Candidus Is Lighting the Way to Efficient Greenhouse Production

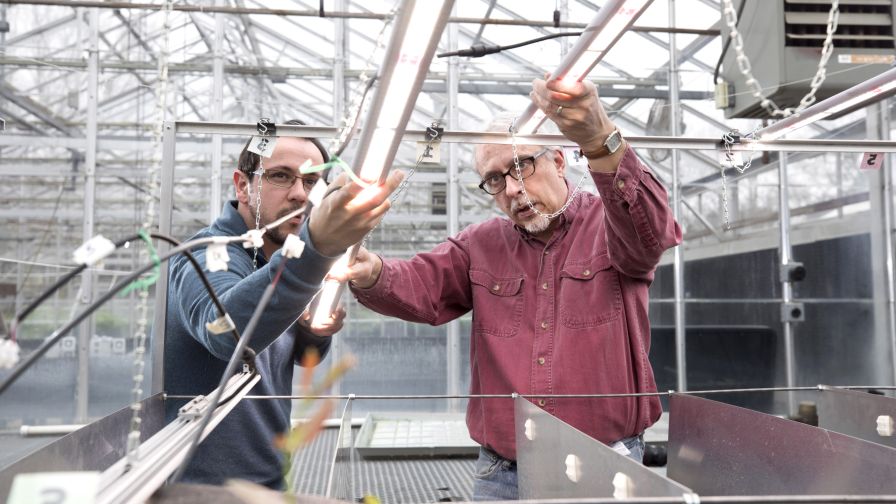

Erico Mattos and Marc van Iersel co-founded Candidus with the goal of helping growers improve their lighting system energy use efficiency and increase operational profitability. Photos: Candidus

A couple years ago, a team of two university lighting researchers and an engineer were looking for a way to help growers improve their lighting system control, reduce energy use, and increase operational profitability. They recognized that while there have been lots of advances in LED lighting technology over the past decade, in the controlled-environment agriculture industry, LED fixtures typically are still used as simple, more efficient replacements for HPS fixtures.

“The unique capabilities of LED fixtures have been largely ignored,” says Marc van Iersel, the Dooley Professor of Horticulture at the University of Georgia. “Yet, there are large benefits associated with dimming LED fixtures intelligently. That was an unmet need that really needed to be addressed.”

Fast forward to 2021, and early adopters are already seeing the fruits of the system that was ultimately developed by van Iersel and his partners, Erico Mattos, a Ph.D. from the University of Georgia, and Dave Hicks, a Georgia Tech engineer with broad experience across several technology sectors.

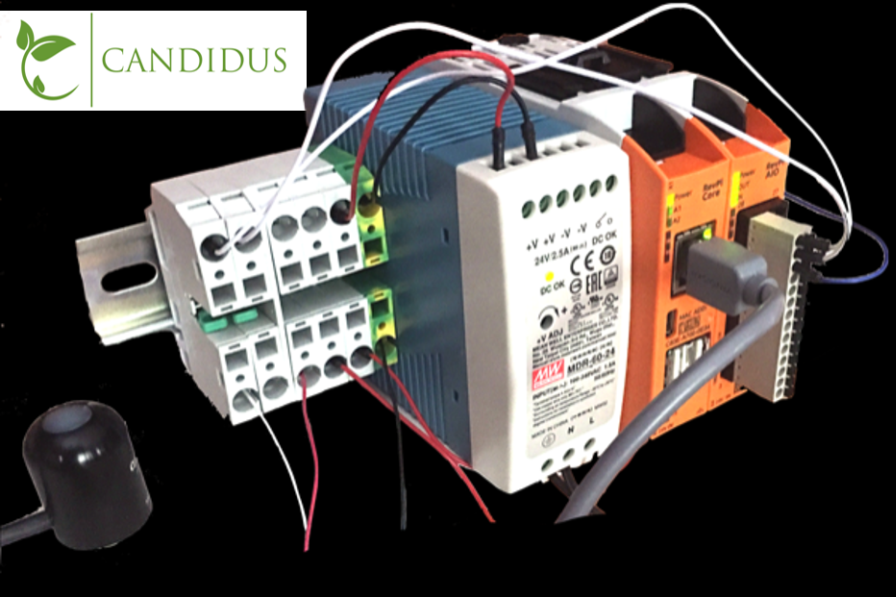

The system, known as Candidus, is designed to provide the required amount of light to meet the crop’s requirements, but no more than that. This approach ensures consistent crop production, while saving energy.

The team’s efforts were recognized this summer, when the Candidus Lighting Controller took home Greenhouse Grower’s Technology of the Year Award during the Medal of Excellence Evening at Cultivate’21.

The most advantageous benefit Candidus provides commercial growers with is the capacity to turn any lighting installation into a dynamic lighting system.

How it Works

The most advantageous benefit the system provides commercial growers is the capacity to turn any lighting installation into a dynamic lighting system.

“We started out by designing a lighting controller that would provide growers with much better control over their daily light integral, regardless of weather conditions,” van Iersel says. “Based on industry feedback, it became clear that other lighting controllers did not provide good control over DLI, resulting in unpredictable crop growth and excess electricity use and cost. We knew we could do better and focused on that.”

Candidus also provides growers with the ability to do night interruption and daylength extension using LED lighting systems at a fraction of full power. It provides monthly reports on the realized energy savings.

“Utilities are very interested in these data and they are now starting to provide rebates to growers who install controllers,” Mattos says. “In the past, utility companies focused on the efficacy of the fixtures, but they now see the value of better control systems, as well. Over the past two months, we were able to secure energy efficiency rebates for our clients in New York and New Hampshire, based on the smart use of light.”

Mattos and van Iersel say Candidus offers a range of benefits, including:

- Energy savings: the controller typically reduces electricity use for lighting by roughly 30%

- More consistent, predictable lighting conditions, which result in more predictable crop growth

- A simple, but powerful, user interface

- Monthly reporting of system performance

- Scalability: the system can be installed in small and large greenhouses and be scaled up over time

- Brand agnostic: Candidus can work with practically all commercially available HPS and LED light fixtures.

Matching the System to the Environment

Based on monthly reports and grower preferences, Candidus provides one year of consulting on how to optimize its use to maximize benefits. There are some trade-offs between energy savings and the best possible control over the DLI.

“This process is extremely important, as commercial greenhouses are very different,” Mattos says. “We have yet to encounter two identical applications.”

Candidus is designed to work on any crop grown in any type of controlled environment.

“Our controller provides the most benefits for greenhouse production, where the variable weather provides challenges,” van Iersel says. “But even for indoor production, our control system is a competitive option, especially since we are willing to integrate with other systems.”

The feedback from early adopters has been positive, perhaps best reflected in the fact that early adopters have scaled up the use of the Candidus controllers in their facilities.

“The Candidus light control system offers enhanced control. It has the ability to track trends, and look at lighting history,” says Paal Elfstrum, CEO of Wheatfield Gardens.

“The Candidus light control system offers enhanced control. It has the ability to track trends, and look at lighting history,” says Paal Elfstrum, CEO of Wheatfield Gardens in North Tonawanda, NY. “The Candidus controller was designed by a grower for growers.”

Alex Traven, General Manager and Head Grower at Peace Tree Farm in Kintnersville, PA, notes Candidus saved about 15% on lighting costs in November.

“But during other months when we didn’t have to light as much, the Candidus controller saved us between 30% to 40% on our energy bill,” Traven says.

What’s Next for Candidus

The current plan, van Iersel says, is continued growth both within the team and on the product side.

“We see great opportunities in being able to respond to variable pricing, which many growers have,” van Iersel says. “The idea of providing light when electricity is relatively cheap is simple. There has been a lot of interest from utility companies in the U.S. and Canada, because it is crucial for them to shift electricity demand away from peak hours. This is a great example of a win/win scenario: lower costs for growers, lower peak demand for utility companies, and new market opportunities for us.”

Candidus has a strong scientific background and was co-founded by plant people.

“Constantly bringing innovations to market, based on growers’ feedback, has hopefully given us credibility among commercial growers,” Mattos says. “With sound solutions and a simple implementation process, we want to stand out.”

Building for Future Growth

While co-founding Candidus, Mattos and van Iersel each had to juggle multiple roles at their respective research institutions (on top of that, Mattos, is also Executive Director of the Greenhouse Lighting and System Engineering [GLASE] program).

“There are long days, but our growth opportunities make the whole process very exciting,” van Iersel says. “As with most startups, we were not able to devote all of our time to the company early on, since we needed to make sure we had a stable paycheck.”

Today, Mattos is in the process of transitioning to Candidus full-time. In addition, Candidus has two full-time engineers, is in the process of hiring a project manager, and is in conversation with a potential CEO.

“With the goal of expanding Candidus operations in 2022, our priority has been on the successful implementation of our commercial systems, scaling manufacturing, and distribution partnerships,” van Iersel says. “Expect big news to be announced in 2022!”