How Corso’s Horticulture Values Quality and Customer Service

At Corso’s Horticulture, every member of the team cares about quality. Whether their last name is Corso or not, each employee brings hard work and dedication to their job, according to Chad Corso, President of Corso’s Horticulture. With that mindset, the business has built a reputation over its 81 years for excellent customer service and a quality product.

Greenhouse Grower named Corso’s Horticulture as Operation of the Year at the Medal of Excellence reception, held during Cultivate’22 in Columbus, OH.

The leaders at Corso’s don’t just talk the talk, they also walk the walk. Former CEO Gus Corso retired on Jan. 1 and turned over the business to his sons, Chad and Brad. However, Gus still works 40 to 50 hours per week to support the team and offer advice.

Corso’s completed a major step in the succession plan of the third generation owners of Gus, Mickey, John, and Michelle Corso beginning their retirement. Chad and Brad are the current fourth generation owners proudly leading the business into the future, and they are thankful for the past Corso owners. Both generations have been heavily involved in expanding the business to include wholesale, retail, and landscaping over the past several decades.

Gus has been responsible for expanding the business into new markets in the last few decades. Chad’s great grandfather, August Corso Sr., started the business in 1941 by taking fruits and vegetables he grew to local markets. Corso’s wholesale operations began in the 1980s, and now sales revenue from Lowe’s Home Improvement and The Home Depot make up the largest chunk of its revenue. Gus also expanded the business to include a garden center, flower shop, and landscape business.

Corso’s Horticulture focuses on perennials on its 1.4 million square feet of controlled-environment production space and 35 acres of field production in Sandusky, OH, and Castalia, OH. It also participates in contract growing for several large growers. Corso’s has carved a unique niche in the market, Vice President Brad Corso says, because it works in wholesale, retail, and landscaping.

“We live by a saying, ‘You’re either growing or you’re dying,’” he says. “There’s no in between.”

Training New Leaders for Future Success

As the CEO, Chad Corso says he cannot be an expert in every sector of their business. Instead, he surrounds himself with smart employees who will bring their expertise to their job. The team members are 100% invested in the company, he says. Chad values each employee the same, whether they have been at Corso’s for four years or 40 years.

Megan Mahoney, Head Grower at the Castalia, OH location, runs Corso’s international internship program, which started in 2017. It is a partnership with Communicating for Agriculture Exchange Programs (CAEP) and The Ohio Program, an international exchange program under the College of Food, Agricultural, and Environmental Sciences at The Ohio State University.

Corso’s hosts eight interns every year. They take on responsibilities alongside Corso’s growers and assistant growers, eventually leading the interns to take on a grower assistant role.

“We take them on tours to other greenhouses and farms, so they can see other processes and what other local businesses are doing,” Mahoney says. “We try to get them involved in all of our other departments, not just growing.”

Past interns have traveled from Brazil, Colombia, Peru, Kenya, Tanzania, South Africa, Indonesia, the Philippines, Mexico, and Vietnam for this internship at Corso’s.

The internship opens career opportunities for the students. Two past interns are now taking on grower roles at Corso’s. Mahoney says the interns learn about everyday growing practices for the duration of their year-long stay. This includes scouting for pests, applying chemicals, and watering the plants.

Jim Hazelwood has worked at Corso’s for 48 years. He was originally hired as a grower, but learned many other skills along the way, such as plumbing, electrical, and construction work. Many people at Corso’s refer to him as an expert, but Hazelwood does not like that phrase.

“There is no such thing as an expert,” he says. “Just because you don’t know it today, doesn’t mean you can’t know it tomorrow. You are capable of learning something every day. Everyone brags about computers, but the brain is still the best thing. It can store anything if you want it to.”

Hazelwood firmly believes that the next generation of growers can become experts, too. Recently, he helped the younger growers get more involved in the day-to-day operations because they will be at Corso’s when Hazelwood is gone.

CFO Fritz Mueller says Corso’s Horticulture is building new housing for 205 H-2A employees. Corso’s works with Manzana, a farm labor contractor, to hire migrant workers.

FlowVision Speeds Up Truck Loading

Logistics Manager Troy Slauterbeck says Corso’s does not follow the industry standard for trucking and transportation, which he thinks benefits the business. In some cases, drivers sit and wait at the docks for hours while shipments are being loaded and unloaded from the truck. Corso’s notifies their drivers when the trucks are ready for departure.

Slauterbeck says it is critical to pull the orders in a timely fashion so they can be loaded onto the trucks quickly. When he first came to Corso’s in 2017, employees stayed on site to load trucks until 2 a.m. Now they are done by 5 p.m., thanks to FlowVision. FlowVision helped Corso’s implement lean flow practices to maximize efficiency.

For example, Slauterbeck says employees used to pull plants by each truck and build the truck. After working with FlowVision, Corso’s found a more efficient solution. Now, the crew will mass pull the plants for several trucks. In this supermarket setting, the trucks are lined up in the dock. Employees have a “shopping list” and fill each truck with its orders. This allows employees to fill six trucks at a time. Last year, Corso’s filled an average of 38 trucks per day.

Slauterbeck says he has about 45 reliable drivers throughout the year. One driver works for Corso’s and the rest are contracted. The only time he may struggle to find drivers is during the peak season, Slauterbeck says. At that time, he may work with a third party, such as Total Quality Logistics (TQL).

“Usually, their next load is ready, and they just keep going,” he says of the truck drivers’ schedule. “It’s very productive for the drivers’ time.”

Growing Practices Lessen Environmental Impact

Megan Mahoney says Corso’s uses a diverse integrated pest management (IPM) program, including pesticides and biocontrols. In 2016, it implemented More Profitable Sustainability (MPS), software that helps growers reduce their footprint on the environment. The software assigns a color to every chemical used, ranging from white to black. There are no negative points assigned for a white chemical. A green chemical is not as bad for the environment as a black chemical, for example. This software helps growers make decisions about which pesticides to use, she says.

“It’s been a great tool for us to step back and look at our process and chemical usage and make things better for the environment and the health of our employees,” she says.

Rachel Woodruff is the Head Grower at the Corso’s location in Sandusky, OH. She is trialing several biological insects to measure their success rate. In addition, Corso’s has found new processes using technology to be more efficient.

Propagation Manager Lauren Fresch has worked with the Basewell trials from Dümmen Orange, which feature advanced root development without growing media. She found that direct sticking into a pint pot and misting for a couple days saved three weeks and skipped several steps. Also, the AutoStix machine from Visser Horti Systems saves time and labor.

The machine can stick 9,000 plants per hour, when hand-sticking can produce 1,400 plants per hour. If Corso’s receives 60,000 plants, it takes two days with three people using the machine versus three to four days with eight or more people sticking plants, Fresch says.

Mahoney says the growers’ best practice is that they notice problems and resolve them quickly. The employees and management see processes that make them less productive, and they fix them.

No Excuses

There are many practices that Corso’s Horticulture implements daily to help with its success, but Vice President Brad Corso says the most important one is “No excuses.”

The COVID-19 pandemic led to a boom in the green industry. People around the world stayed at home, causing them to beautify their homes with plants. He says 2020 and 2021 were great years for plant sales. As the world settled into its new normal in 2022, plant sales went down.

“We’re seeing how the greenhouse industry has gone down this year on the retail side,” Brad Corso says of market changes. “Our attitude is that we don’t make excuses. That’s a problem, and we solve problems.”

Customers return year after year for the excellent customer service, too. Corso says the best compliment employees can receive is when a customer asks for them by name.

“People come in and ask for Jim Hazelwood when it comes to vegetables; he is the vegetable king. He will tell you what to grow, why, and how to grow it,” Brad Corso says. “It builds confidence in the individuals. They go home and have a successful adventure, then they come back next year and want to try new tomatoes and peppers.”

Former CEO Gus Corso offers a tip for other growers. He says growers must recognize the changes in the industry. If they are not changing with the times, they will fall behind.

“From the time I started until now, it’s a whole different world,” Gus Corso says of the horticulture industry. “Keep in touch and read the industry magazines, you can learn so much.”

Trials to Test Production Success

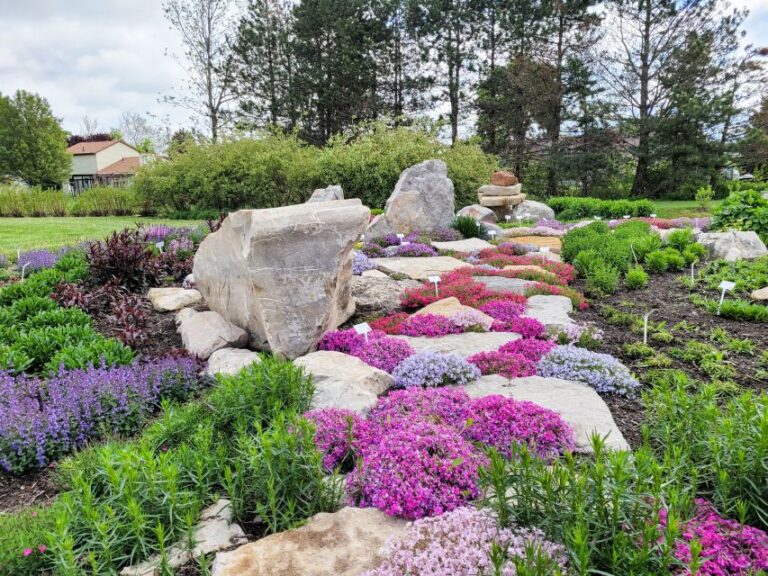

Corso’s trials its plants to weed out crops that will not perform well in its production cycle. All perennials at Corso’s use the same soil, Head Grower Megan Mahoney says, so the trials will show if a plant thrives in that soil. Trialing also allows the growers to see the shape and size of the plants and whether they show disease resistance. The trial manager looks for the longevity of the flowers, flower count, and hardiness. Results of the trials show if the crop is truly a perennial in Corso’s Zone 6 location. Corso’s is trialing 150 varieties this year, according to President Chad Corso.

There are row trials and trial gardens, Mahoney says, noting one greenhouse is dedicated to trials. The trial gardens, one in the sun and one in the shade, also show how the perennials complement each other. The trial gardens are a source of landscape design concepts.

New Housing for H-2A Workers

CFO Fritz Mueller says Corso’s Horticulture is building new housing for 205 H-2A employees. The property to house H-2A employees will be shared with Green Circle Growers. Corso’s works with Manzana, a farm labor contractor, to hire migrant workers. The housing will be completed by Dec. 1, according to President Chad Corso.

“We’re trying to build good housing for those workers. It’s the right thing to do,” Mueller says. “We have a core group of people here every year, growers and managers.”

Our work force is composed of a core group of managers and growers (employees) and that group is supported by H-2A contract workers. We rely on the H-2A group to help plant, grow, pull, and ship the product, Mueller says.

Westrock Congratulates Corso’s Horticulture, the 2022 Operation of the Year

Westrock Congratulates Corso’s Horticulture, the 2022 Operation of the Year

WestRock is deeply dedicated to supporting the grower community. Over 100 years of serving horticulture, we’ve built a long tradition of producing premium packaging and offering superior service to our customers locally, regionally, and globally. From investing in innovation and development, supply chain solutions, and sustainability, to continued expansion of our database of horticultural knowledge and consumer insights, we work hard to be a true partner to our customers by providing the best in tags, labels, point-of-purchase, packaging, and merchandising solutions. We also believe that being a leader in scale and capability comes with responsibility. Today, we are proud to further give back to the community by partnering with Greenhouse Grower to honor and recognize innovation and achievement in the grower industry.