Tips on Optimizing Your Greenhouse Facility Design

The U.S. continues to legalize cannabis in an ad hoc way. As different states enter the market, their legislative priorities vary, which means cannabis businesses must navigate a patchwork of regulations.

Some states, for example, emphasize energy and water conservation, sustainability, and overall resource efficiency, and others make no mention at all. Massachusetts has implemented strict lighting and energy efficiency regulations as well as compliance guidelines.

There are factors to consider when planning new facilities, and for an existing facility, there are operational and efficiency streamlining concerns. For some, there is a notion of “carrots and sticks” from the states and utility providers on cannabis facilities to incentivize sustainability and reduce planet-warming emissions in the face of climate change and increased demand for power.

The Carrots – These are financial incentives from utility companies and/or regulatory bonuses from the state. Massachusetts’ cannabis control commission offers high-performing companies (those exceeding state-mandated energy levels) a kind of credit to use if other aspects of the operation incur a regulatory infringement and present a violation.

Utility companies also have carrots; theirs come as paid incentives to improve energy efficiency. Work with the utility company in your region or state to see what they offer. Each utility will vary, but the rebates are mandated in many markets, as money could be available.

The Sticks – These include license renewal failure and poor energy performance, and the costs associated with that. The operator with the lowest total cost to grow per gram wins, or at least earns the highest return on investment. The inverse is painfully apparent. Washington is among the examples where the dollars per gram is noticeably evident. States such as Massachusetts are now implementing a benchmarking tool at the end of the first year to measure actual energy consumed versus the amount predicted in the design phase.

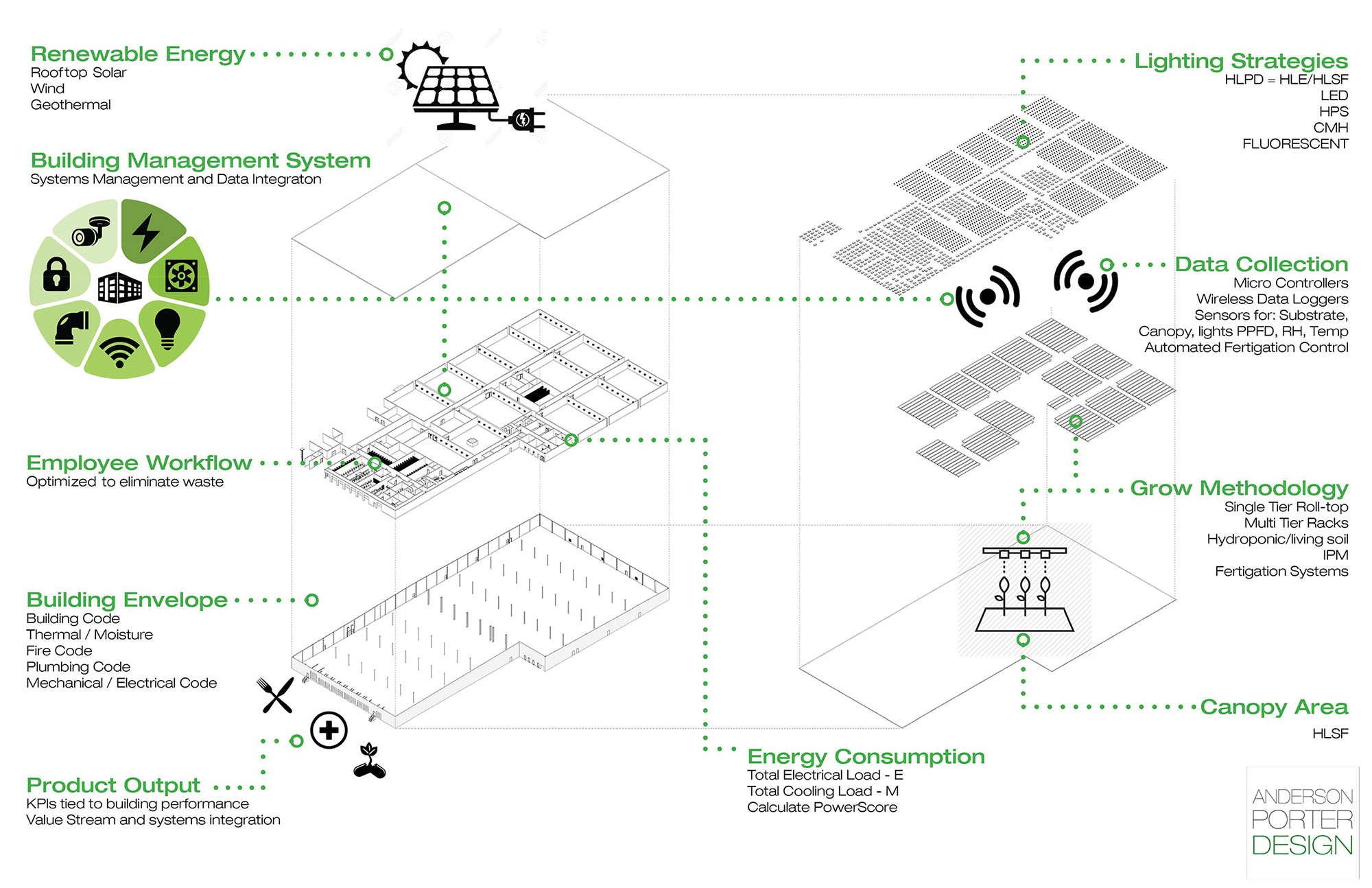

Cambridge, MA-based Anderson Porter Design and its partners assist cannabis operators with facility optimization, design, energy efficiency, increased yields, state regulation, and code compliance. The company has created a comprehensible infographic to better understand the key parts of a cannabis cultivation and manufacturing facility to optimize and drive down the cost of various inputs, such as labor efficiency, utility energy, water, and consumables.

It is imperative to analyze facilities elements and document the entities’ KPIs. Technology can collect data through microsensors, which is then then analyzed and aggregated to identify areas for optimization to increase performance. Data loggers placed in soil, water, plant canopy, atmosphere, and light output can be tied to the building automation system (BAS) or Building Management System (BMS) and tuned depending upon desired targets and results.

Learn more here.