Bench-Top Root Zone Heating: Can You Reduce Air Temperatures And Finish Bedding Plants On Time?

In the July issue of Greenhouse Grower, we discussed the effects of transplant date and the use of a row cover on cold-tolerant bedding plants grown in high tunnels, compared to conventionally heated greenhouses . In this article, we highlight another energy-efficient strategy: using bench-top root zone heating in combination with reduced air temperatures to finish bedding plants.

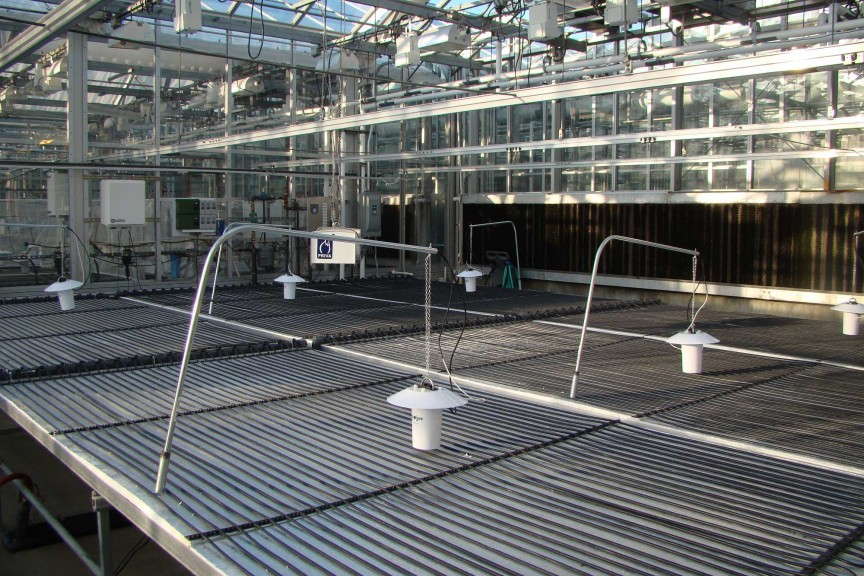

Soil, floor and bench-top root zone heating systems are by no means new technologies. In fact, the use of root zone heating dates back to as early as the 1970s. Bench-top root zone heating systems generally consist of a boiler or hot water heater, circulating pumps, distribution piping and thermostat controls (Figure 1). While these technologies were developed approximately 40 years ago, a survey conducted in 2008 revealed that only 7 percent of growers were using root zone heating.

Several studies conducted in the 80s and 90s stated that energy savings up to 50 percent could be achieved by using root zone heating in combination with reduced air temperatures, compared to perimeter hot water heating. However, a majority of those studies were conducted on cultivars that are no longer commercially available. To our knowledge, research-based information about specific combinations of air and root zone temperatures for several commercially important bedding plant species grown today is not currently available. Therefore, the objective of this study was to evaluate the effectiveness of root zone heating, in combination with reduced air temperatures, on the growth and development of nine commercially important bedding plant species with different cold tolerance classifications.

[blackoutgallery id=”61894″]

How This Study Was Conducted

Plant Material and Culture: Plugs or liners of cold-tolerant petunia ‘Dreams Midnight,’ pansy ‘Matrix Yellow,’ French marigold ‘Durango Bee,’ snapdragon ‘Oh Snap Pink’ and osteospermum ‘Serenity Bronze’; cold-intermediate seed impatiens ‘Super Elfin Lipstick’ and verbena ‘Aztec Blue Velvet’; and cold-sensitive: New Guinea impatiens ‘Celebration Red’ and vinca ‘Pacifica XP Rose Halo’ were received at Purdue University from a commercial greenhouse propagator (Tagawa Greenhouses, Inc.). Refer to our Basics and Beyond article on base temperatures in the July issue of Greenhouse Grower for more information about the cold-tolerance classifications.

Upon arrival, plants from each species were transplanted into 4.5-inch round containers filled with substrate comprised of 65 percent Canadian sphagnum peat moss, 20 percent perlite and 15 percent vermiculite. Plants were fertilized once a week with clear water supplemented with a water-soluble fertilizer (WSF), providing 400 ppm N.

Between each fertigation, plants were irrigated as necessary with acidified clear water, and leaching was kept to a minimum. The weekly application of a high-rate fertilizer was used to reduce any confounding variables that could have been associated with treatments receiving different rates of fertilizer, as a result of substrates drying out faster under higher root zone temperatures.

Greenhouse Environment: Plants were grown in two glass-glazed greenhouses with exhaust fan and evaporative-pad cooling and radiant hot water heating, controlled by an environmental computer. The photoperiod was a constant 16 hours, consisting of natural daylengths with day-extension lighting provided by high-pressure sodium lamps (HPS), which also delivered supplemental lighting to achieve a daily light integral (DLI) of 10 to 12 mol∙m–2∙d–1.

Temperature Treatments: The greenhouse air temperature set point was a constant 60°F for plants receiving root zone heating. Substrate temperature set points of 65°F, 70°F, 75°F and 80°F were achieved using independently programmable sections of bench-top tubing that circulated hot water from a high efficiency electric boiler (Figure 1), with an ambient treatment receiving no root zone heating serving as a control.

A separate greenhouse was used as a commercial control with a day/night air temperature set point of (12h/12h) 68°F/65°F and no root zone heating. Ten plants of each species were randomly selected, spaced equally in trays and placed on benches with or without root zone heating.

Can You Finish On Time?

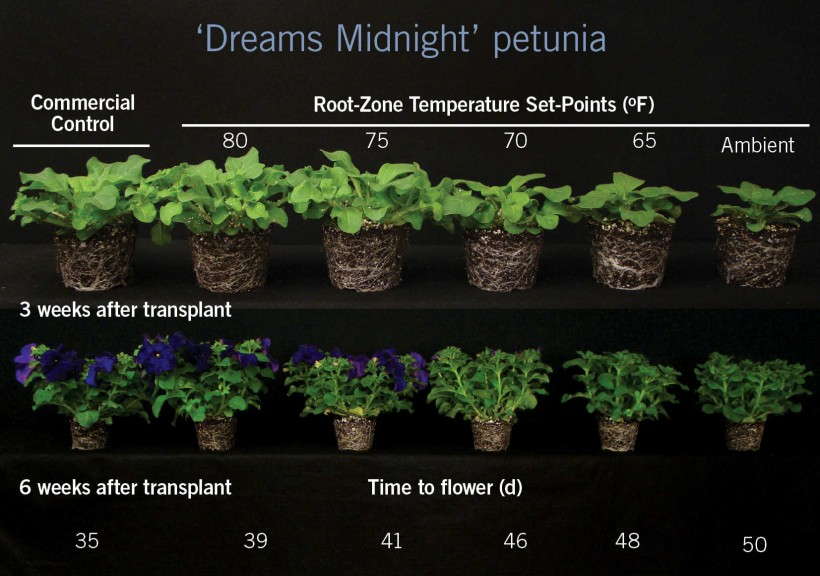

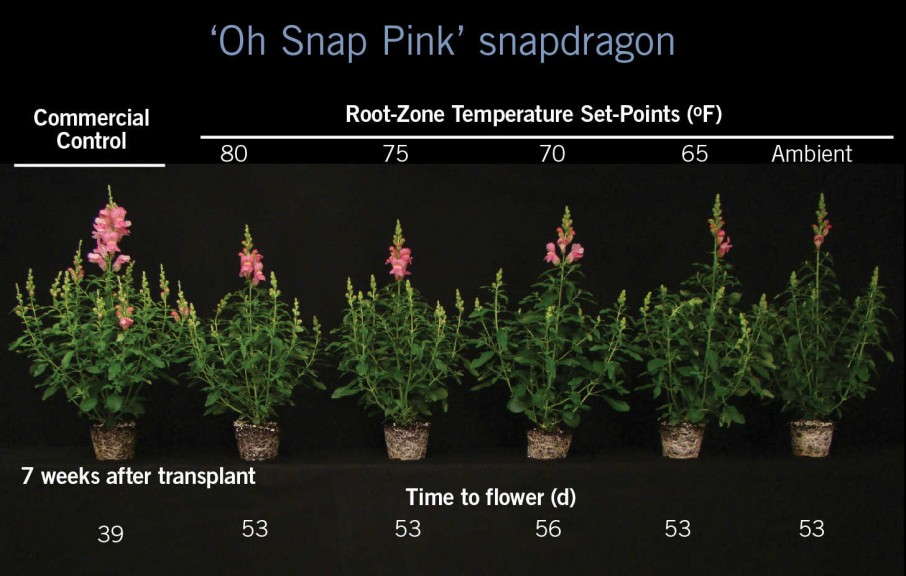

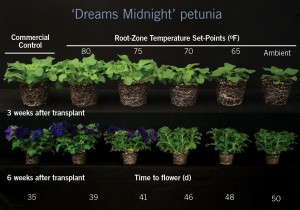

Our results indicate that the time from transplant to first open flower of plants placed on root zone heating varies by species and cold-tolerance. For example, time to flower for petunia was delayed by 15, 13, 11, 6 and 4 days, respectively, as root zone temperature increased from 60°F to 80°F with an air temperature of 60°F, when compared to the commercial control with day/night air temperatures of 68°F/65°F (Figure 2). The delay in time to flower for most of the cold-tolerant species was minimal when they were grown on bench tops with root zone temperatures of 75°F or 80°F and an air temperature of 60°F.

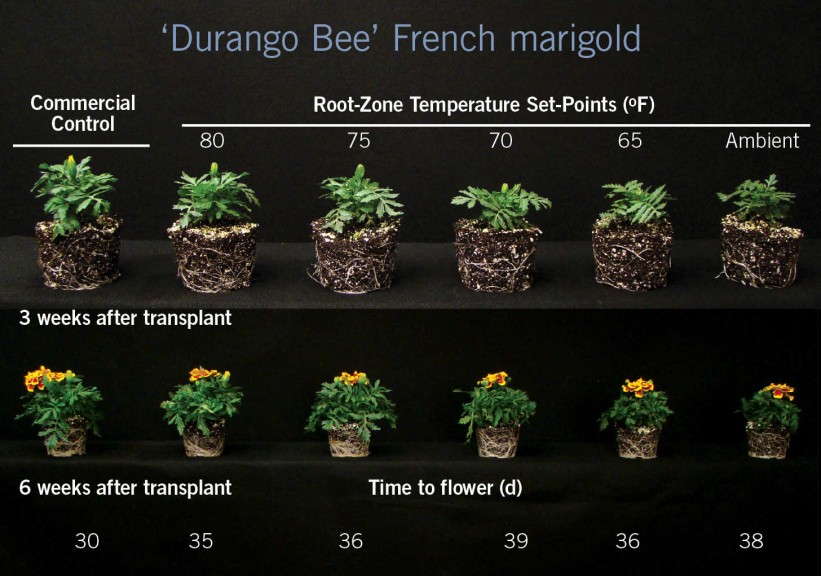

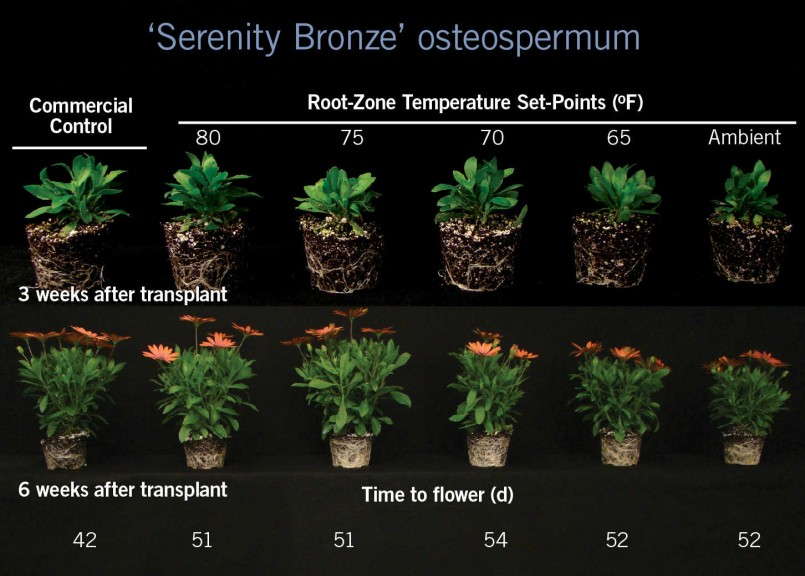

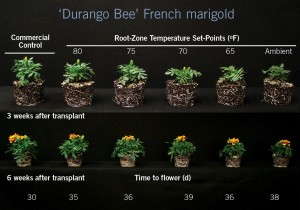

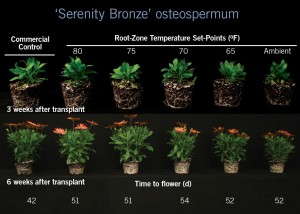

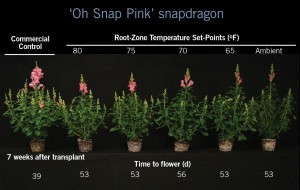

For example, French marigold showed a 6- and 5-day delay and pansy showed a 6- and 1-day delay, respectively (Figure 3). However, time to flower of cold-tolerant snapdragon and osteospermum was delayed by 9 and 14 days, respectively, at root zone temperatures of 75°F and 80°F (Figures 4 and 5). As expected, time to flower of cold-sensitive New Guinea impatiens and vinca was significantly delayed with root zone heating. Additionally, chilling injury made the New Guinea impatiens unmarketable.

Shoot tip temperature primarily controls the rate of development (i.e., leaf unfolding rate, days to first open flower) and, to a lesser degree, substrate temperature. Therefore, we postulate that species that have a prostrate or shorter growth habit are best suited for root zone heating production.

Our results indicate that cold-tolerant petunia and French marigold can be produced with limited delay in flowering time, while maintaining quality, compared to the commercial control if root zone temperatures of 75°F or 80°F are achieved with a reduced air temperature of 60°F.

What About Energy Savings?

We used USDA’s Virtual Grower software to estimate potential energy savings a grower may achieve by producing a petunia crop in a double poly greenhouse located in Indianapolis, Ind., with a projected market date of March, 10, April 10 and May 10.

It estimated that a grower could reduce heating costs by 20 percent, 16 percent and 15 percent, respectively, by reducing the air temperature from 68°F/65°F to a constant 60°F with an added four days of production. These estimates are reduced for every day the crop is delayed. At a certain point, any savings that could be achieved by lowering the air temperature will be negated and eventually will require more energy.

If we were only considering the cost to grow under reduced air temperatures, the energy savings may be high enough for a grower to consider installing a bench-top root zone heating system. However, growers must consider the other costs associated with using root zone heating in combination with reduced air temperatures, such as the expense of operating a boiler or hot water heater. Unfortunately, with our system, we were unable to quantify the amount of energy that would be necessary to operate our boiler to heat the root zone to 75°F or 80°F.

The energy used to run a boiler or hot water heater to heat the root zone would reduce the 15 to 20 percent savings, not to mention the additional cost to install the system and potential return on investment. However, for growers who already have root zone heating systems installed, this study may give you a better idea of the substrate temperatures needed to grow bedding plants under reduced air temperatures. This study may also help growers who already have a system installed, select crops that respond positively and avoid crops that we found to not benefit from root zone heating.

The authors thank Ball Horticultural Co., Everris, Fafard and the Indiana State Department of Agriculture Specialty Crop Block Grant 205749 for supporting this research.