The Energy Efficient Greenhouse

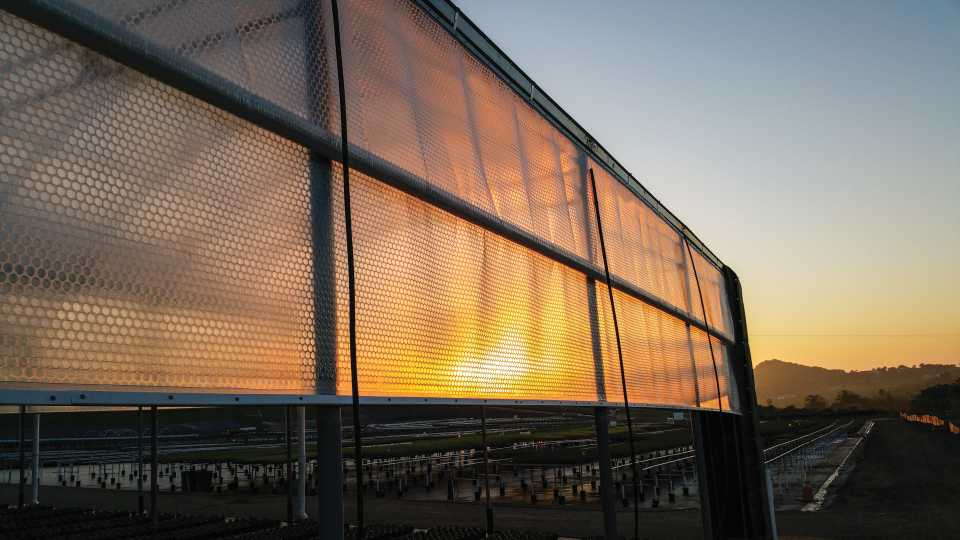

SolaWrap 12-Foot Roll Up Curtain

When it comes to covering a greenhouse, all growers want similar things: strength, durability, protection from the elements, energy efficiency and cost savings. Today’s technology rises to the challenge by offering a variety of products that improve growing conditions inside, no matter what the weather’s doing outside. We checked with manufacturers to see what’s new and uncovered some best practices for buttoning up your greenhouse. Here’s what you need to know about the latest trends.

Trend 1: Diffused Light

As any grower knows, light and temperature are two keys to cultivating a successful crop. In the past, coverings didn’t account for light variations within the structure. To avoid uneven crop production, someone would have to rotate the plants inside the greenhouse. Diffuse films, such as AT Films’ Luminance, solve this problem.

“Diffusing the light as it enters the greenhouse helps evenly disperse it throughout the greenhouse, creating a much more even light canopy,” says AT Film’s Account Manager Amy Lynch.

“This means the plants are getting light all around them and not just in the direct light path of the sun, therefore reducing stretching. The dispersion of light will eliminate shadows within the greenhouse, which is especially beneficial to the grower who has hanging baskets and bedding plants. Luminance will also help reduce the heat load in the greenhouse in the warmer months and reduce the amount of temperature spikes throughout the day. And it’s a thermal film, so it will help to retain more heat in the cooler months.”

Trend 2: Durability

Many of today’s films have an unmatched durability that becomes apparent when growers look to the warranty. Some companies tout a 10-year guarantee with a life expectancy of up to 30 years.

“One trend in coverings are better films that last for a long, long time,” says SolaWrap’s Agricultural Sales Manager Kenneth Aguilar. “When choosing a covering, a grower should consider light, strength for snow and wind, life expectancy and the warranty of the manufacturer.”

In the durability category, Aguilar says SolaWrap can take quite a beating. The product’s snow load is 120 pounds per square foot, and it has a wind load of 122-plus miles per hour.

Trend 3: Flexibility

Growers often have a number of different structures to accommodate their production needs. Thankfully, this doesn’t necessarily require different coverings for each one. Part of Solexx’s charm, for example, is versatility.

“Many coverings are made of polycarbonate, but Solexx is made with high-density polyethylene. The difference is that it’s flexible,” says Blair Busenbark, chief operating officer at Adaptive Plastics, the company that makes Solexx. “It can go over hoop houses or arched structures. Solexx can be used on sidewalls, doors — anywhere you can think to put it. If you crease it, you can bend it back or run it around the corner. This results in a very tight greenhouse.”

Horizontal and vertical installation with pre-cut or custom length rolls also means less waste and fewer seams for optimally insulated structures.

Trend 4: Layers

The saying is “less is more,” but some coverings manufacturers have found that more film is actually more efficient. Lumite, the company behind Sun Master greenhouse films, is coming out with the EVO line in the second quarter of 2015. These films are essentially two products in one — a clear thermal film on top with an anti-condensate on the bottom.

“It looks like a single piece but has seven separate layers,” says Lumite consultant Tom Gipson. “To combine the thermal film and the anti-condensate, the film needed a middle layer that would separate the two products. We found a resin to put in the middle layer that doesn’t adhere to the thermal part. Half of the company believes the two-in-one part will be the most sought after benefit of the EVO line. Others believe it will be the lifetime condensation control guarantee. The last technology to be of any consequence to the market was when manufacturers switched from green to clear films.”

Another company that has bought into the layering concept is AT Films.

“With the upgrade to our new seven-layer extrusion line, we’ve developed the new SmartStructure technology that will enhance the performance of our current films in the Dura-Film family of products, as well as open doors for the development of new products,” Lynch says. “Just by using this new technology, we have already seen a 30 percent improvement in dart impact for our widely popular Super 4 film. This improvement was seen without making any formulation changes. By simply structuring the film differently, we made it stronger.”

Climate screens help reduce energy costs.

Trend 5: Reduced Energy Costs

The new covering technology may involve more durable materials or better light distribution, but all the trends focus on manufacturers’ biggest priority: increasing energy efficiency so growers save money.

Since production and energy costs regularly top the list of growing expenses, it’s easy to see why companies highlight this benefit and want to work with growers on selecting the right product for their needs.

Ludvig Svensson, manufacturer of smart textiles for the greenhouse, went through a major change last summer in order to become a climate partner for growers.

This meant overhauling its method for classifying climate screens in order to help growers identify their ideal product. While there are hundreds of combinations and variants, the screens are divided into five families based on use.

The Solaro family, for example, offers sun protection, and Obscura offers a range of light restriction options, including total blackout.

“It’s now easier for a grower or greenhouse builder to say, ‘Okay, I need something for shade.’ Then they go deeper, ‘Okay, I want 50 percent shade,’ and then they narrow down the process,” explains president of Svensson’s American operation Mauricio Manotas. “The new website and ordering system has been well-received with new users.”

For those who aren’t exactly sure what they want, Svensson continues to put together customized plans for growers.

“The screens work in any situation. Some work outside, some inside,” Manotas says. “We have options for any market, and we encourage customers to ask a lot of questions before deciding on a screen. I’ve seen people pick the wrong one, and they don’t get the results they expect. The problem is with choice, not with the screen.”

If purchasing a new covering isn’t an option, one way to reduce energy-related costs is to conduct self-audits on a regular basis. To ensure your operation is running efficiently, check out these resources.