Revol Greens Leads the Way in Lettuce Innovation

Revol Greens may be a relatively new player in the indoor leafy greens market, but since commencing operations in 2017, the Owatonna, MN-based company has quickly made a name for itself. Revol’s first 2.5-acre greenhouse began shipping in 2018, and less than three years later, the company expanded to 10 acres of year-round growing capacity. Soon after came expansion plans into Texas and California, giving the company access to several metropolitan areas where product could be shipped within a day.

Today, Revol Greens grows both baby leaf (green and red leaf, arugula, baby romaine, kale, butter) and head lettuces (butterhead and Romaine). While its current Minnesota greenhouses are an even mix of organic and conventional products, future sites will be 100% organic.

Despite this rapid growth, the company is grounded in its commitment to producing a high-quality crop, backed by an experienced leadership team whose goal is to ensure consistency from the Heartland to the West Coast.

Experience at the Top

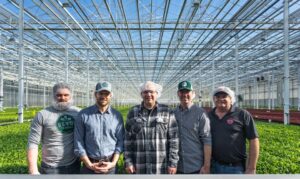

The ownership structure at Revol Greens is made up of several seasoned veterans of the vegetable industry, some of whom include:

- Marco de Bruin: Founder and Technology Advisor. De Bruin leads the greenhouse design and overall growing strategy.

- Marc Vergeldt: Director of R&D. Based in the Netherlands, Vergeldt leads research into new varieties and technologies, using his connections in the world of Dutch horticulture and his previous work as an industry consultant.

- Steve Amundson: Head Grower and leader of the growing team.

- Brendon Krieg: Vice President of Sales and Marketing; Krieg previously worked for Target, where he honed his knowledge in produce retail.

Much of this group had been partners together at Bushel Boy Farms, an Owatonna-based greenhouse tomato producer that decided to start its own company with a focus on the emerging leafy greens category.

A Scaled Growth Plan

Expansion is taking place quickly at Revol Greens. Only a year after expanding to 10 acres in Minnesota, the company is nearing completion of a 16-acre facility in Tehachapi, CA, and recently announced it will be adding a site in Temple, TX.

“Our plan is to approach production and sales from these facilities from a local and regional level, with a national reach,” Krieg says. “We want to be able to deliver within a 500-mile radius from each facility within a day.”

The national scale comes in the connections with larger retail and foodservice buyers.

That may seem like a lofty goal, but when you’re competing with experienced field growers, it’s necessary, Krieg says.

“What we’re hoping to do is to bring a solution that can compete with organic field-grown product, while gaining a little bit more shelf space than you might see from a greenhouse,” Krieg says. “You’ve got conventional, and you’ve got organic; we think greenhouse lettuce complements this as a premium sustainable solution.”

To attain this scaled level of expansion, consistency across each region is important. This is why Krieg and another partner, Tom Thompson, Revol’s Chief Revenue Officer, emphasize that each facility is designed to be similar, so that even with the differences in regional climates, the growing, harvesting, and packing systems are the same.

From Growing to Harvesting

Deciding on the ideal production systems and technological innovation requires trial and error, especially when the leafy greens category is so diverse.

“Many of our systems are Dutch-based, and as we bring them over, we test them in each crop to decide the most appropriate fit,” Krieg says. “Our end goal is to develop a customized solution for each one of those items.”

This is where scaling matters; as Revol Greens adds larger facilities, Krieg says it will be easier to segment crops into 3- or 4-acre blocks versus trying to grow them side by side in small areas of the greenhouse.

As these decisions are being made, Vergeldt points out they’ve helped Revol Greens fortify its competitive advantage as an indoor producer.

“Because the crop is protected, we don’t have the weather or heavy pest pressure that field growers face, and we can also better manage the photosynthetic process through light manipulation,” Vergeldt says. “All of this leads to a better-quality crop.”

There are still challenges, to be sure, including water supply and quality.

“Water is becoming a critical resource in all areas, especially in California,” Vergeldt says. “Even though we’re using less than 10% of the water that is used outdoors, we still need to become more aware of how we’re using it.”

This includes treating flume boards as the crop moves through the greenhouse.

“It doesn’t make sense if we reduce water waste when growing the crop, and then turn around and waste it by using excessive water to clean the boards,” he says.

When it comes to technology adoption, Krieg says there’s a three-part decision-making process.

“We start by looking at what can make us better from a quality standpoint,” Krieg says. “Then we look at the return on investment, followed by how we can create more tech-based jobs for our production team.”

A Roadmap for Success

The lessons learned today are helping Revol Greens continue to plan for the future.

“Because we’re taking a crop from seed to harvest within three weeks, the amount of data we’re collecting is too much for a human to process,” Vergeldt says. “We need artificial intelligence to analyze it, and that’s something we’ll be looking at in the near future.”

Above all else, the team at Revol Greens recognizes that even when growing in a controlled environment, growing leafy greens is complicated.

“Along with a more complicated SKU mix in this category in comparison to other vegetable or berry crops, it has also become a more value-added category,” Thompson says. “We have to innovate our product line and our branding as quickly as we’re producing, and we have to be able to address problems as soon as they come up.”

Fortunately, Revol Greens views itself as pioneers of sorts in greenhouse-grown leafy greens.

“It’s been a constant learning process, but we’re excited for the future,” Krieg says.

Home-Grown Nutrition Program

Earlier this year, Revol Greens announced its latest innovation: a proprietary plant-based organic lettuce nutrient source. A first in the lettuce industry for both field and greenhouse environments, the newly developed Plant Fed organic fertilizer is part of Revol’s newest line extension, which includes USDA Certified Organic Spring Mix, Green & Red Duo, and Romaine Crunch.

Considering the risks of food-borne illnesses associated with animal byproducts, Revol landed on the patent-pending new Plant Fed organic solution to further enhance the safety and integrity of its packaged lettuce.

“As with all Revol Greens products, the new plant-powered nutrient source and organic line are non-GMO,” says Marc Vergeldt, Director of Research and Development at Revol Greens. “This new organic nutrient source means that our lettuce is fed by plants. We’ve devoted years of research and testing to perfect this solution.”

Focusing on Greenhouse Varieties

Thanks to the close relationships that Revol Greens Director of Research and Development Mark Vergeldt has formed in the Netherlands, Revol Greens has a close connection to seed companies, and often gains access to numbered varieties at their earliest stages of development.

“Greenhouse-specific varieties are a fairly new space for these companies, and we help provide feedback on how they can develop and grow in a controlled environment,” Vergeldt says. In some cases, companies such as Revol Greens can even help resurrect varieties that may have been neglected by the breeder because they didn’t perform well in the field, only to learn that they could be better suited for indoor production.

The feedback Revol provides, Vice President of Sales and Marketing Brendon Krieg says, has led breeders to ramp up their focus on greenhouse vegetables.

“Many of the great tomato varieties today were bred for greenhouse production, and I think we’ll see more of this innovation and development from the seed houses in leafy greens over the next few years,” Krieg says.