Minimize Build-up In Your Water Pipes

Can you identify the water problem in this case study, where overhead irrigation is staining poinsettia foliage? A brown residue formed on the outside of leaves, creating an aesthetic problem (Figure 1a, see slideshow).

The staining occurred regardless of fertilizer concentration. Lower leaves had to be manually removed or cleaned, increasing labor cost and causing delays during peak shipping. A bath-ring effect was even forming on greenhouse side walls from the overspray of irrigation booms (Figure 1b, see slideshow).

At the 20-acre facility, the labor cost to inspect, clean, and replace clogged emitters, filters, and irrigation lines was estimated at more than $148,000 annually. On opening a 2½ -inch-diameter pipe after a five-year lapse, the sludge that lined the inside greatly reduced the effective pipe area (Figure 2, see slideshow). The water mains that were cleaned by water-blasting remained free of sludge for about three years.

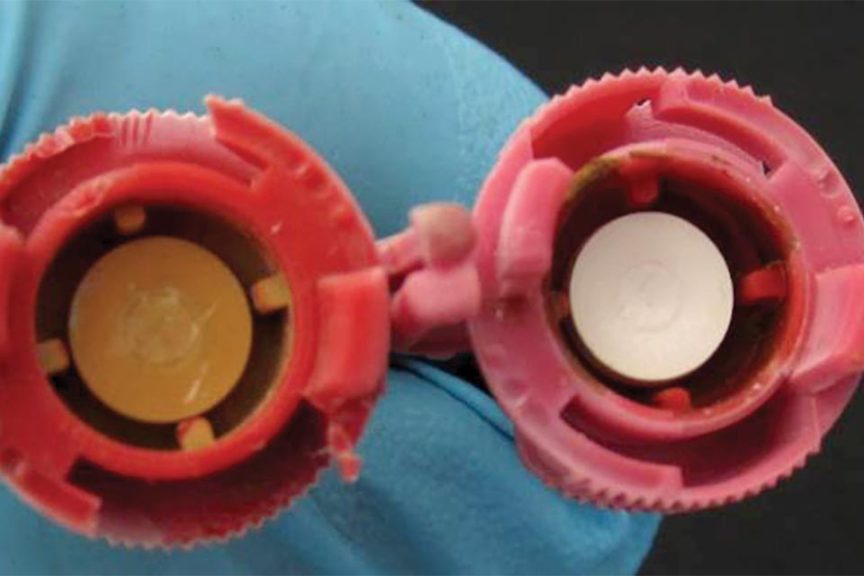

Although emitters could be cleaned in acid (Figure 3, see slideshow), the iron surrounding the rubber diaphragm was not removed, and the emitters still clogged. Some of the emitters and drip irrigation lines had to be replaced, at an additional cost of more than $4,000. The total annual cost therefore exceeded $152,000 (not including crop shrinkage and labor to remove stained leaves). A copper-ionization system being used for algae control was not controlling the issue. Something else had to be done.

Getting To The Root Of The Problem

The greenhouse was using well water, with a slightly high pH of 7.4, a low electrical conductivity of 0.1 mS/cm, and low alkalinity at 33 ppm CaCO3. A water test found that total suspended solids, a measure of particles in the water, equaled 6.2 mg/L (higher than the desired 5 mg/L limit for drip irrigation).

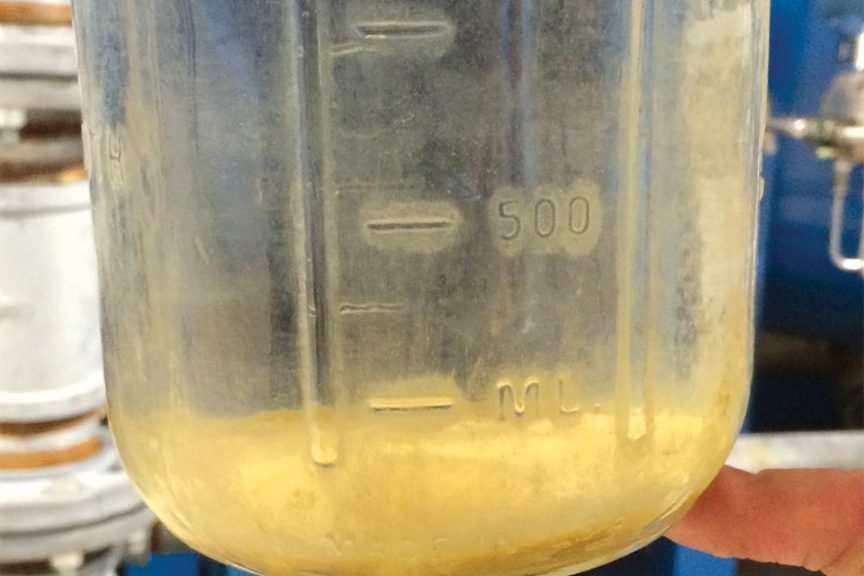

Lab analysis showed 1.3 ppm of dissolved iron. However, this iron concentration is deceivingly low, because most of the suspended iron precipitated out overnight (Figure 4, see slideshow). An iron test that was performed onsite immediately after the water came out of the well showed 8 ppm of iron.

Bacteria count in the source water was 253 colony-forming units per milliliter (CFU/mL), which increased to 573 CFU/mL at a far emitter. These levels are well below the biofilm risk level of 5,000 CFU/mL measured by plating bacteria with 3M Petrifilms.

A sludge sample from inside a pipe was sent to a commercial analytical laboratory. After dissolving the sludge in acid for analysis, the lab reported minerals including iron (58%), phosphorus (23%), calcium (11%), potassium (3%), and zinc (2%).

The Culprit: High Iron In The Irrigation Water

The problem was a mineral issue including both dissolved iron and iron particles (rust, which is iron oxide), rather than a biological problem such as iron bacteria.

The grower reached out to researchers, water treatment vendors, and another grower who faced a similar problem of high iron in well water. Given that more than 21 million gallons of water were used each year, with a flow rate of up to 400 gallons per minute, all options had a significant cost. A potassium permanganate-greensand filtration system was installed, which is a well-established technology for iron removal. Equipment and installation cost approximately $200,000. Potassium permanganate cost was $0.84/1,000 gal, or $17,640 per year. By eliminating the $152,000 annual cost from high iron, the equipment would pay back within two years.

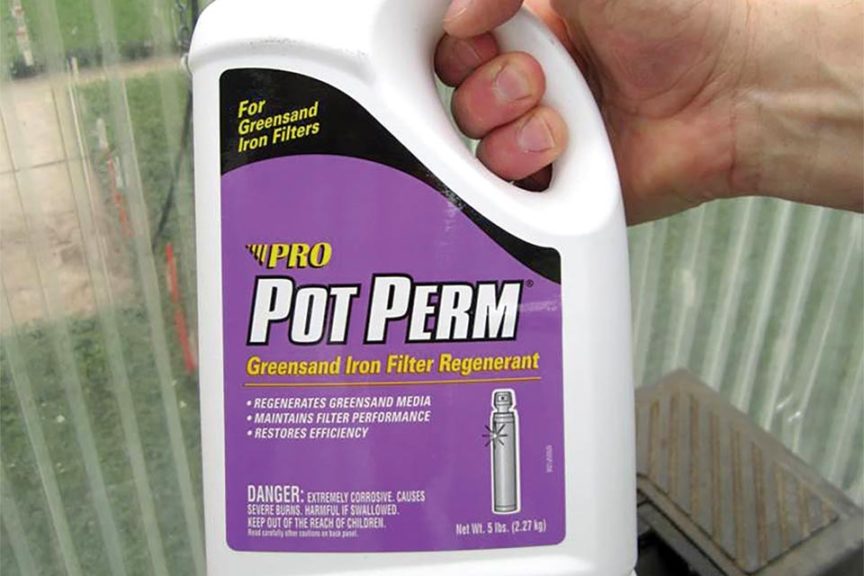

Potassium permanganate was first injected into the water to oxidize the dissolved iron (Figure 5a, see slideshow). Potassium permanganate is a low-cost oxidizer and, similar to chlorine, will irritate or burn skin if direct contact occurs. This salt is highly soluble, and solid crystal or liquid forms can be purchased that create a pink-purple solution. During treatment, the permanganate (MnO4–) is converted to solid manganese oxide (MnO2) or dissolved Mn2+, and the oxygen released in this process causes dissolved iron to oxidize and precipitate (form solids). Treatment by-products are a low concentration of potassium (a plant nutrient), along with dissolved manganese, manganese oxide, and iron oxide particles.

After potassium permanganate treatment, water passed through three 1,000-gallon filters (Figure 5b and Figure 5c, see slideshow) run in parallel to allow a 400 gallon/minute flow rate. The filters were filled with glauconite greensand, which is a naturally mined mineral that oxidizes dissolved iron and manganese on contact. The oxidized iron and manganese form small particles, which become trapped in the filter bed. Automatic back-flushing to clean the filter occurred based on pressure drop, indicating that filters were loaded with particles.

At another grower location, the greensand continued to be effective at removing iron from well water for several years, before replacement of the media was necessary (similar to procedures to replace silica sand or crushed glass in other filters). Greensand can be used to remove high iron, manganese, or hydrogen sulfide (which gives a rotten egg smell) in water.

Other approaches exist to remove iron. Oxidizers, such as chlorine, can precipitate dissolved iron. Some nursery operations inject air or pump water into a settling pond that contains an aerator, where the air converts dissolved iron to iron oxide. Water can be passed through an iron-selective resinous cation exchanger. Injection of either acid or a chelating agent can keep dissolved iron in solution.

Factors to select between technologies include the concentrations of dissolved, organic, or particulate iron, the water pH, and other dissolved ions. Work with a water treatment expert who has experience with multiple technologies, in order to decide which approach is the best match for your water quality and needs.

Thanks to funding support and collaboration from industry partners the Floriculture Research Alliance (FloricultureAlliance.org). This case study is part of the Clean WateR3 research project funded through the USDA-NIFA Specialty Crops Research Initiative. For more information, see CleanWateR3.org.

In Case You Missed It

Unclog Drip Emitters In Your Greenhouse

Pinpoint Toxicity in Pond Water