Drones and Scouting Tools Bring New Automation Options Into the Greenhouse

Using Corvus’ drones, growers define the greenhouse flight route in a flight control web app, link a task to the drone, put the drone on the main aisle, and push the start button. Photo: Corvus Drones

Protecting and maintaining the health of your plants is becoming more high-tech than ever, and the timing is perfect. After all, scouting is critical, but it is also very labor-intensive. From drones to cameras to artificial intelligence, here’s a closer look at the latest innovations from a range of technology solution providers.

Drones for Data Collection

Frans-Peter Dechering, who co-founded Corvus Drones with Gerhold ten Voorde about three years ago, says the company’s main focus is indoor navigation.

“We partner with computer vision companies because there are so many domains that require knowledge,” Dechering says. “By partnering, we are able to grow faster and help more growers.”

Using Corvus’ drones, growers define the greenhouse flight route in a flight control web app, link a task to the drone, put the drone on the main aisle, and push the start button. The drone then executes the task automatically, leading to a number of benefits, including:

- Seed germination: improves square meter efficiency and saves time.

- Leaf area index measurement and growth monitoring minimizes crop risks.

- Flower detection improves the readiness stage to optimize customer delivery.

The long-term goal for Corvus is to digitize every plant in every greenhouse all over the world. In March 2022, the award-winning company introduced its first application for seed germination, adding to its current offerings for leaf area index measurement, growth monitoring, and flower detection.

“We work with breeding companies, young plant producers, and pot plant producers,” Dechering says. “High-wire crops like tomato are part of the development road map (Corvus expects to have autonomous navigation by the end of 2023), as is inventory management, a specific demand from North American producers.” Goals further down the line include pest and disease scouting.

Of course, when it comes to making the transition to this type of technology, there can be grower apprehension and concerns about return on investment (ROI).

“We have to realize that we are in the midst of a big digital transformation in horticulture, and not every grower is ready for that,” Dechering says. “As a technology provider, we should be focused on solutions. We have a subscription business model, and we take care of all the maintenance, software updates etc., so the grower can focus on the information.”

Scouting Pests with Cameras

Plantfellow, a Netherlands-based software and data company, has spent the past few years developing and testing two greenhouse innovations that it hopes will be ready for a large-scale market launch in 2023: the digital scouting solution ScoutCam and the phenotyping solution AutoPheno.

The ScoutCam has been tested in cucumber, bell pepper, tomato, chrysanthemum, and gerbera, with a primary focus on monitoring for thrips.

“We are now seeing the first positive results in greenhouses, which is unique with this kind of system for thrips,” says Jasper van der Auweraert, Innovation Developer at Plantfellow. “Insects fly everywhere, and the next step will be the monitoring of biological control agents.”

What sets the ScoutCam apart, according to van der Auweraert, is its stable digital count.

“There are systems for counting whiteflies using a mobile phone, but such systems are more sensitive to light and to the person taking the photos than our system is,” he says. “This is because we attach the system to a greenhouse column, which gives it stability. We also have control over the lighting and the sharpness of the photos.”

Now that the technology works, Plantfellow is looking to translate the data for the ScoutCam into information that the grower can use immediately.

“The information must be of immediate practical use. Think, for example, of the translation of a figure about the number of pest insects caught on a sticky trap into when the grower needs to apply his biologicals,” van der Auweraert says of the data. “It’s about converting camera information into information for the grower.”

While the company’s current focus is on the Netherlands, it is also exploring other markets, including the U.S.

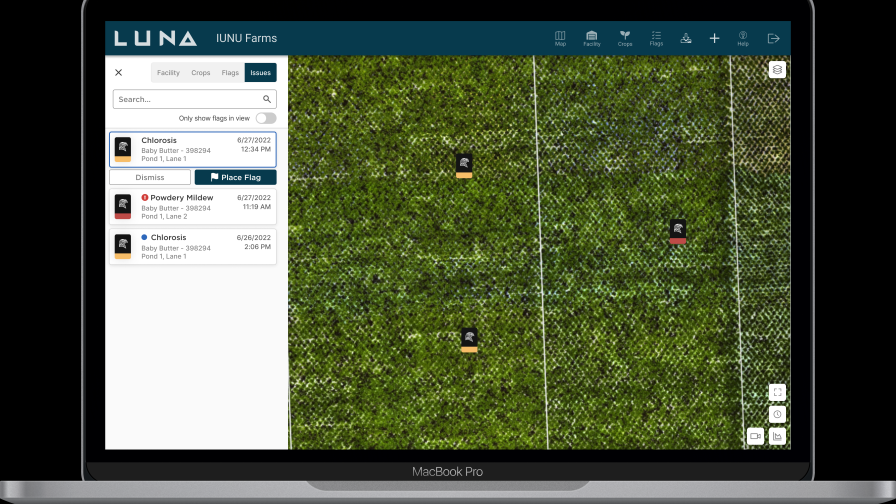

IUNU recently released its Intelligent Issue Detection out of the beta stage. Along with IUNU’s LUNA AI, growers can eliminate the process of manual scouting. Photo: IUNU

Reducing Labor Dependency

Labor is the no. 1 concern for most growers right now, and as a result, they’re finding new ways to reduce labor dependency through automation. One of the things IUNU does to help growers understand return on investment (ROI) for new scouting technology is present them with the expected ROI right from the beginning.

“We can analyze their current processes and use the known ROI and case studies to create a plan with exactly where the grower will see value,” says Allison Kopf, Chief Growth Officer at IUNU.

IUNU recently released its Intelligent Issue Detection out of the beta stage. Along with IUNU’s LUNA AI, growers can eliminate the process of manual scouting. Using a combination of artificial intelligence and machine vision, LUNA AI autonomously scouts the entire facility and alerts growers when there are issues. This eliminates scouting labor and delivers insights faster and more accurately for the entire facility, rather than just samples or wherever sticky cards are.

“Ultimately, this helps cut down on both labor and spend on chemicals/beneficials as growers can pinpoint exact issues and locations,” Kopf says.

IUNU works with greenhouses and vertical farms, with growers of ornamentals, lettuce and leafy greens, cannabis, and just recently, vine crops.

“We’ve worked with growers to reduce and often eliminate their loss due to chlorosis, necrosis, mildew, tip burn, thrips, spider mites, aphids, and many more diseases and pests,” Kopf says.

Scouting that Benefits Biologicals

Thanks to an alliance with technology company PATS, growers who use Biobest’s extensive portfolio of integrated pest management (IPM) solutions can now take advantage of PATS-C, a system that detects real-time flying pests, such as moths, in the greenhouse. This data allows for an earlier and more accurate introduction of biological agents. Learn more here.