Costa High On New Hydration System

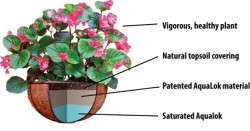

AquaLok, a sustainable hydration system from Freedom Garden Products that releases water and oxygen when plants need them, found a suitor in Costa Farms, which will develop new brands using AquaLok technology across garden centers in North and South America.

AquaLok technology allows consumers to expand the watering intervals for their plants, as it cuts the watering schedules in half. Some plant varieties can go a month between watering with the technology.

AquaLok, developed by Joe Byles, CEO and president of Freedom Garden Products, will also be available to other indoor and annual plant growers.

“Although I graduated with an aerospace engineering degree,” Byles says, “I was fortunate to combine my engineering background and work with top landscape and irrigation industries to develop new technologies that improve water conservation and save time and money for consumers.”

Costa Farms will make a presentation on Aqualok at Short Course in Columbus, Ohio, this Monday, July 13 from 7-8:30 p.m. Costa is hosting a cocktail reception at the Hyatt Regency Columbus in Franklin Room C and D. A special presentation will take place at 8.

“(Aqualok) is the biggest revolution to occur in ornamental horticulture in 25 years,” says Mike Rimland, research director at Costa Farms. ” This is really a big deal. It will change the ‘ease and succes factors for the consumer and also maintenance of our goods at retail.'”

The alliance between Costa and and Freedom Garden Products allows Freedom Garden Products to reach every market in the country.

“Aqualok will help consumers succeed at home with potted plants,” Byles says. “Costa’s sales, marketing and distribution expertise will put us on the map very quickly.”

The Aqualok technology also plays a key role in the latest Green Roof applications, as communities across the globe work to improve their eco-system. The Aqualok rooftop panels reduce storm water runoff, provide insulation/energy savings and reduce the carbon emissions in the environment.

“This new partnership with Freedom Garden Products opens new trails in patented technology products for home gardens and commercial applications,” says Jose Smith, CEO and president of Costa Farms.

Costa is test marketing the product this year in a limited rollout, with a full launch planned for Spring 2010.

For more information, visit www.costafarms.com.