Comparing LED Lighting To High-Pressure Sodium Lamps

Cuttings of vegetatively propagated bedding plants are frequently rooted in late winter and early spring to meet the spring and early summer market demand for flowering bedding plants. However, this is also the time when dirty and old glazing material, interior superstructures, and hanging baskets suspended above benches reduce already seasonally low ambient outdoor daily light integrals (DLIs) inside the greenhouse.

Increasing the DLI during propagation has been shown to improve growth and quality of rooted cuttings, as well as reduce time to flower after transplanting. While maintaining clean glazing material, minimizing superstructure and reducing the density of hanging baskets may increase greenhouse DLI, the only way to appreciably increase DLI is to provide supplemental or photosynthetic lighting.

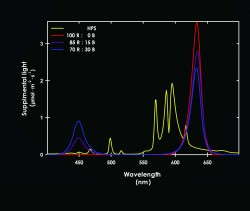

Light-emitting diodes (LEDs) are solid-state, semi-conducting diodes that can emit light from ~250 nm to ≥1000 nm. There are several features of LEDs that make them attractive alternatives to high-pressure sodium (HPS) lamps. First, LEDs can produce narrow-spectrum light at wavebands useful for plant growth and development, including blue (450 nm) and red (660 nm). Additionally, LEDs currently have a luminous efficiency of 38 percent (red) to 50 percent (blue) in converting energy to light and an estimated life of 50,000 luminous hours or more.

The interest in the use of LEDs is increasing in commercial plant production, and this is seen in the ever-increasing number of LED arrays seen in the marketplace. However, the impact and science underlying the use of LEDs as a supplemental light source in ornamental plant propagation of cuttings (liners) and seedlings (plugs) are not clear. Our goal in this study was to determine how LEDs providing light comprised of different wavelengths would stack up against HPS lamps when supplemental light was used

in propagation.

Preparing Cuttings For The Study

Unrooted cuttings of New Guinea impatiens, zonal geranium and petunia were received at Purdue University. They were subsequently stuck into 105-cell propagation trays filled with a substrate composed of (by volume) 1 part perlite and 2 parts soilless substrate (Fafard Mix 2). The trays of cuttings were then sprayed with a surfactant to minimize water collecting on the leaves and placed under mist in the greenhouse.

Immediately after being placed into propagation, cuttings were fertilized with 50 ppm N from a balanced fertilizer (Jack’s Professional 13-2-13 Plug Special LX). For the first seven days (the callusing period), the DLI was maintained at ~5 mol•m−2•d−1 and the air and substrate temperatures were maintained at 73°F.

After seven days, when roots started to appear at the base of the stem, cuttings were placed under one of four supplemental lighting treatments, each providing 70 µmol•m-2•s−1. One group of cuttings was propagated under HPS lamps, while the other cuttings were propagated under LED light comprised of different ratios of red:blue light, including 100:0, 85:15 and 70:30. The spectral distribution of the supplemental light from the HPS lamp and LED lights are shown in Figure 1.

Comparing Growth Of Cuttings Under Different Light Sources

Our first objective was to determine if light from LEDs varying in wavelength would affect cutting growth and morphology when compared to cuttings rooted under HPS lamps.

For New Guinea impatiens and geraniums, we saw virtually no statistical differences between cuttings rooted under HPS lamps or any of the LED light treatments. The root and shoot dry weight, stem length and stem caliper were all similar.

However, petunias exhibited a slightly different response. There was a slight increase in the root and shoot dry weight for petunia cuttings rooted under the LED lights, while stem length was also slightly shorter. However, while these differences were statistically significant, we didn’t find the results to have much commercial significance since the differences were so small. For example, the petunia cuttings rooted under LEDs were about one-fifth of an inch shorter than cuttings rooted under HPS lamps.

We also measured the photosynthetic rates of the cuttings under the different light treatments. Again, there were no differences in gas exchange for New Guinea impatiens, geranium and petunia across the different lighting treatments. While some LED manufacturers have claimed that light from LEDs will result in an increase in photosynthesis, our study found nothing that would support this claim.

In addition to the growth and photosynthesis of cuttings, we wanted to see if LEDs had any effect on the cuttings after transplanting. We observed little effect of supplemental light source during propagation on growth and morphology of finished plants. This included time to flower, stem length, node number below the first flower or inflorescence, flower bud number and the shoot dry weight.

The only significant effects observed were a slightly greater stem length and dry mass for petunias grown from cuttings propagated under 85:15 red:blue light when compared to plants finished from cuttings propagated under HPS lamps. Again, while statistically significant, they have little impact or commercial significance.

Finally, in addition to quantifying the effects of LEDs on the growth and flowering of cuttings, we wanted to assess the energy use of the different supplemental lights. The daily energy consumption of the HPS, and 100:0, 85:15, or 70:30 red:blue LEDs was 3.01, 3.29, 3.43, and 4.06 kWh•d-1, respectively. Blue light (450 nm) is a higher-energy light compared to red (635 nm), causing an increase in energy consumption with an increasing percentage of blue light.

Additionally, while LEDs do not produce radiant heat with the light that is emitted, there is heat generated by the diode itself. In order to maximize the long lifespan of LEDs, the heat must be removed from the diode and this can be achieved passively, with a material that would act as a heat sink, or actively with the use of air cooling.

Although the LEDs consumed more energy, the fans used to air-cool the arrays consumed 1.49 kWh per day and accounted for 37 to 45 percent of the total energy consumption for each LED array. Using a passive heat sink would reduce the energy use and, therefore, operating costs of the LED lights. However, a passive heat sink would also likely increase the size of the fixtures and initial investment cost.

When you are looking at LEDs for use as a supplemental light source, make sure to see how the LED lights are cooled and weigh the pros and cons of the energy consumption of actively cooled, minimal-shading lights versus passively cooled LEDs that could potentially increase shade in the greenhouse.

LED Lights Are Comparable With HPS Lamps

We found few differences among cuttings of New Guinea impatiens, geraniums or petunias propagated under HPS or LED lights. Furthermore, we observed no significant differences among cuttings grown under the different combinations of red and blue light from LEDs. As a result, we feel that LEDs are a suitable alternative supplemental light source for use during cutting propagation. However, our study highlighted the impact of LED design on the electrical efficiency of LED lights.

Next time you are considering using LED lights in your greenhouse, be sure to consider all the factors involved in LED design, including energy consumption and shading of LED arrays. For more information on LEDs, visit our team website at: http://leds.hrt.msu.edu.GG