Dümmen Orange Created Basewell to Save Growers Time and Money

Basewell, a novel young plant propagation system from Dümmen Orange, was introduced to the industry at California Spring Trials and received a broader audience in displays and demonstrations during Cultivate’18. After witnessing the introduction of this new innovation at industry events, and the interest around it from industry experts, Greenhouse Grower caught up with Perry Wismans, Global Head of Floriculture Innovation at Dümmen Orange, to learn all the ins and outs of Basewell, and what its future holds in the marketplace. Here’s what we found out.

A New Way of Growing

Basewell is a new product form that combines the benefits of an unrooted cutting (URC) and a rooted cutting (RC) or liner, Wismans says. Produced offshore on cuttings farms where URCs are produced and harvested, Basewell cuttings are more mature than a calloused cutting, with root development already started. Growers can stick Basewell cuttings directly into a finished container and grow them into a finished plant in a comparable time period as a liner.

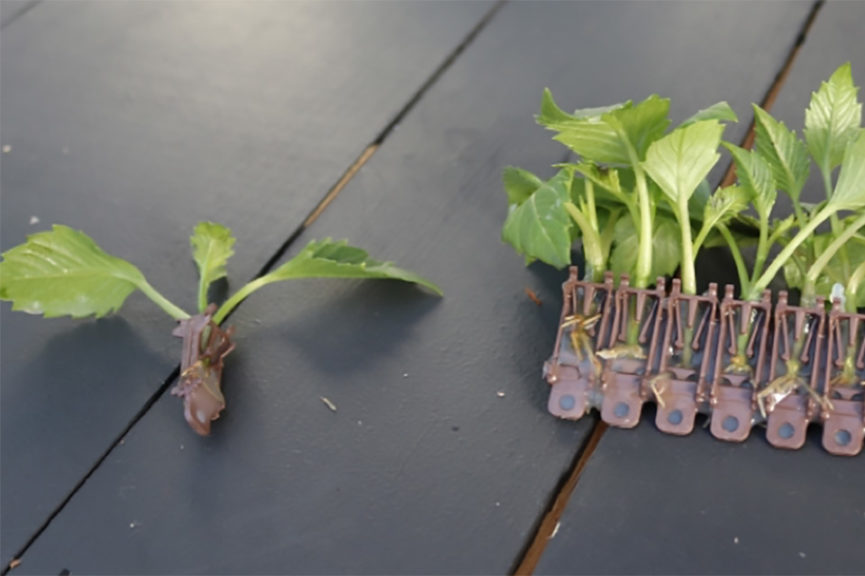

Growers can order and receive Basewell cuttings in two product forms — a Basewell Strip or a Basewell Single, depending on how they prefer to transplant. The strip is recommended for automatic transplanting by AutoStix machines from Visser, while the single is ideal for use with the ISO Cuttings Planter from ISO Group or manual transplanting by hand.

Visser’s AutoStix strip is part of the Basewell concept to offer planting efficiencies. The strip, produced from a biodegradable material, breaks down in soil 10 to 12 weeks after transplant. Dümmen Orange developed a patented gel coating applied over the strip to optimize the Basewell technology by protecting the roots during transport.

In the future, this coating will allow for additional plant protection, and rooting and other nutrient enhancements.

How Basewell Changes Things

Dümmen Orange ran a series of trials to bring the Basewell system to market, starting with proof of concept trials from January 2018 to April 2018 with several large growers and universities. These were followed by commercial trial packages in Weeks 17-19 with 281 growers in the U.S. and 21 growers in Canada.

Based on feedback from these trials, in which 58% experienced 100% success and 42% averaged a below 1% loss, Wismans says Dümmen Orange was able to conclude that the Basewell system would allow growers to simplify the process, save labor, and optimize space — here’s how:

Direct ordering and shipping: One of the promoted advantages of Basewell is that finished growers can order unrooted cuttings with roots, directly from the offshore farm, resulting in decreased order time and better flexibility in program planning. This also saves money on freight, with more cuttings able to be shipped in one order versus shipping from farm to rooting station to finished grower.

Labor: The labor-intensive process of sticking and rooting cuttings is streamlined through the Basewell Strip for AutoStix machines and the Basewell single for ISO Cuttings Planters and hand propagation.

Time and energy: Depending on the area of the country where a grower is based, the Basewell system could save a full month of energy costs by eliminating the need to heat greenhouses for propagation in the cold month of February because growers could start their Basewell cuttings up to a month after traditional unrooted cuttings. When planted at the same time as rooted cuttings/liners, Basewell cuttings had a similar production window, and grower trials showed that they took the same time to transplant compared to a rooted cutting/liner (50%), were faster to transplant (33%), or took more time than a rooted cutting/liner (17%).

“We have proven in trials that the finished time is the same as a traditional rooted cutting/liner when you have six weeks or longer crop times, such as for larger containers,” Wismans says. “When you have relatively short crop times —and you very often have that in small pots, in a six-pack or quart — then you see that Basewell will most likely need a week more because that five weeks is not sufficient time to catch up to what they are behind compared to a traditional rooted cutting. Week six is the breakeven point.”

Optimized space: Growers receive a product that they can stick directly into the finished container. By outsourcing the rooting process, growers reduce the need for expensive propagation equipment and space in the greenhouse and can use it instead for finished production.

“Rooting is the most complex process in growing — the start of the process. So when you can reliably outsource that, you bring a lot of simplicity to your greenhouse. Life becomes easier — I like to use the word stress-free,” Wismans says. “When you outsource that, you automatically create free space because the space you had for rooting you can now use for other things — put an extra turn in, start earlier, grow different products — it’s different for every grower.”

Who Benefits From Basewell?

With everything factored in, Wismans says growers can expect to see 15% to 25% savings with Basewell, compared to ordering unrooted cuttings or rooted cuttings.

“If you compared to a rooted cutting or liner, the price will be a little cheaper or most cost advantageous — purely looking at the product,” Wismans says. “There’s an additional savings in freight because this is shipped directly from the farm — growers can save 6 to 8 cents in freight versus buying a liner by truck. So they save a little bit on the product, but they save a whole lot on freight.”

Growers who propagate many of their own unrooted cuttings — typically large and mid-size growers — stand to benefit most from Basewell, Wismans says. But growers who buy large quantities of liners may also benefit from this system. The cost for Basewell cuttings will depend on the quantity ordered, and the volume of product a grower orders from Dümmen Orange.

“In principle, we have seven price levels, and they’re all based on overall volume,” Wismans says. But it doesn’t matter if you buy from level one or level seven. In relation, you always will be able to make that 15% to 25% cost savings when you relate it to your current cost structure.”

Where Can You Get Basewell Cuttings?

Because the system was invented by Dümmen Orange, for now that’s where growers can order Basewell cuttings. The first official commercial delivery season for Basewell starts in Week 40 of this year, available from Dümmen Orange cuttings farms around the world. The breeder offers a number of genera in the 2018-2019 annuals program list, from bacopa to vinca, with an added range of varieties as pinched Basewell products. Learn more about the varieties available as Basewell cuttings on the Dümmen Orange website.

Ultimately, the Basewell system could be used with nearly any species, not limited to annuals, Wismans says. Dümmen Orange is willing to license the technology to other breeders. Currently, Dümmen Orange is discussing trials of the Basewell system with other producers to see if it’s right for them. If it works out, licensing may be an option, Wismans says.

“While we would like to have 100% of a grower’s business, that’s very unlikely to happen, so for growers to long-term abandon their rooting activities, they would also need other suppliers being able to supply this product,” Wismans says. “If not, they would still need rooting facilities to operate impartially, which will be cost-inefficient.”