Getting The Most Out Of Light Measurements

Does the quality of your greenhouse-grown plants or number of cut flowers harvested decrease in the winter? Do your cuttings take longer to fully root during certain times of the year? Do you own HID lamps but don’t know when you should use them? If your answer is yes to any of these questions, this article will shine some light on how to solve some of these production problems.

In commercial greenhouses, growers can implement several strategies to increase quality and yield, decrease propagation or production time, and enhance root and shoot development of seedlings and cuttings. One fundamental way this can be achieved is by successfully managing and manipulating greenhouse light levels. However, before managing the light in your greenhouse, it is important to know what type of light you are measuring, how to measure it and how manipulating it will affect your crops.

Measuring Light 101

The footcandle and lux are the most common units used to measure instantaneous light in the United States and other parts of the world, respectively. However, growers should understand the limitations of using these photometric units.

First, photometric units are instantaneous readings that do not accurately represent the amount of light a plant has received during a 24-hour period. Second, photometric units represent the amount of light perceived by the human eye (primarily green light, which is the type of light plants do not absorb and only reflect) and are not correlated to plant photosynthesis.

Another measure of light that is directly correlated to photosynthesis is quantum light. Quantum light, which is also an instantaneous measurement, is widely used by horticultural researchers and is expressed in µmol.m-2.s-1. This type of light quantifies the number of photons that are used for photosynthesis falling in a square meter per second.

Daily Light Integral

Are you familiar with the term daily light integral or DLI? DLI is the amount of photosynthetically active radiation (PAR) between 400 and 700 nm (the wavelength of light that plants perceive for photosynthesis) received each day as a function of light intensity (instantaneous light) and duration (daylength or photoperiod). In other words, DLI is the cumulative amount of light received by your plants during a 24-hour period.

Conceptually, it is similar to how we measure rainfall. Light is “collected” cumulatively throughout the day, similar to how rain is collected in a rain gauge during a storm. Because DLI is measured over the course of the day it is expressed as moles per square meter per day, or mol.m-2.d-1.

DLI’s Importance

DLI is a very important measurement for greenhouse growers because it influences plant growth, development, yield and quality. For example, DLI affects rooting and aboveground growth of seedlings and cuttings, time to flower, and finish plant quality, including branching, compactness, stem caliper, flower number and size.

So how can you use DLI in your greenhouse? First, familiarize yourself with crop-specific DLI recommendations, which are available in English and Spanish. Or, download a pamphlet for greenhouse use at the same website. Next, begin monitoring and recording the DLI inside your greenhouse. Knowing the DLI inside your greenhouse and crop DLI requirements will allow you to determine when supplemental lighting, white wash or retractable shade curtains are needed to produce a premium product.

DLI During Propagation

The vast majority of cutting and seed propagation takes place from December to March when outdoor DLI levels are between 5 and 30 mol.m-2.d-1 across the U.S. However, when we take into account the shading from greenhouse structures, glazing materials, thermal curtains and hanging baskets, DLI values are often reduced by 40 to 70 percent.

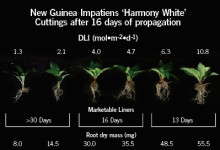

Consequently, if you are propagating greenhouse crops under light-limiting conditions (low DLI), you can expect delayed rooting, growth and development. How do you know your crops are growing under limited DLI values? During propagation of most herbaceous crops, researchers at Michigan State and Purdue Universities have found that providing between 4 and 5 mol.m-2.d-1 from sowing/sticking until rooting initiation/callusing–then increasing DLI between 6 to 8 mol.m -2.d-1– will promote rooting and enhance shoot and root biomass accumulation (Figure 1). Providing an optimum DLI during propagation can decrease propagation time, enhance rooting and compactness to facilitate shipping and transplant, and reduce subsequent time to flower.

DLI During Finishing

The DLI during finishing is very important for producing high-quality crops. Generally, increasing the DLI during finishing can produce more compact plants, while increasing the number of branches, flowers and overall plant mass. Additionally, increasing the DLI can also reduce the time to flower by reducing the number of leaves unfolded before the first flower or inflorescence (facultative irradiance response) or by increasing the rate of plant development through the radiant heat generated from increased irradiance.

However, all crops do not have the same DLI requirements. Jim Faust from Clemson University categorized crops based on DLI requirements of 5 to 10, 10 to 20, 20 to 30 and greater than 30 mol.m-2.d-1 as low, medium, high and very high-light crops, respectively. Identifying the optimal DLI for the crops you are producing is a great step to take toward producing a high-quality finished plant.

How Do We Measure DLI?

There are several ways to quantify the DLI in your greenhouse, including estimating, calculating and measuring. These options range in accuracy and cost from low to high and as cost or accuracy increases, generally the other will as well–and vice versa.

Greenhouse growers can estimate outdoor DLI levels by locating their facilities on DLI maps developed by Jim Faust and colleagues. These maps illustrate monthly outdoor DLI throughout the U.S. But again, these values should be reduced by 40 to 70 percent to give you very rough estimates of the DLI values your greenhouse-grown crops are receiving each month.

Another method to calculate DLI is placing a quantum sensor near your crop (Figure 2). The sensor can be connected to a data logger, or environmental computer that records instantaneous light intensity (commonly footcandles, or µmol.m-2.s-1) over defined intervals (once every 10 to 60 seconds). Using the calculations in Table 1 in a spreadsheet, the 24-hour DLI can be calculated based on average hourly readings in either footcandles or µmol.m-2.s-1.

Finally, as greenhouse growers, you can now purchase devices that automatically measure the DLI your crops are receiving. This can be done with either mobile or self-contained units. The LightScout DLI 100 meter (Figure 3) and the WatchDog Weather Station (Figure 4) are two mobile, self-contained devices manufactured by Spectrum Technologies that are portable tools for measuring DLI.

While DLIs are not logged and stored in the LightScout, the WatchDog has a built-in data logger that records daily values and can be connected to a computer to export data. It is important to remember that all light sensors should be placed next to your crop and be kept at canopy height to accurately measure DLI.

What’s Next?

Once you know the DLI requirement for your crops and you have estimated the monthly DLI levels in your greenhouse, it is time to make light management decisions. You can decide if supplemental lighting or shade curtains are profitable investments for your facility. Under cloudy days and extended overcast periods (winter and early spring), the use of HID lamps to supplement sunlight allows growers to increase plant quality and productivity. HID lamps, such as high-pressure sodium lamps, are a good way to maximize effectiveness of supplemental light because these types of lamps are efficient in converting energy into photosynthetic light. Most greenhouse crops benefit from supplemental lighting, but this technology is only worthwhile when increased crop quality or reduced production time leads to increased revenue and, ultimately, profitability.