Reduce Flowering Time

This is the second article in a two-part series looking at the effects of light during cutting propagation. While the first article focused on the effects of daily light integral (DLI) during propagation of rooted cuttings, this article will focus on finished plants. We wanted to see how DLI during propagation affected growth and flowering after transplant, as well as identify how the DLI during propagation interacted with the DLI during finishing to influence crop timing and quality.

Study 1: Lighting During Propagation

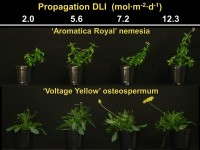

Cuttings of Angelonia ‘AngelFace White,’ Nemesia ‘Aromatica Royal,’ Osteospermum ‘Voltage Yellow,’ and Verbena ‘Aztec Violet’ were stuck in 105-cell trays and placed in a propagation greenhouse with an air and substrate temperature set point of 73°F and the average DLI was maintained at about 5 mol•m¯²•d¯¹. After seven days, cuttings were placed under a range of DLIs, from 1.2 to 12.3 mol•m¯²•d¯¹, achieved using supplemental light from high-pressure sodium (HPS) lamps and no shade or shade cloth providing 31 percent, 68 percent or 86 percent shade.

In order to identify any residual effects of propagation DLI on subsequent growth and development during finishing, cuttings from the various propagation DLI treatments were transplanted and grown in a common environment.

Two weeks after cuttings were placed under the propagation DLI treatments, cuttings were transplanted into 4.5-inch containers filled with a commercial soilless substrate. Plants were grown in a greenhouse with an air temperature set point of 70ºF and an average DLI of about 12 mol•m¯²•d¯¹ and fertilized with 200 ppm N from a balanced fertilizer at each watering. When the first flower opened on a plant, we collected data including time to flower from transplant, flower bud and branch number, plant height and shoot dry weight.

Study 2: Lighting During Propagation And Finish

In a separate study, cuttings of Angelonia ‘AngelMist White Cloud,’ Nemesia ‘Aromatica Royal,’ Osteospermum ‘Voltage Yellow,’ and Verbena ‘Aztec Violet’ were stuck in 105-cell trays and placed in a propagation greenhouse with an air and substrate temperature set point of 73°F and the average DLI was maintained at about 5 mol•m¯²•d¯¹. After seven days of callusing, cuttings of each species were placed under one of three propagation DLIs, achieved as previously described using different shade cloths and supplemental lighting.

After two weeks under the DLI treatments, cuttings from each propagation DLI were transplanted and placed in a greenhouse under one of three DLI treatments for finishing. The different finishing DLIs were achieved similar to those in the propagation environment — with the use of no shade cloth or varying levels of shade cloth and supplemental light from high-pressure sodium (HPS) lamps. This resulted in nine unique combinations of propagation and finishing DLI treatments. As with the cuttings study, when the first flower opened on a plant, we collected data including time to flower from transplant, flower bud and branch number, plant height and shoot dry weight.

Summary Of Results:Lighting During Propagation Study

The number of days from transplant to flowering decreased as propagation DLI increased for all four species in this study (Fig. 1). For example, time to flower was reduced by 23 and 19 days for angelonia and osteospermum, respectively, as DLI during propagation increased from 1.2 to 12.3 mol•m¯²•d¯¹. Neither the number of nodes below the first open flower nor flower buds for angelonia, nemesia and verbena were influenced by propagation, indicating that flowers had initiated before propagation began. With the development of cultivars that are less photoperiodic, controlling the flowering of free-flowering cultivars is a new challenge growers are facing.

The DLI during propagation also affected shoot growth, plant height or stem length, and the number of branches at flowering. Shoot dry weight of all species decreased as propagation DLI increased. Similarly, the number of branches for several species decreased with higher DLIs during propagation. As DLI during propagation increased from 1.2 to 12.3 mol•m¯²•d¯¹, plant height of angelonia and osteospermum at flowering decreased by 2.5 and 1.5 inches, respectively, while stem length of verbena was an exception to this trend and was unaffected by DLI. For cuttings propagated under higher DLIs, the reduction in shoot dry weight and branching at flowering may be related to the faster flowering. When plants flower more quickly, there is less time to “bulk up” shoot growth and allow branches to develop.

Summary of Results: Lighting During Propagation And Finish Study

Similar to our first study, the time to flowering for all species decreased as propagation and finishing DLIs increased (Figs. 2 and 3). For example, as propagation DLI increased from 1.5 to 16.8 mol•m¯²•d¯¹ and finishing DLI increased from 4.6 to 17.5 mol•m¯²•d¯¹, the time to flower after transplant for angelonia, nemesia, osteospermum and verbena decreased by 26, 46, 25 and 26 days, respectively. Similarly, both propagation and finishing DLIs influenced flower bud number. The number of flower buds of angelonia, nemesia, osteospermum and verbena increased as both propagation and finishing DLI increased. Generally, though DLIs during both stages influenced the time to flowering and flower bud number, propagation DLI appeared to have a greater influence on time to flower while the finishing DLI had a greater influence on flower bud number.

The DLI during propagation also interacted with finishing DLI to affect the growth of angelonia, nemesia, osteospermum and verbena. While shoot dry mass at flowering for species decreased with propagation DLI, shoot mass increased with finishing DLI. However, the finishing DLI resulted in a greater increase in shoot mass for cuttings propagated under lower DLIs compared to cuttings propagated under higher DLIs. Again, this relationship between shoot mass and propagation and finishing DLIs is most likely related to the time to flower.

Height was influenced differently by propagation and finishing DLI among species. For example, the height of nemesia decreased by nearly 60 percent as both propagation and finishing DLIs increased from 2.0 to 16.8 mol•m¯²•d¯¹ and 2.0 to 17.5 mol•m¯²•d¯¹, respectively. Alternatively, height of angelonia and osteospermum were relatively unaffected by propagation and finishing DLI.

The influence of propagation DLI and finish DLI on branch number varied among species. For example, angelonia propagated and finished under low DLIs averaged no branches, while plants propagated and finished under higher DLIs had 4 branches. While both propagation and finishing DLI influenced branch number, the DLI during finishing had a stronger impact.

Economics Of Supplemental Lighting

Lighting during propagation may save you money by reducing the finishing time for plants and, as in our previous article, we will use Virtual Grower to demonstrate this. Angelonia cuttings propagated under 5 mol•m¯²•d¯¹ will finish in 32 days, while angelonia propagated under 10 mol•m¯²•d¯¹ will finish nine days earlier. The energy costs during finishing for angelonia in a 1-acre glass-glazed greenhouse with a 70°F air temperature in Indianapolis, Ind., in March would be $0.58/ft² and $0.42/ft² for cuttings propagated under 5 and 10 mol•m¯²•d¯¹, respectively. Therefore, lighting during propagation could potentially reduce finishing energy costs by 27 percent.

In addition to potential energy savings, let’s take a look at the efficiency of lighting during propagation versus finishing. For a 105-cell tray, there are about 76 cuttings per ft², whereas a square foot of 4-inch pots may have from four plants per ft² (spaced on 6-inch centers) to nine plants per ft² (spaced pot-to-pot). Therefore, a square foot of illuminated bench space in propagation can have from 844 to 1,900 percent more plants under light compared to during finishing! Furthermore, propagation areas are generally a fraction of the total production area for growers who propagate in-house, meaning a lower initial investment to light your propagation area.

The Take-Home Message

Our studies show that DLI during propagation and finishing of bedding plants clearly impacts the growth, timing and quality of finished annuals. However, our studies also demonstrate that DLI during propagation and finishing affect finished plants differently. For example, propagation DLI appears to have a stronger effect on the time to flower, while finishing DLI has a stronger effect on flower bud number and shoot dry weight.

When the energy savings during finishing and of lighting propagation space are taken together, using supplemental light may be considered a “low-hanging fruit” when looking at ways to reduce crop time and increase finished plant quality. Growers will need to evaluate their goals and priorities when making management decisions related to investing in supplemental lighting.