Technology Provides Solutions For Growing In Drought

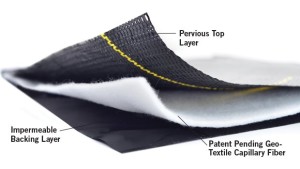

WaterPulse retail mats can help cut water use in retail settings.

In April, California Gov. Jerry Brown directed the State Water Resources Control Board to institute reductions in cities and towns across the state with the goal of reducing water usage by 25 percent. The announcement comes following the lowest snowpack ever recorded in the High Sierra. It was the first time in state history that action was taken to implement mandatory water restrictions.

In May, the farmers in California’s Sacramento-San Joaquin River Delta agreed to reduce their water use by 25 percent in exchange for assurance that they will not face further curtailment during the June to September growing season. Their proposal was approved by the State Water Resources Control Board.

Growers who participate in the program could opt to either reduce water diversions under their riparian rights by 25 percent, or fallow 25 percent of their land.

Given these conditions, growers and retailers are in need of methods and technology that can best minimize the use of water to lower costs, reduce water use, or simply show solidarity with residents and municipalities who are facing cuts.

Suppliers are responding to the need with products that help use water more efficiently, save money, reduce water use and keep plants healthy.

WaterPulse, Inc. Allows Growers To Save Water Without Reducing Plantings

WaterPulse, Inc., founded in 2012, has developed a capillary action mat system to help growers cut water use in greenhouses and nurseries.

WaterPulse has spent the past three years working with retailers and growers to perfect its new watering system, an irrigation system that dramatically cuts water consumption while reducing expenses. WaterPulse has been tested in production environments over the last few years, and after showing consistent positive results, the company moved into full production.

WaterPulse Retail Mat

The new product is a commercial-grade, capillary-action mat system that, according to information provided by WaterPulse, cuts the water use in retail outlets, greenhouses and nurseries by up to 70 percent. The capillary-action mats deliver water and nutrients uniformly to the roots of the plant, for more consistent plants. In addition, the soil will only draw up as much water as it can use, reducing the spread of water-borne disease and protecting plants from root rot.

The mats are designed using a patent-pending geotextile that works differently than what has been commercially available in the past. They are filled with a proprietary combination of blended fibers designed to move water at a specified rate and reduce the amount of water required. Because WaterPulse mats actually move the water through the fibers, water can flow at various rates at various locations on the same mat. This means less water is required to be applied to the mat, and allows the mat to pulse from a wet state to a dry state at a quick rate, keeping the root systems of the plants from being drowned in the mat.

The water-saving effects of WaterPulse could mean that certain growers, such as those in California who have committed to reducing their consumption, could save water without reducing plantings.

“Installing WaterPulse mats in greenhouses, nurseries and garden centers has been shown to save around 70 percent of the water it would take to do the same job by hand or with overhead sprinklers, and the plants are healthier,” says Jim Heffernan, CEO and executive chairman of WaterPulse. “That means no reduction in planting — and savings well in excess of the target.”

According to Heffernan, the average greenhouse uses 11,000 to 22,000 gallons of water per acre per irrigation day, while nurseries typically use 27,000. Using WaterPulse mats can save between 7,700 and 18,900 gallons of water per acre per irrigation day.

To read more about WaterPulse, visit waterpulse.com.

Stockosorb Can Help Reduce Loss At Retail

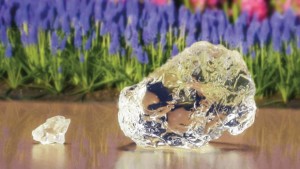

Stockosorb from Evonik is an advanced hydrogel blended into planting media to increase the water-holding capacity, while also decreasing water and nutrient losses due to seepage, evaporation and runoff. The product is a potassium, cross-linked polyacrylate, water-absorbing polymer, also referred to as Superabsorbent Polymers (SAPs). As plants are watered, the polymers absorb and store many times their weight in water.

Evonik Stockosorb 660 is an advanced hydrogel technology that allows soil to increase its capacity to retain water. The product has to be blended at the time of potting, and the gel activates once watering starts. As the soil dries out, the nutrient-rich water is slowly released into the plant’s root zone.

Stockosorb uses advanced hydrogel technology. Hydrogel, a Superabsorbent Polymer (SAP), can store many times its weight in water.

By adding Stockosorb to growing media, plants ultimately require less watering, and have a more stable and consistent moisture level with improved plant growth. With the rising cost of water, the Stockosorb advanced hydrogel technology allows growers to better manage their water use in a more responsible manner.

In ideal conditions, the gel can be left in the soil for three years, says John Wynne, business development manager for Evonik. The hydrogel continues the cycles of absorption and release and will typically last 18 months to three years.

When Wynne started with the company four years ago, he says he noticed that growers were struggling with ensuring that their plants have adequate water at the retail level.

“With the drought out West, the losses on the retail side are skyrocketing,” Wynne says. “Even if a store has merchandisers, if there are water cuts, they can only water so much. Growers can’t control that.”

Incorporating Stockosorb can delay wilt, and allow plants to survive without water an extra day or two, Wynne says.

Next, Evonik will focus on how it can help growers before their plants go to retail. For example, on the production side, there may be 10 irrigation techs making sure plants are being watered properly.

“If you have an insurance policy in the soil like Stockosorb, that’s going to help. Maybe instead of 10 irrigation techs, you could use eight,” Wynne says. “It buys you another 10 to 12 hours. That’s a tool in the soil that can help you do that.”

The company has been doing trials with growers in an effort to examine all of the factors that could impact the effectiveness of Stockosorb on the production side.

See “Talking Shop” on page 82 to learn how Bob’s Market and Greenhouse is using the product. For more information, visit stockosorb.com

Sensor Technology Helps Prevent Over- or Under-Watering

Decagon Devices and Damatex have developed sensor technology that allows growers to set the parameters for automated watering, saving time and water and reducing the risk of disease, because plants are getting the water they need, when they need it.

The technology includes electronic, sensor-driven water pulsing irrigation that can water crops more precisely than grower-controlled methods. The sensors are inserted into the soil and can be programmed so growers can trigger the sensors after a certain amount of time, or when plants hit a moisture low. The system maintains a set point of optimum moisture, eliminating stress and helping plants to thrive.

Visit bit.ly/precisionhort to read more about the system.

Another product worth considering is Rapid Automated’s Water Logic System, an easy add-on to your hanging basket system that measures mass and waters based on need.

Some growers experience inconsistencies with their watering systems, with some varieties drying out too quickly, while others get overwatered. The Water Logic System handles those variations by weighing the baskets, and determining whether each basket needs to be watered or not, based on weight.

It is a simple rod and weight system that is easily adjustable, with no programming required. The grower just has to adjust the weight on the rod. As a basket goes by, it pushes on a balance. If the basket is too heavy, it simply passes by un-watered.

See how it works at bit.ly/waterlogicsystem.