Metrolina Greenhouses Has Improved Heating Efficiency With Green Solutions

Sustainability started to become a keyword in the horticulture industry in the late 2000s, when growers began converting their heating systems to greener options to save on energy costs and reduce their impact on the environment. However, there haven’t been many operations that have invested in sustainable solutions on as large of a scale as Metrolina Greenhouses at its Huntersville, NC, headquarters. Six years later, the operation is still fully committed to its biomass heating system and everything it entails.

[blackoutgallery id=”128529″]

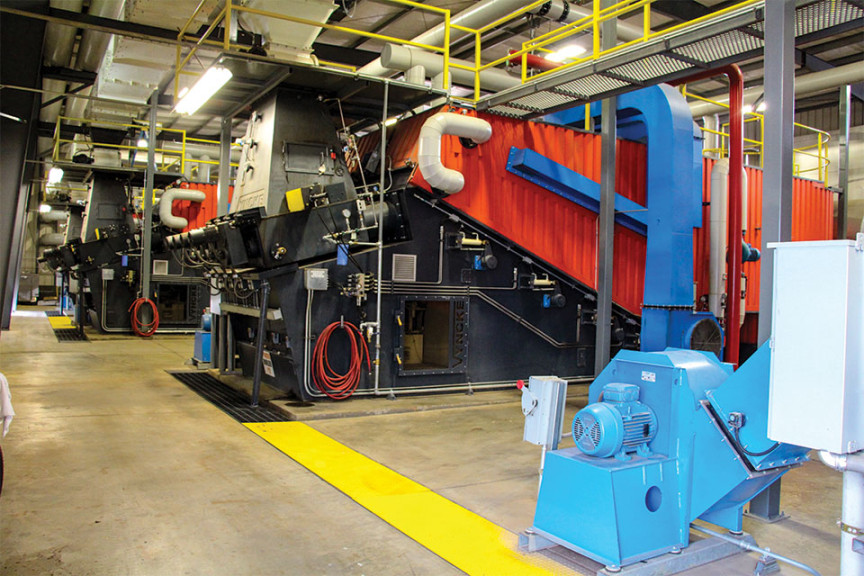

Metrolina first fired up its Vynke biomass system from Belgium in 2010. The four wood boilers cover 95% of the operation’s heating needs at its 201-acre main location in Huntersville, NC, and Metrolina still maintains its traditional heating systems for back up and to provide flexibility of resources.

Wood chips are sourced locally, with the majority from local forestry activities like wood harvesting companies and developers. The other portion, 30%, comes from old pallets. Using a resource like wood chips helps the environment, and boosts the local economy, says Director of Growing Ivan Tchakarov.

Metrolina dedicates a 4-acre barn to wood storage, and it can hold a supply of wood that lasts up to three to four weeks, depending on the outside temperatures and heating needs.

The wood chips are moved from the storage barn via a conveyor through a screening system to separate large pieces of wood and debris. Then the system’s conveyor belts move the wood chips at a steady rate to supply the Vyncke boilers. The conveyor belts are from FW Systems and Thermo Energy Systems (TES).

Sustainable Solutions Are Worth The Investment For Metrolina Greenhouses

At the beginning of the process to convert the operation to biomass boilers, Metrolina was able to secure a $390,000 grant working with Viability, which specializes in helping growers seek funding for alternative energy and energy conservation investments. The one-time credit allowed the operation to get started with the new system.

When it first started out, co-owner Art Van Wingerden estimated the return on investment would be 12 to 15 years. The thought then was if natural gas prices raised to $15 per therm, payback could be as fast as five years.

With gas prices currently at $5 per therm and wood costing Metrolina about $4 per therm, the return on investment still falls within the 12- to 15- year range, and Van Wingerden says that works for him. The benefits to the environment and the local economy make it worth the investment, he says.

“The payback is not as quick as we had hoped, but we are still glad we did it.”

Metrolina Greenhouses has looked into solar energy, but the investment doesn’t make financial sense currently, Van Wingerden says. The operation has not needed to install the Vyncke boilers at its York, SC, location, where it mostly grows perennials, and the minimal heat requirements are powered by natural gas.