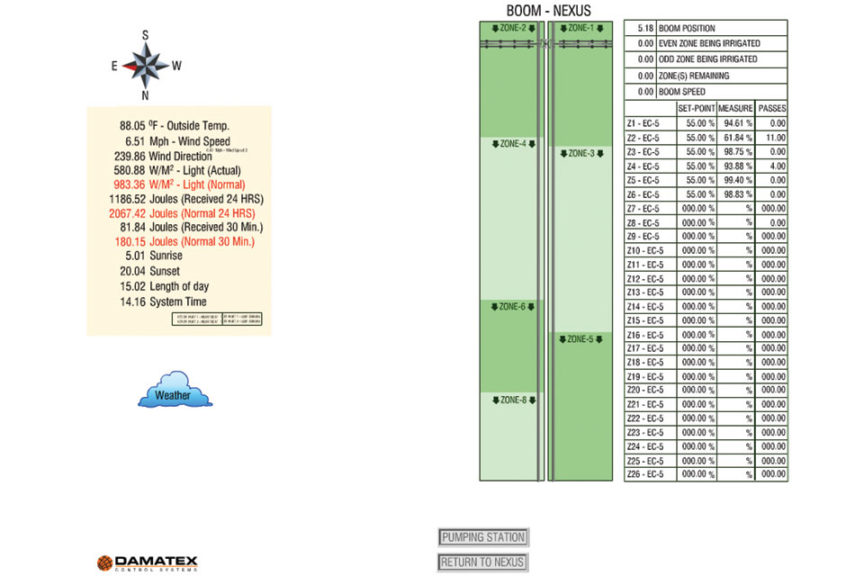

Over the past few years, Foertmeyer & Sons in Delaware, OH, has been using boom technology in its greenhouses. The boom system in place is a collaboration between Damatex Control Systems and Visser NA, with Damatex providing the controls for the booms and Visser manufacturing the actual boom hardware.

“I approached Damatex a few years back with some ideas and desires for how I’d like my booms to be controlled,” says Matt Foertmeyer, Head Grower at Foertmeyer & Sons. “After talking with several boom manufacturing companies about what was available on the market, we came to the conclusion that Damatex should build a control system from the ground up for us, and our facility would serve as a beta test for the new system.”

The booms incorporate several different technologies into one single setup.

“I’ve been a big fan of Decagon EC5 soil moisture sensors for many years, and what I wanted was a boom that could be controlled by these sensors,” Foertmeyer says. “With these booms, I’m able to program individual zones for each separate crop in my bays, and then assign a separate EC5 soil moisture sensor to control the irrigation of these separate zones.”

The greenhouses at Foertmeyer & Sons often have many different crops in a given bay all with different irrigation needs, and the booms offer flexibility in how to grow and irrigate the separate crops.

“With the soil moisture sensors, I can set a crop of verbena to be grown more dry than a crop of calibrachoa in the same bay, and once a plant dries down to its given set point, the boom then automatically kicks on and irrigates that crop,” Foertmeyer says. “The zones can be any size I want them to be, and I can set as many as I want in a given bay.”

Damatex has developed stand-alone controllers for each boom that offer most of the functionality Foertmeyer was looking for, and he can also tie the booms into their overall environmental control system for complete control.

“Because the controllers are stand-alone they can be installed onto an existing boom already installed in a greenhouse,” Foertmeyer says. “However, for new systems, they are working closely with Visser NA in providing the complete package.”

Foertmeyer will discuss the implementation of this boom technology in greater detail at AmericanHort’s Production Technology Conference in October.

Also on Tap at the Production Technology Conference

• Benefits of Adding Technology Into Your Business Including Nandina Liners, Spacing Robots, and Drones — Neil Marek of Magnolia Gardens Nursery in Magnolia, TX, will go through several of the innovations Magnolia Gardens Nursery has adopted over the past couple years, and how they have helped improve production and labor efficiency.

• Automation and How it Works for Hoffman Nursery — How do you grow your business while facing a huge labor shortage? Hoffman Nursery is solving the dilemma by using technology and working with suppliers like AgriNomix to incorporate automation and build more efficient processes. Learn about its solutions — from automating transplanting to eliminating production bottlenecks — to find ways you can produce high-quality plants more profitably.

• Technology at Metrolina Greenhouses — Art VanWingerden, Co-Owner and co-CEO of Metrolina, will discuss how technology such as sticking machines and spacing robots has helped Metrolina reduce labor costs.

• Water Retention at Metrolina’s York Facility — VanWingerden will also lead this discussion.