The Top 100 Growers Tackle Crop Protection Challenges

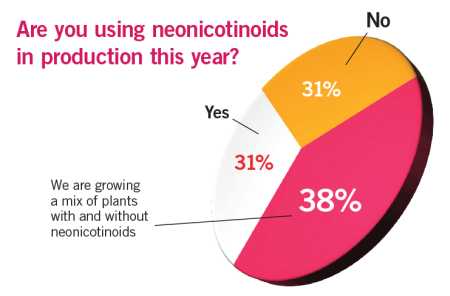

The Top 100 Growers were fairly divided in the way they approached pest control this year. In response to a mix of pressures, from consumer concerns over the use of neonicotinoids to retailer mandates, as well as growers increasing their use of biocontrols and increased focus on integrated pest management (IPM), 31 percent opted not to use neonics this year, while another 31 percent have kept neonics in rotation. Another 38 percent are growing a mix of plants with and without neonicotinoids.

The Top 100 Growers were fairly divided in the way they approached pest control this year. In response to a mix of pressures, from consumer concerns over the use of neonicotinoids to retailer mandates, as well as growers increasing their use of biocontrols and increased focus on integrated pest management (IPM), 31 percent opted not to use neonics this year, while another 31 percent have kept neonics in rotation. Another 38 percent are growing a mix of plants with and without neonicotinoids.

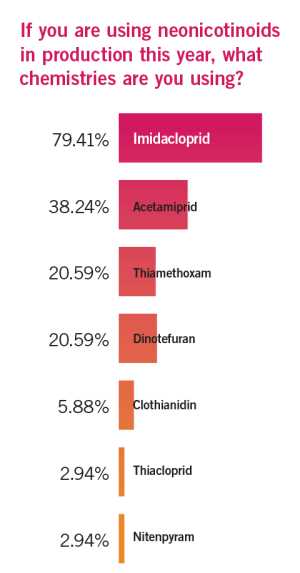

Of those using neonics, the most predominantly used chemistries are imidacloprid (79 percent), acetamiprid (38 percent) dinotefuran (21 percent) and thiamethoxam (21 percent).

“We are looking at other products, but we also are using the products properly and responsibly,” said Brad Bloes of Panzer Nursery.

Chad Corso of Corso’s Perennials said, “We are using very little neonics for 2015. We do have it on the shelf if we have a situation that we cannot get under control. The only items treated this year were hanging baskets.”

Growers who are keeping neonics in their toolbox have a range of opinions and theories about how they will go forward using the class of chemicals.

“Neonics have been reduced to about 3 percent of our chemical use on outdoor flowering plants,” said Jose Smith of Costa Farms. “That said, we are actively working to further reduce use of neonics.”

Tom Fessler of Woodburn Nursery & Azaleas said he is not convinced neonics are the problem, and does not plan on making changes.

“Science tells us these products are safer to use than the alternatives,” Fessler said.

Those who opted not to use neonics this year said they instead used alternative chemistries like Mainspring, XXspire AzaGuard, Rycar and Kontos, as well as traditional (older) chemicals, more biopesticides, beneficial insects and predacious insects.

They’re also closely monitoring a number of factors to compare the changes in their production practices to when they were using neonics, including the number of applications of other chemistries (70 percent), cost of other chemistries (65 percent), restricted entry interval (REI) times of other chemistries (52 percent), employee health (35 percent), shrink (35 percent) and sales (26 percent).

The Top 100 Growers plan to consider the following factors to determine what production practices they’ll use during the 2016 growing season, based on this season: financial costs related to production (60 percent), sell-through of plants (55 percent), profits (53 percent), retail consumer reaction to neonicotinoids (52 percent), management costs related to production (employee health, REI, etc.; 48 percent) and continued labeling of plants applied with neonicotinoids (23 percent).

“We have had some discussion about balancing the wishes of the consumer with production,” said Lisa Ambrosio of Wenke/Sunbelt Greenhouses. “We have had to spray more frequently, which makes for some unhappy growers.”

Changes In Crop Protection

Changes In Crop Protection

Overall, growers have changed their production practices in many ways since so much attention has been placed on the use of neonicotinoids.

Among the Top 100 Growers, 84 percent have increased use of IPM and 60 percent have increased their use of biocontrols to reduce the use of pest control products. Other ways they’ve scaled back include using insect exclusion from greenhouses using thrips screening (16 percent) and double-door entries (5 percent), and switching to organic controls (9 percent).

Over the past five years, biological control use among 68 percent of the Top 100 Growers has increased. Growers are primarily using biopesticides (69 percent), predatory insects 65 percent), beneficial insects (64 percent), insect growth regulators (56 percent) and biostimulants (24 percent).

Generally, growers using biocontrols say they have observed that they perform as expected (75 percent), while 19 percent say they’re better than expected and 5 percent say they don’t perform as well.

Effectiveness is the number one factor that would motivate growers to use or increase use of biocontrols (44 percent), followed by cost efficiency (22 percent), buyer requirement (12 percent) and resistance management (10 percent).

Eduard Van Wingerden of Ever-Bloom said, “I don’t think I would be able to grow gerberas as effectively without biocontrols. Once you get over the learning curve, it’s a very powerful tool.”

Half of the growers who don’t use biocontrols say they don’t because they feel traditional crop protection products work better than biocontrols. Other reasons growers gave were that biocontrols aren’t as effective, they’re too expensive and they don’t know enough about biocontrols to use them effectively (each with 17 percent).

“Biocontrols do not work in a ‘zero tolerance’ environment,” said Anthony Vollering of Grolink Plant Co.

Now that major crop protection companies are adding biocontrols to their portfolios, however, 60 percent of the growers said they’d be more likely to use them, but 40 percent said that doesn’t influence them.

Promoting Responsible Practices

Despite the change in their production practices to include more IPM, 73 percent of growers said they have not changed the pricing of their crops, but 28 percent said they have increased prices to reflect these efforts. Growers said they’d like to see their retailer buyers respond to changes in production practices.

“Support price increases due to the added burden to growers,” said Nirmal Shah of Plants Unlimited. “Organic foods support prices; ornamentals should, too.”

Marco Verdel of Battlefield Farms said, “At least recognize what we are doing and that our industry is not bad for the environment. We always like to get an increase in prices.”

The Top 100 Growers are working toward improving awareness about protecting pollinators, and they’re making efforts to educate retailers and consumers about their own production practices.

“We have prepared a packet of articles and have given several talks sharing how growers produce the plants,” said James Russell of Armstrong Growers.

Jonathan Cude of Sedan Floral is using industry resources to speak for him, to help educate customers.

“We hosted an open house in March, and had Dr. Raymond Cloyd from Kansas State give a talk on the issue,” he said.

Many growers said they discuss their practices with buyers, and promote their efforts on their care tags, websites, in eMails, on social media and during tours.

“We have a prepared statement, which indicates, in general terms, our commitment to only use pesticides when absolutely necessary,” said Chris McCorkle of McCorkle Nurseries. “Additionally, we state our use of IPM and strict adherence to the safe use of all labeled plant protection products.”