Is It Time for Data Analysis In Your Greenhouse?

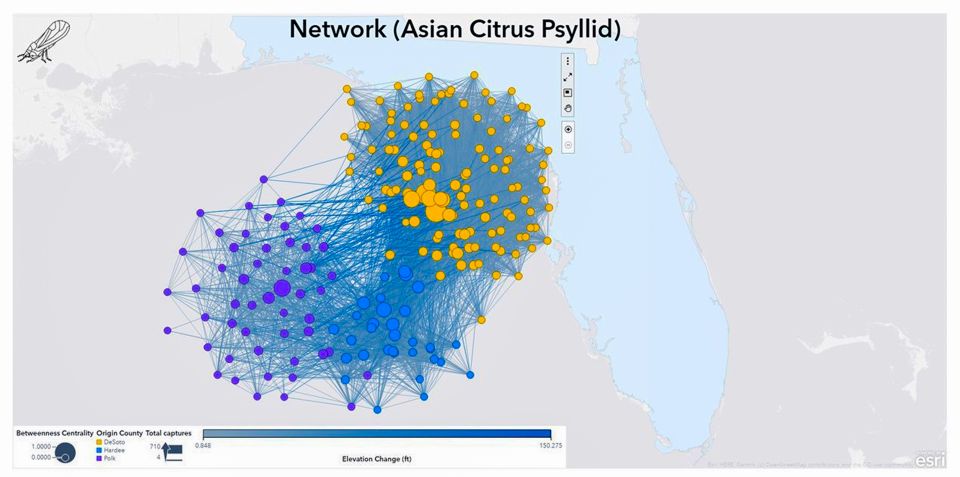

SAS Viya shows a network identifying features of an insect population, an Asian citrus psyllid, that can be used to make decisions on insecticide choice and timing. Photo: Renato Luppi, SAS

Choosing a software system to “help” in your operation can seem daunting. The learning curve can seem awfully steep if you haven’t been keeping up with the times. Words like enterprise resource planning (ERP), data visualization, and dashboard can be enough to make you put the project on the back burner. Maybe some other time when you’re less busy.

But that might be the exact reason to keep exploring the idea. To make you less busy, make your team less busy, and streamline processes. Minimize mistakes. Smooth out all the bumps. While environmental control systems are getting attention lately, greenhouse data analysis extends to the entire business. It integrates supply chains, labor costs, sales figures, even forecasting and planning.

With skilled and experienced growers becoming scarce, data analysis and autonomous systems can be a force multiplier, allowing more space to be managed effectively by the same number of people. These systems can “take care of managing the climate in the greenhouse when you aren’t there,” says Ronald Hoek, CEO of Blue Radix, whether that is to take a bit of time off or to handle other aspects of your business.

Data Analysis Is Critical

Operators commonly track environmental conditions, but what about other data? The business side of your operation is full of data, too. That may be a place where your operation could improve.

“Data systems provide memory,” says John Beauford, President and Chief Technology Officer of Advanced Grower Solutions.

Capturing data about sales, product performance in the market, energy costs, labor costs, culling and waste, inventory, and more provides a record that isn’t subject to vague human recollection.

Data analysis helps with forecasting, planning, and identifying trends. The goal, says John Gottula, Director of Crop Science at SAS, is to “translate know-how into repeatable processes with data analysis, creating business rules to augment decisions.”

A software system for data analysis does more than function like a spreadsheet. It acts as a central repository for data collected across your operation, from the loading dock to the greenhouse floor to accounting. All departments can enter data, and instead of it being on separate departmental spreadsheets (or notepads and stickies), it goes into a single system that can generate reports or sales orders, update inventories, or forecast profitability. For “Lord of the Rings” fans, a good data analysis software system is like the One Ring. One system to rule them all and, in the greenhouse, bind them.

Data collection and analysis also help eliminate the single source of failure common to many operations — that indispensable person without whom the operation would cease to run on a day-to-day basis, whether that’s the manager, grower, or accountant. What would happen if that person became ill, took a different job, or moved to another state?

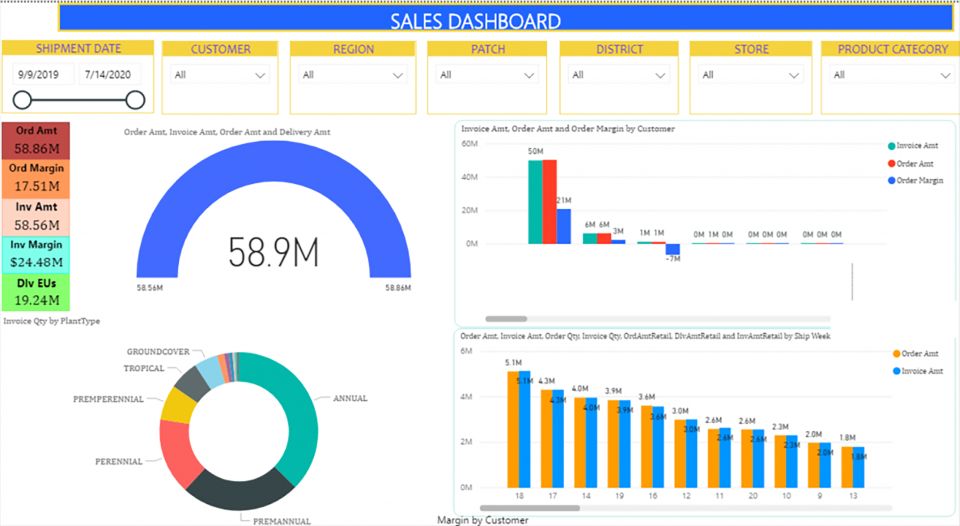

This sample analytic dashboard for sales data is patterned after projects that Advanced Grower Solutions has done with its clients. Photo: Advanced Grower Solutions

Improve Your Bottom Line

While improving system processes, smoothing out the bumps, providing standardized formats, and generating readable reports and figures are excellent reasons to adopt these systems, the bottom line is always of interest. How can spending money on yet another piece of software make money? By helping the operator to identify costs and opportunities for profitability.

Systems like Crop Controller from Blue Radix not only use data from inside your greenhouse but from outside it as well, like energy markets and local weather observation stations. The output can help you forecast your greenhouse climate and even make decisions on climate control within the greenhouse, with your unique crop strategy as its starting point.

“The system ensures, for example, the right temperature, ventilation, and window positions at the right moment, not only for the crops but also related to costs for resources,” explains Hoek. The system goes beyond a dashboard and supplements the skill of an experienced grower.

Beauford says many growers he works with don’t fully understand their profitability. A vague idea based on the price of inputs and the sales price leaves much to be desired.

“Data analysis can help you see where the problems are with profitability. You might already have a hunch, but the analytics prove it,” says Beauford. “Doing the work to do the analysis can give you a different view of your business.”

“Every greenhouse is different,” says Hoek, “even two located next to each other.” Data analysis and improving AI tools can manage at scale more efficiently than humans alone, augmenting their ability to achieve consistency and minimize costs.

Do you really know the accurate and complete cost for your last crop cycle and how that compares to last year? Hundreds of factors interact. Understanding the data can “help you see where there are problems with profitability,” says Beauford.

Other Data Analysis Benefits

The business of growing live plants is unique. Many systems out there are marketed toward all businesses. Find one that’s tailored for yours. “Using a generalized ERP can be difficult for growers,” says Beauford.

Focus on companies that offer data systems tailored for agriculture. Which companies can customize their system for your operation’s size and scope? Also, consider installation locally vs. on the cloud, subscription vs. outright purchase, and how much tech support you need. Is your team tech-savvy? Or do you have talented growers, but you need a person to answer when you call and walk you through an issue?

While it may seem that data analysis is only for big-time growers, Beauford explains that smaller producers may actually benefit more. “It acts like a force multiplier,” he says, automating functions you don’t have people for.