UbiGro Aims for Innovation in How Growers Optimize Sunlight

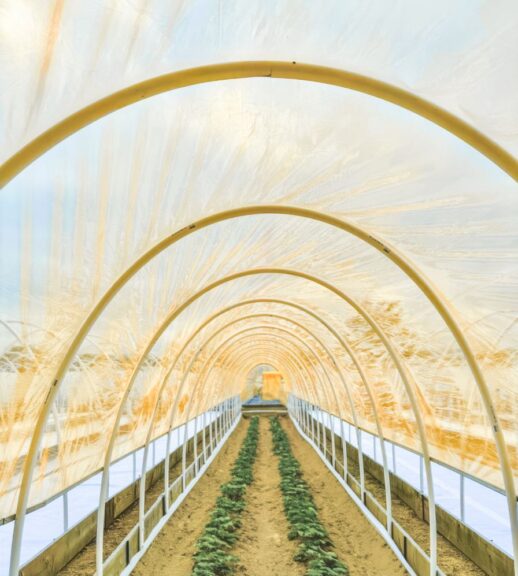

UbiGro films were installed and tested in a hydroponic greenhouse located at Growing Opportunities Farm in Alcalde, NM. In this five-month plant trial, two sections of UbiGro films were suspended over a row of 126 beefsteak tomato plants. The tomato production under these films was compared to a control row located in the same greenhouse that was only exposed to un-modified sunlight. There were three rows of tomatoes in between the two test rows, which served as barrier rows, ensuring the light conditions for the film and control row were distinct. The 30-foot by 90-foot greenhouse had a double polyethylene cover that was whitewashed to lower light intensity during the summer.

Yield enhancement was consistently observed throughout the duration of the trial. This resulted in a +20.5% overall increase in fresh weight harvested under the UbiGro films relative to the control. The benefit was most pronounced in high-light level months of June and July. There were no observed differences in color, flavor, or overall quality of the fruit harvested from the two separate rows of tomatoes.

Films were tested for stability regularly throughout the plant trial, and the relative luminescent quantum yield, or photon conversion efficiency, was compared. The quantum yield of the film correlates with the brightness of the emission, and therefore indicates the performance of the film over time. Over the course of the five-month summer trial, the UbiGro films showed no degradation in quantum yield, indicating no change in the optical properties of the film. The films have remained installed in the greenhouse for an additional 77 days and the film has maintained its original optical performance.

How It Works

UbiGro glows when illuminated with sunlight. Unlike shade cloths, spray coatings or colored films that filter light, the technology converts short-wavelength photons (blue and UV) to longer wavelength photons (orange and red).

As a luminescent layer, the high-tech, Nobel Prize winning quantum dot technology within UbiGro empowers growers to optimize the sunlight in their greenhouse by converting excess photons of the solar spectrum while preserving colors critical for plant development.

UbiGro empowers greenhouse growers to control light quality, allowing plants to get the most from the world’s biggest light source: the sun. Enabled by patented quantum dot technology, UbiGro uses fluorescence to increase photosynthetic efficiency to improve fruit and flower production without wires or electricity. This increases crop yields for the grower, which means more revenue for the farm all without supplemental greenhouse lighting.

A more uniform distribution of sunlight throughout the greenhouse canopy will increase overall photosynthesis and production. Diffuse scattering of sunlight is an effective way to achieve a more uniform distribution.

Direct light from the sun is strongly absorbed by the upper canopy leaving the lower canopy shaded. Diffused light avoids this issue: there is less shading by the upper canopy, higher light levels in the lower canopy, and the net result is better overall crop growth and plant productivity.

What is light diffusion? Simply put, it is the scattering of light. Photons from the sun get scattered in all directions as they pass through our layer of quantum dots. Much like the dimpled reflector of an HID grow light that scatters the photons of light from the bulb, UbiGro film scatters photons from the sun.

The quantum dots used by UbiGro have great diffusion properties and when sunlight passes through UbiGro, these photons are not only having their wavelength changed to be more orange and red but also scattering them, making them penetrate deeper into the plant canopy to increase overall production.

Learn more in the slideshow above.