Emerald Coast Growers Steps-Up Production Efficiency And Broadens Its Phlox Program

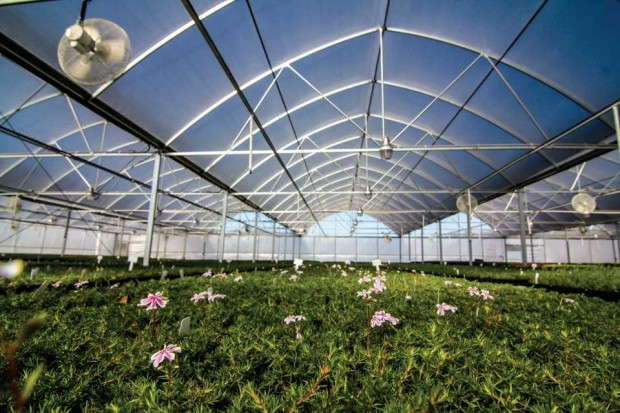

The new gutter connect Atlas Greenhouse at Emerald Coast Growers will allow for a shift in its phlox production.

Emerald Coast Growers, a supplier of perennial starter plants and ornamental grass liners, is not averse to expansion projects. In 2010, it celebrated its 20th anniversary with an expansion of its perennial production space. More recently, the company has been in a nearly continuous phase of construction and improvement projects.

Its newest addition of 21,504 square feet of production space at its Pensacola, Fla., headquarters follows 2014 projects that include a 25,344-square-foot facility in Milton, Fla., for ornamental grass production and a consolidated soil-mixing facility, not to mention an expanded in-house shipping facility in 2013. All total, the Pensacola project brings Emerald Coast to more than 450,000 square feet under cover, plus 25 acres of field production, and allows the company to refocus and expand its perennial contributions.

“We are always looking for ways to increase our plant offerings while looking to improve plant quality,” says Josiah Raymer, head grower at Emerald Coast Growers. “An increase in demand made the expansion the right decision for us.”

The new greenhouse is part of Emerald Coast’s master plan to ramp up its popular 128 size, which is in high demand, and expand its phlox program. It accommodates a shift in Phlox subulata production and frees up space for the inclusion of new crops at its Pace, Fla., location. Raymer says the new facility has already resulted in an increase in overall volume, as well as improved production efficiency.

The new facility is a gutter-connect Atlas greenhouse with a double-inflated poly top, 40 percent shade cloth and roll-up sidewalls for natural ventilation. It holds 9,600 trays of phlox and heuchera. A Microgrow Ventmate Plus control system, specially designed for use with ventilation-cooled structures, operates the sidewalls and regulates day and night temperatures and air circulation. HPS lighting is used for day length control. For irrigation, a Senniger mini-wobbler overhead system offers uniform coverage and large-diameter application at low pressures. Other features include a Netafim mist system, Green Tek HAF fans and Hired Hand heaters, as well as 100 percent benched production space.