Why Is HVAC so Hard for Indoor Farms?

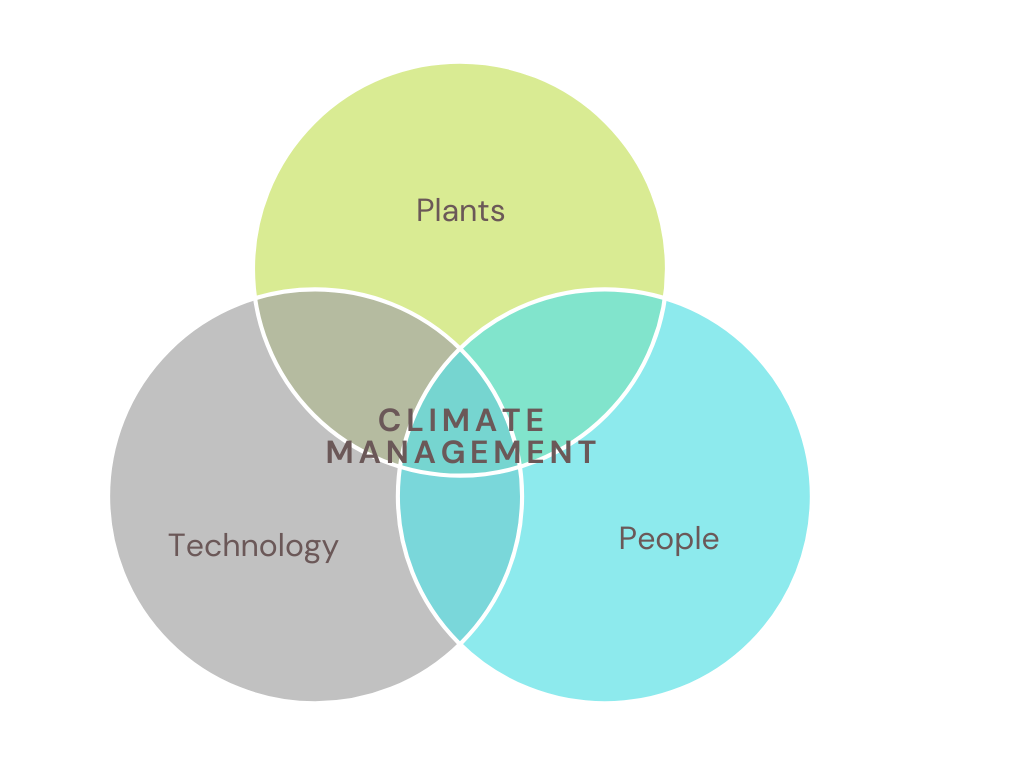

Operators, owners, and facility designers of indoor farms know that climate management is one of the most challenging aspects of growing healthy and productive crops. The big question is, why is it so hard to manage the indoor plant environment? The answer lies at the intersection between plants, technology, and people.

Operators, owners, and facility designers of indoor farms know that climate management is one of the most challenging aspects of growing healthy and productive crops. The big question is, why is it so hard to manage the indoor plant environment? The answer lies at the intersection between plants, technology, and people.

Plants

It’s essential to recognize that the primary occupant is a plant, typically many plants. In an indoor farm, managing humidity and temperature is critical to the health and development of plants. Plants do not go home at night, and they do not go to the office in the morning. Plants interact with interactive building systems.

The plants have changing and fluctuating needs over time, both on a daily basis (photoperiod vs. dark period) and on a weekly or monthly basis (vegetative vs. flowering stages). They are frequently grown in the same spot in the room and can’t get up to change the thermostat (or humidistat) on the wall when it gets too cold or too humid.

All these factors require the engineering of HVAC systems that can monitor and respond to – even predict – the changes in the indoor plant environment.

Technology

Designed for commercial and residential applications, conventional HVAC systems primarily focus on temperature management. Building codes have driven HVAC systems toward energy efficiency to reduce carbon emissions and reduce the demand on power supplies.

Energy-efficient HVAC systems are very good at temperature control. However, less coil depth and greater coil spacing (along with lower refrigerant suction pressure differentials) reduce their capacity to remove moisture. Additionally, most HVAC equipment is designed assuming it does not need to operate at full capacity all day and all year long. But indoor farms never rest and are expected to operate year-round, rain or shine, freezing cold or oppressively humid. As a result, running compressors for cooling and dehumidification under low-ambient conditions can result in failures without implementing the proper safeguards. Further, their constant operation and cycling to meet changing room conditions can wear down equipment quickly, often resulting in frustratingly short equipment lifespans.

When it comes to managing the plant environment, HVAC equipment is generally slow to respond to instantaneous changes, such as turning lights on and off. They are also often controlled by a single sensor that may or may not represent the entire room environment and can’t easily manage multiple climate zones (and microclimates) without multiple units and additional costs.

People

One of the most significant barriers to getting HVAC right for indoor farms is the lack of knowledge and communication among growers, engineers, manufacturers, investors, and other stakeholders. Engineers are not growers, and the majority of them do not understand plants or the environments required to cultivate them. And growers are typically not engineers; they don’t understand thermodynamics, fluid dynamics, or the mechanics of how HVAC systems operate.

Education and communication between all parties will improve climate management of the indoor farm. Engineers and industry professionals who engage with growers to learn more about how the environment affects plant responses and why certain operating strategies are employed, will be in a better position to recommend HVAC equipment that can perform to a desired set of conditions.

Case in point, many manufacturers are actively developing new and modified HVAC equipment to meet the environmental control needs of the indoor farm. Engineers are also asking growers more questions about the lights they’re using, the expected irrigation rates, and operating schedules and room targets in an effort to specify and design better HVAC systems for both temperature and humidity control. In general, HVAC professionals who want to succeed in the controlled-environment agriculture market are asking more questions, seeking guidance from available literature and experienced professionals, and supporting new efforts to conduct research and educate the community.

Growers and investors, too, are becoming more educated and savvy about climate management, either through the hard-knocks of operating a farm with poor climate control, or by attending conferences and classes that focus on research and best practices for horticulture and cultivation. They are learning about the importance of managing vapor pressure deficit (VPD), day and night temperature differentials (DIF), and the daily light integral (DLI) to achieve specific plant responses and meet harvest schedules.

So why is it so difficult for HVAC to manage the indoor farm environment?

For many reasons: Because plants aren’t people, and many people do not understand plants; the indoor plant environment is dynamic and everchanging; the technology hasn’t caught up (yet) to the needs of the plant and grower; and climate management needs and HVAC capabilities (or the lack thereof) aren’t always well-communicated between grower and engineer.

Working together and learning from each other is key to the success of controlled environment agriculture (CEA) and indoor farming. Once we all share a common understanding of how plants respond to their environment, why growers are targeting certain conditions, and what are the capabilities and limitations of HVAC equipment, it will be easier to manage the indoor farm environment and grow healthy and productive plants, anytime and anywhere.