Using Bench Top Heating With Reduced Air Temperature During Poinsettia Cold Finish

Holiday poinsettias remain a staple symbol of the holiday season and the second-most valuable potted plant produced in the U.S. As fuel costs have risen, the wholesale price of poinsettias has not kept up, thus threatening the profitability of producing this crop for some growers. If a higher price cannot be sustained in certain markets, then new growing methods to lower production costs will need to be employed.

One strategy to reduce heating costs during poinsettia production is to reduce temperatures during finishing (RTF). This is often referred to as cool- or cold-finishing. Previous research at Purdue University and the University of New Hampshire suggests that air temperature set points during finishing can be lowered to 68°F/56°F or 70°F/62°F for certain cultivars. While this is a good method for reducing energy costs, RTF can cause some adverse effects on plant quality, such as reduced growth and bract area, as well as delayed development.

We postulate that RTF in combination with bench-top root-zone heating could allow for production of high-quality poinsettias at even lower air temperatures without a significant delay in crop timing (time to marketable). This production method could therefore allow growers to lower production costs even further and increase profit margins for producing poinsettias.

[blackoutgallery id=”123680″]

How This Study Was Conducted

Plant material and culture. Previous studies determined that poinsettia cultivars with early response attributes, moderate to high vigor and naturally large bracts were most suitable for RTF. We selected six red poinsettia cultivars with these characteristics. Rooted cuttings of poinsettia ‘Prestige Early Red,’ ‘Prestige Red,’ ‘Premium Red,’ ‘Infinity Red,’ ‘Viking Red’ and ‘Bravo Bright Red’ were received at Purdue University on week 32 (August 6) and transplanted into 6-inch plastic azalea pots on week 33 (August 11) using a soilless substrate consisting of 65 percent peat, 20 percent perlite and 15 percent vermiculite.

Greenhouse environment and temperature treatments. Plants were grown under a 16-hour long-day photoperiod consisting of natural day lengths with day-extension lighting from high-pressure sodium (HPS) lamps until week 40 (October 1). Day/night air temperature was maintained at 75°F/66°F, for an average daily temperature (ADT) of 70.5°F, until week 42 (October 15). On October 15, RTF was employed and the air temperature was reduced to 66°F/55°F (8-hour day/16-hour night) for an ADT of 59°F.

Plants were placed on benches without root-zone heating (RZH) or with RZH set points of 70°F, 75°F or 80°F; or moved to a greenhouse without RZH and an ADT of 70°F (commercial control). Root-zone temperatures were achieved using bench-top rubber tubing with circulating 120°F water, with each bench individually controlled by a substrate temperature probe. Plants were placed into shuttle trays, which sat directly on the rubber tubing on the bench (Figure 1, see slideshow).

Can We Overcome The Delay?

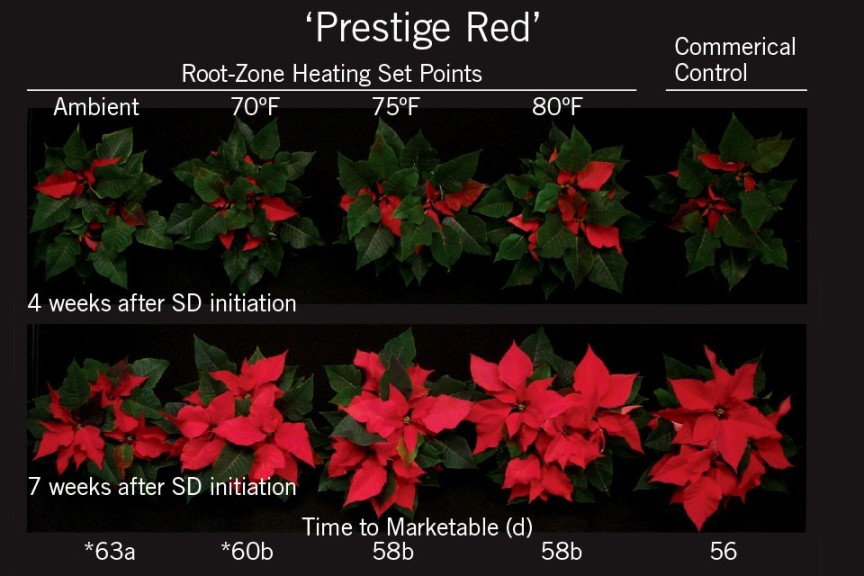

We found that all cultivars finished at an ADT of 59°F on benches with RZH 75°F or warmer had no significant delay in time to marketable, compared to the commercial-control plants finished in a greenhouse with an ADT of 70°F. Plants were described as marketable when all bracts were fully colored, exhibiting full rings of red. This conclusion indicates that, as expected, the delay in flowering that is observed when using RTF can be overcome by use of bench-top root-zone heating.

Also, as root-zone temperature increased, time to marketable and time to anthesis (when pollen shed was visible on at least one flowering branch) decreased. For example, we observed that time to marketable was reduced by 5, 5 and 3 days, respectively, for ‘Premium Red,’ ‘Bravo Bright Red’ and ‘Infinity Red,’ when plants were finished on a RZH set point of 80°F compared to a RZH set point of 70°F. This indicates that desired time to market can be controlled by adjusting root-zone temperature set-points.

All cultivars took significantly longer to reach marketable when grown under the ambient RTF (no RZH) compared to the commercial control. An example of this is shown in Figure 2 (see slideshow), as ‘Prestige Red’ plants were delayed by seven days. Some cultivars were not even marketable by week 50 (December 10) and were of low quality when grown at ADT of 59°F without root-zone heating, demonstrating the importance of using root-zone heating when air temperatures are further reduced from the recommended 68°F/56°F.

Our results indicate that when air temperatures are reduced to 66°F/55°F and a RZH set point of 75°F to 80°F is employed, a grower can still produce a poinsettia crop by target market dates without starting the crop earlier than week 31 or 32.

How Does Quality Compare?

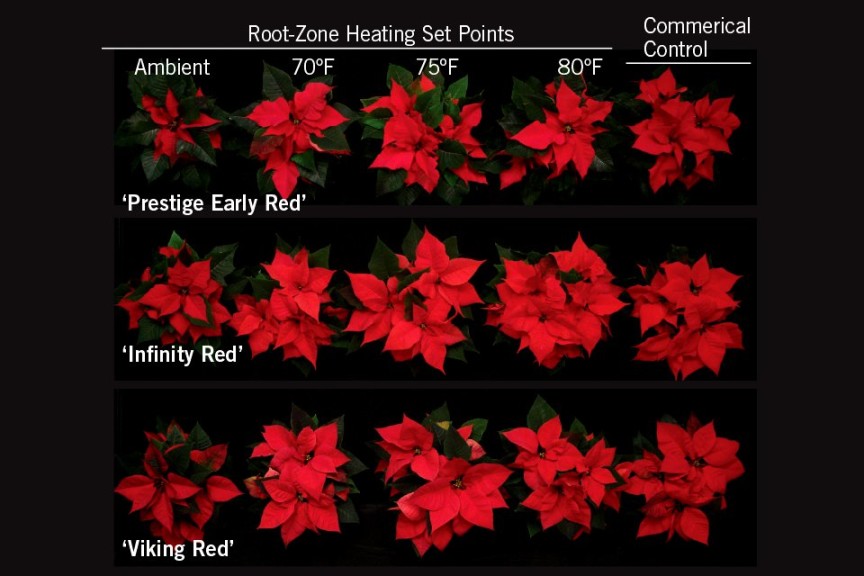

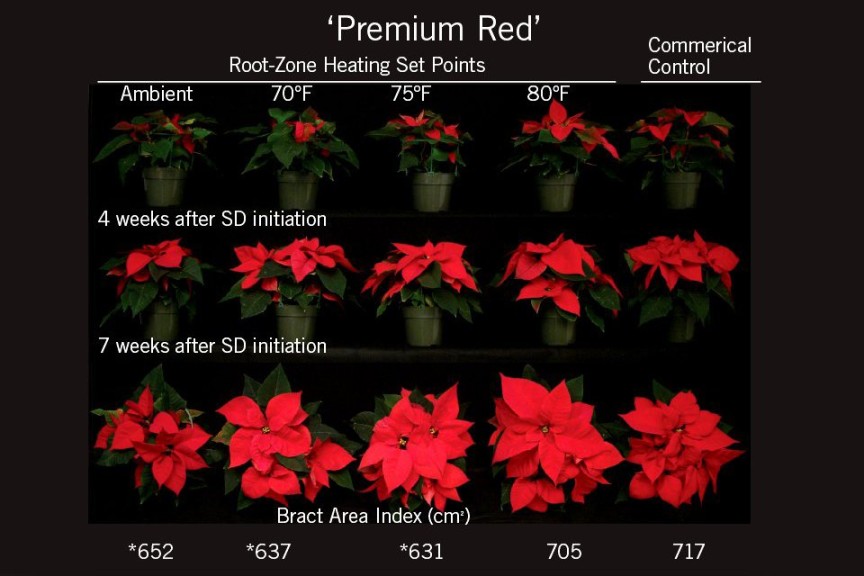

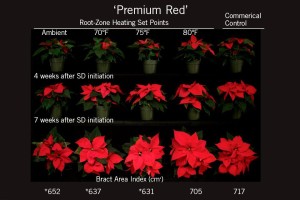

High-quality poinsettias were obtained when plants were finished under RTF with a RZH set point of 75°F or higher (Figure 3, see slideshow). Bract area index (BAI) of the crop was determined in this study by measuring the two largest bract rings and using the formula for an ellipse [(widest diameter × perpendicular diameter × π)/4]. The two were then averaged together to determine the BAI.

Past studies have shown a decrease in BAI under RTF. While we did observe an increase in BAI with increasing root-zone temperature, results were variable. Only ‘Premium Red’ and ‘Bravo Bright Red’ had similar BAI to the commercial control when grown on RZH set points of 80°F and 75°F to 80°F, respectively (Figure 4, see slideshow). This decrease in BAI did not necessarily describe the redness of the plant, though.

While plants in the commercial control greenhouse may have had larger bracts, we also noticed that there were fewer visible large bracts. Plants finished under reduced air temperatures tended to have smaller bracts, but they were more visible, which resulted in a similar level of overall redness. Therefore, root-zone heating can help with some of the adverse effects on bract area associated with RTF.

Most cultivars grown on RZH temperatures of 75°F or 80°F were taller when we deemed them marketable compared to plants grown without RZH. However, stem elongation was cultivar dependent. For instance, there were no differences in the height of ‘Viking Red’ plants between treatments, while all ‘Premium Red’ plants were significantly shorter under reduced finishing temperatures. Though these variable effects were not of great practical significance to growers. Overall, root-zone heating promoted enough stem elongation to meet target market heights for most cultivars when finished under a reduced air temperature.

Grower Recommendations

Based on our findings, we suggest that growers conduct their own trials and target root-zone heating set points of 75°F to 80°F in combination with reduced air temperatures during poinsettia finishing. This production regime has been shown to produce high-quality poinsettias in our northern latitude study with reduced energy input for heating and use of plant growth regulators.

Rather than excessively heating the greenhouse air, the heat from RZH is delivered straight to the plant, where it is needed. Root-zone heating creates a microclimate at plant level, raising both canopy and plant temperature, therefore allowing for an increased rate of development and growth even when the air temperatures are reduced.

Hence, using root-zone heating when cold finishing poinsettias allows you to further reduce your air temperature set points without a significant delay in crop timing or decreased bract area and growth. Now that we know this is a plausible method of poinsettia finishing, the precise energy and cost savings will need to be explored in further detail in future studies.