A New Strategy for Preventing Mold Development on Greenhouse Plastics

Polytunnels are designed to offer optimized conditions for cultivation, with warm temperatures, enhanced light levels, high humidity, and protection from the elements. Unfortunately, these humid and moist environments allow more than just plants to flourish; many microorganisms also thrive, and mold growth is a common and expensive challenge for growers. Microbes can proliferate on the polymeric plastic structures themselves – including the covering sheets and films – and their growth can lead to staining, discoloration, and product deterioration.

Polytunnels are designed to offer optimized conditions for cultivation, with warm temperatures, enhanced light levels, high humidity, and protection from the elements. Unfortunately, these humid and moist environments allow more than just plants to flourish; many microorganisms also thrive, and mold growth is a common and expensive challenge for growers. Microbes can proliferate on the polymeric plastic structures themselves – including the covering sheets and films – and their growth can lead to staining, discoloration, and product deterioration.

Furthermore, an important feature of polytunnel films is the transparent nature of the coverings, allowing transmittance of sunlight for photosynthetic plant growth. Mold proliferation can lower the film clarity, hindering UV light penetration and negatively impacting crop health. Ultimately, this causes early disposal and replacement of components that end up in landfill, further contributing to the large amounts of plastic waste generated by the agricultural sector – between 2 and 6.5 million tons annually. The development of new strategies to tackle this issue is critical to improving the industry’s green credentials, and antifungal technologies represent an interesting solution.

The Solution to a Throwaway Agricultural Sector

The demand to increase agricultural productivity and feed a growing global population highlights the necessity for polytunnels constructed with plastic materials that are treated to exhibit enhanced durability, UV stability, and light transmission. One approach is to integrate antifungal protection into the polytunnel infrastructure at the point of manufacture, providing built-in protection for polymeric structures. These antifungal solutions work for the entirety of the product’s lifetime, and do not need continuous reapplication. By preventing early product deterioration caused by fungal growth, this approach can help to extend the lifespan of structural polymer films and sheets, reducing the considerable plastic waste generated by agriculture. To further align with environmental concerns and sustainability initiatives, metal-free antifungal agents with improved toxicology profiles are preferable to the additives currently widely used in the plastics industry. Some manufacturers continue to use carcinogenic, mutagenic, and reprotoxic additives, including arsenic-based formulations.

Metal-free Protection

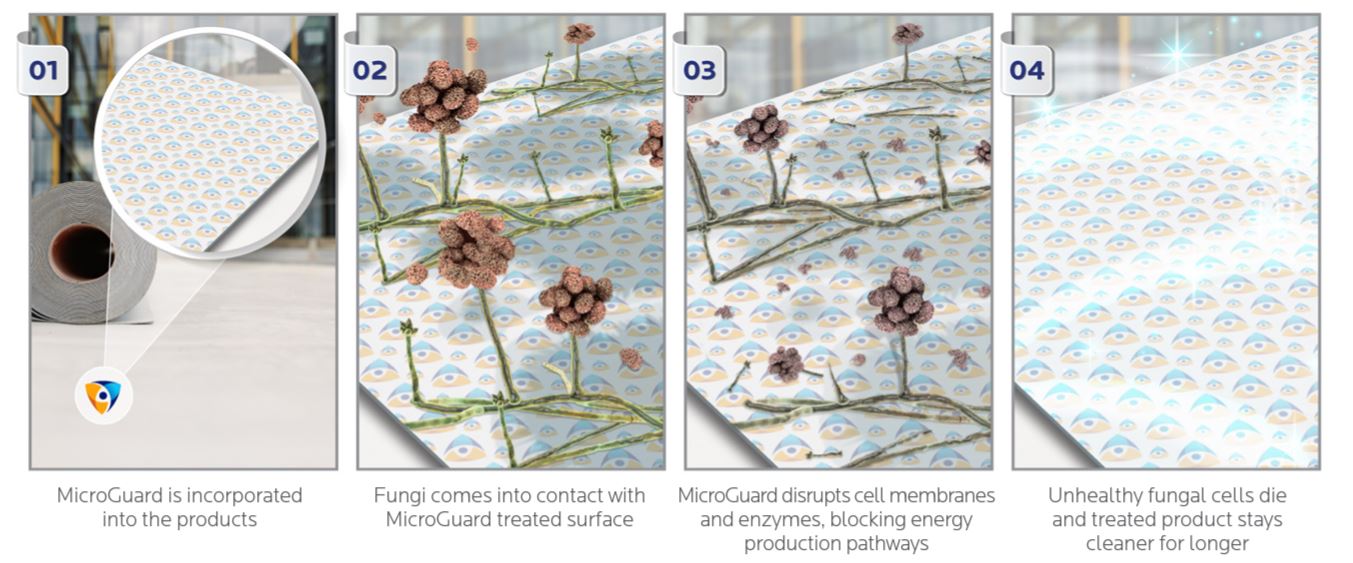

A recently developed family of metal-free antifungals for thermoplastics is well suited to polytunnel applications, imparting effective antimicrobial protection. This powerful group of antifungal agents inhibit fungal growth by suppressing cell microtubule assembly and impairing cell division, as well as disrupting enzyme production and blocking energy generation pathways to ultimately cause cell death. The inhibition of fungal growth leads to cleaner polytunnel interiors and longer lifespans for plastic components.

The efficacy of two different liquid formulations of metal-free antifungals integrated into PVC plaques was qualitatively tested using the AATCC TM 30-III method – against Aspergillus niger – and the ASTM G21 method, against a mixture of five different fungal species. All treated plaques received scores corresponding to zero fungal growth observed on both tests, while the untreated controls showed macroscopic and heavy fungal growth, respectively. This full inhibition of fungal growth was also seen when the ASTM G21 test was repeated under simulated outdoor UV light conditions.

Multipronged Approaches for Maximum Sustainability

A range of management strategies is required to effectively manage harmful microbes and improve agricultural productivity. The incorporation of antifungal technologies into polymeric structural components of polytunnels can play a key role in a multipronged approach, and it is likely that future industry recommendations for polytunnels will include antifungal interiors and surfaces. Polytunnel structures with built-in antifungal technologies require less maintenance compared to those without it, and the technology minimizes the need for frequent cleaning, saving time and resources for growers. It also reduces the risk of damage to the polymer material that may occur during aggressive cleaning practices, preventing premature disposal and replacement.

Polytunnel structures are susceptible to fungal surface growth on numerous polymeric components, leading to structural damage and limited UV transparency, preventing much-needed sunlight from reaching crops. Built-in antifungal solutions can provide continuous protection for plastic components, preventing staining, discoloration and degradation to improve the durability, longevity and aesthetics of the polytunnel structures, reducing the need for frequent replacement or parts. This can result in decreased plastic waste entering landfills, contributing to overall sustainability efforts in the agricultural sector.