Blooming Nursery Is Saving With Solar

Dinsdale, whose Blooming Nursery just southwest of Portland is close to celebrating its 30th anniversary, chose solar energy to reduce the natural gas she was using to heat her greenhouse ranges that house a diverse portfolio of hardy perennials and other plants. One of the main reasons for the switch, she says, was to bring down energy costs.

“Our biggest input is labor,” she says. “Our second biggest input is energy.”

Why Solar?

A motivating factor that steered Dinsdale toward solar energy is an Oregon business energy tax credit equal to 50 percent of the total cost of the solar project. The credit can be amortized over a period of at least five years.

“It wouldn’t have made sense to do a project of this magnitude without the tax assistance,” she says.

While Dinsdale will have more of a tax credit than she can most likely use on her personal return, she will be able to sell the unused credits at a 30-percent discount to another entity, should she choose to do so.

Another reason for solar, Dinsdale says, is she wants to show that a solar project of this magnitude for a greenhouse operation is feasible. “It’s time for projects on a commercial rather than a token scale,” she says.

After researching solar contractors, Dinsdale chose Ra Energy of Portland to install her system. The system was installed to supply energy to a range of six greenhouses occupying 55,000 total square feet. Overall, Blooming Nursery uses about 140,000 square feet of heated greenhouse space.

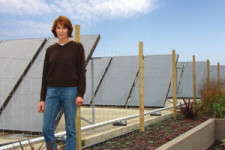

A total of 359 flat-plate, stationary solar thermal collectors, or panels, measuring four feet by eight feet, were installed on the project in two separate loops. All panels are oriented to face the average angle of the sun, toward the south. Solar energy collected by the panels heats up glycol running through copper tubing. The heat carried by the glycol transfers its energy to a closed-loop water system, which includes a 270,000-gallon, four-compartment underground, concrete holding tank about 100 feet away. The heated water is circulated through the greenhouse floor as needed through the fall, winter and spring seasons.

The majority of the panels were erected in a straight line above and adjacent to the greenhouse range. The remaining 55 sit atop the water holding tanks.

The system was installed so there are five ways to get the water to the appropriate temperature before it is delivered to the greenhouse floor. The solar panels installed at the nursery differ from electron-generating, photovoltaic panels in that instead of electrons transported by wires, heat energy is carried by glycol tubing inside the panels.

With photovoltaic panels, if any part of the panel is shaded, the circuit is broken, Dinsdale says. “With solar thermal, if any part is shaded they (absorb) a bit less (solar energy). The materials in the panels are designed to allow for maximum conductivity (of heat). The glycol heats up incredibly fast in the panels.”

In addition to the solar system, a series of underground, water-containing, in-ground loops are located around the storage tank at different levels.

“One application for these loops is to pick up heat that is lost through the walls of the tank,” Dinsdale says. This recaptured energy is then run through in-ground heat pumps, which multiply the heat energy present in the ground and send it to the greenhouse as supplemental heat during the colder winter months.

The Payback

Dinsdale says that by the time the solar system is running at top efficiency–by the end of this year–natural gas use for the range should drop to just 5 percent of what it was before the solar installation. That equates to about $50,000 in savings annually.

As for the payback period, when the net cost of the system is totally accounted for, including the tax incentives and the annual savings in energy generation, Dinsdale estimates it at slightly fewer than four years.

There are indirect benefits of using solar energy, as well. Dinsdale says plant quality is better, and the system gives Blooming Nursery a new marketing strategy to possibly implement.

“We are heating the roots now and not the air, and because we’re going to have control over the cost of our energy there’s no question in my mind that we’re going to be able to tailor the environment better to optimize growth,” Dinsdale says.

This will not only allow Blooming Nursery to offer plant material earlier than its competitors, but also broaden its product range because it is now possible to grow plants with higher heat requirements.

Another form of payback will be the excess heat energy collected by the system that can be used to heat the ground in cold frames or possibly even for drying crops, such as prunes and cherries.

Long-Lasting System

While the warranty on most of the equipment is for about two years, the expected life of the major components is between 30 and 50 years, Dinsdale says. “I’m counting on 50! It’s really going to make a difference for us going forward.”

Dinsdale adds that even though western Oregon has the image of a state in which the sun doesn’t show itself too often–especially from October through June–there still are enough heat units to fuel a collection and storage system. “We’re actually expecting to be able to collect a significant amount of radiation in the system all the way up to early December, and then starting again in mid-February.”

While there were some challenges during construction that usually occur the first time innovation ramps up, Dinsdale says she has no regrets about installing the solar system. That, in spite of the fact the cost was more than she expected and the project took longer to construct. “There’s never been a time I wished I hadn’t done this.”

Dinsdale does not want to disclose the cost of the project but did indicate it was a “significant investment.”

Ra Energy’s Bruce McLeod says Dinsdale’s solar system is the largest his company has ever installed, and that it’s probably the largest of its kind in the Northwest using solar-supported, in-ground heat pumps. Because of that, any challenges become magnified because of its size.

Even before the installation of the solar system, Dinsdale says her heating costs were lower than comparable operations due to the fact that she prefers to grow her plants on the cool side. “That’s because we want to produce a higher quality product as much as wanting to reduce the expense.”

Her solar-powered system will rest May through mid-September, when there’s enough ambient heat to do the job. “Then, all we’re doing is collecting,” Dinsdale says.