The Science of Shade: Grower Pain Points, and Tools to Help

Choosing the right greenhouse covering or shade starts with understanding your operation’s specific needs — and how each option measures up.

In the first of a three-part series, Greenhouse Grower caught up with coverings and shading systems manufacturers to learn more about the main challenges growers face.

Grower Pain Points

Anicea Kervoelen-Saliba, Area Market Marketer North America for Lumiforte, highlights a few grower pain points:

- Heat stress and crop damage: Without effective shading during high-radiation periods, crops can experience leaf burn, blossom drop, and reduced fruit quality. Heat stress also forces more ventilation, which can dry out plants and increase water and energy use.

- Reduced photosynthesis from stress: Plants exposed to excessive sunlight often close their stomata to prevent water loss, which also reduces photosynthesis and slows growth, even if light is abundant.

- Uneven growth and quality issues: Direct, unfiltered sunlight creates hot spots in some areas and shaded areas in others, leading to inconsistent plant height, fruit size, and overall crop quality.

- Worker discomfort and safety concerns: High inside temperatures from unshaded roofs can make working conditions uncomfortable, slow down labor, and increase safety risks, especially during heat waves.

- Increased energy use: When shading is not applied, growers often rely heavily on ventilation and cooling systems, which raises energy costs and sometimes still fails to fully protect the crop.

Robert Hanifin, Product Specialist for Ridder, says the concerns he hears about include anything from safety to installation.

“Growers may not understand the fire safety measures needed for screens, and what it means for a screen to be flame retardant,” Hanifin says. “They also need to realize that a poor installation can subtract years off the life of screens.”

At Ludvig Svensson, Greenhouse Climate Consultant Paul Arena says the flexibility of screen use year round is a concern.

“The summer heat is immense this year, and growers are looking for better shading and cooling options that can still integrate with wintertime growing and energy savings, Arena says. “Investing in double screen systems are becoming more popular specifically to accommodate growing operations all year long.”

One of the biggest challenges for growers is managing inconsistent or insufficient natural light. Common issues include limited light availability during winter or cloudy days, excessive heat and sun intensity in summer, uneven light distribution across plant canopies, and heavy reliance on supplemental lighting. Add to that the ongoing costs and labor involved in maintaining or replacing degraded coverings, and it’s easy to see why light management remains a persistent concern.

“These issues impact yield, crop quality, and profitability, making it difficult for growers to achieve consistent, optimal results,” says Eric Moody, Vice President of Sales and Marketing at UbiQD, a global leader in quantum dot technology. “Additionally, traditional shading solutions, while mitigating heat stress, often block essential photosynthetically active radiation (PAR), further limiting growth potential.”

Frank Giglia, an industry consultant and General Manager of agriculture nets supplier Signature Supply, puts it one more way: “Growers may have problems articulating what they want. Sometimes they have to sleep on it because they didn’t know they have options.”

Emerging Technology Offers a Range of Solutions

Here’s a closer look at how some of these companies are responding to grower challenges with new innovations.

Ludvig Svensson Harmony 2047 FR; Photo: Ludvig Svensson

Ludvig Svensson Harmony 2047 FR: Climate screens have multiple uses when controlling the greenhouse climate. In the winter, they are used as energy curtains to keep heat inside the greenhouse. In the summer, they are used to reflect intense sunlight to prevent heat buildup in the greenhouse. Using a single climate screen that can accomplish both can be challenging for many growers, especially when you are trying to maximize light in the winter and provided enough shade in the summer. Depending on the types of strips in the screen, growers can manage their greenhouse climate using proper screen management. White plastic screens are the most flexible option currently in the industry. They can retain heat, provide shade, diffuse light, and allow for airflow, conditional to the type of screen you decide to install. Traditionally, aluminum shade screens were the industry standard. Aluminum can retain a lot more heat in the greenhouse as a more insulative material, but it is limited in its efficiency as they normally provide a minimum of 30% shade. Transparent energy screens are much more efficient for winter use as they maximize light transmission and can be closed for longer periods of time. This is where the real energy savings comes in. Each greenhouse is different, so proper screen management will vary depending on the climate, crop, and type of greenhouse.

Ridder Sun Shading Screen, RSS 15 D FR; Photo: Ridder

Ridder Sun Shading Screen, RSS 15 D FR: Greenhouse climate screens (or curtains) help greenhouse growers stabilize and optimize a greenhouse’s climate for crop growth. Screens are specialized knitted or woven textiles installed on (typically motorized) retractable systems above the crop. They serve multiple functions, including light management, temperature regulation, humidity control, and energy conservation.

Climate screens help growers regulate sunlight entering the greenhouse, to achieve their light targets with PAR or radiation, as well as DLI or PARSUM. They can be translucent or reflective, allowing growers to reduce or diffuse light based on plant needs and weather conditions. For example, during peak sunlight, screens can limit excessive solar radiation that can damage the crop, and diffuse or scatter light to allow better light penetration throughout the crop canopy. Conversely, in low-light conditions, such shading screens can be retracted to allow full sunlight to the crop.

Climate screens are also critical for greenhouse temperature regulation, helping to prevent extreme temperature swings during both summer and winter. During hot days, screens reflect or diffuse sunlight, reducing heat buildup and maintaining a cooler environment. This helps minimize energy costs associated with cooling systems. During the winter months, screens are used to trap heated air beneath them, helping to maintain a consistent temperature overnight, and helping the grower to save money on energy costs.

Climate screens also help maintain optimal humidity levels by reducing excessive condensation and preventing humidity spikes that can lead to diseases like mold and powdery mildew. Additionally, screens can assist in managing airflow and ventilation, ensuring fresh air circulation and reducing the risk of plant pathogens and pests from establishing in the crop.

UbiGro Cover; Photo: UbiQD

UbiGro Cover: The UbiGro Cover is an advanced luminescent greenhouse film engineered as a direct replacement for traditional polyethylene greenhouse coverings. The technology leverages proprietary Nobel Prize-recognized quantum dots — semiconductor nanoparticles — to convert portions of sunlight, specifically underutilized ultraviolet (UV) and blue wavelengths, into enhanced orange, red, and far-red light spectra. This optimized spectral shift directly boosts photosynthetic efficiency, enabling plants to grow faster, yield more, and produce higher-quality fruits and flowers.

Unlike conventional greenhouse covers, which only transmit or diffuse sunlight, UbiGro Cover actively converts incoming light without electricity or complex infrastructure. As sunlight passes through, embedded quantum dots fluoresce, emitting photons in the photosynthetically optimal red-orange range (~600 nm). This enhanced spectrum benefits plants significantly and can be beneficial under suboptimal lighting conditions, such as cloudy days, low winter sun angles, or short daylight periods, increasing productivity year-round.

Additionally, UbiGro Cover naturally diffuses light, evenly dispersing it throughout the greenhouse. This reduces harsh shadows and hotspots, providing uniform illumination across the entire plant canopy. Plants at lower levels receive sufficient light, resulting in increased overall growth consistency and yield.

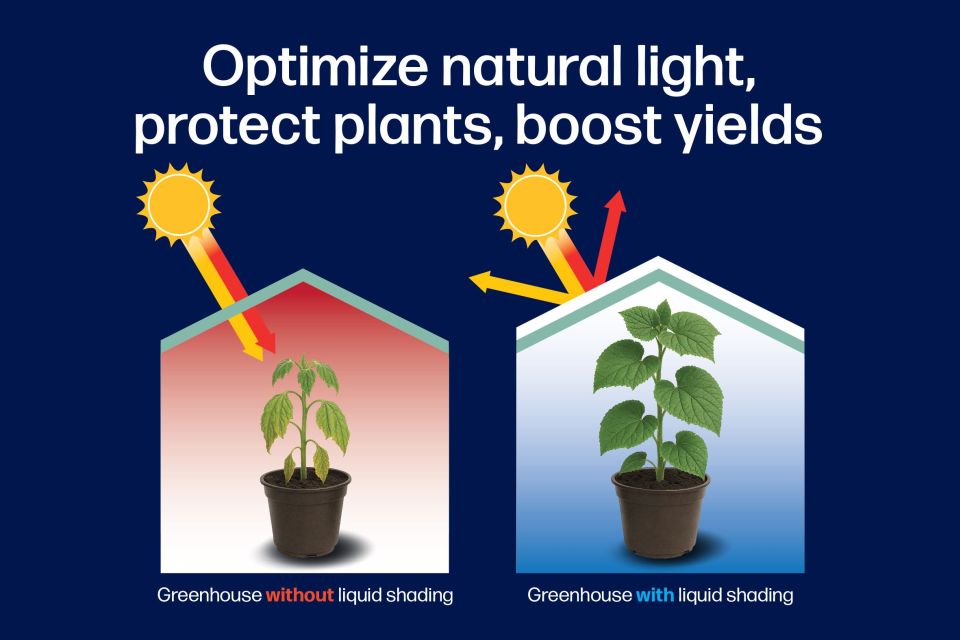

Lumiforte ReduSystem

Lumiforte ReduSystem: ReduSystems coatings are removable, spray-applied layers applied to greenhouse covers to manage sunlight and temperature according to the season. The goal is simple: give crops optimal light conditions year-round while preventing stress from extreme weather. Shading coatings such as ReduSol and ReduHeat are used during high-radiation periods. ReduHeat, for example, blocks infrared heat while allowing photosynthetic light (PAR) to pass through. This reduces crop and greenhouse temperatures while maintaining growth and production potential, ideal for light-loving crops that cannot tolerate excess heat.

Diffuse coatings like ReduFuse and ReduFuse IR scatter sunlight so it spreads evenly across the greenhouse. This eliminates harsh light spots, helps sunlight reach the lower leaves, reduces stress, and often leads to more consistent growth and higher net photosynthesis. Light spectrum coatings such as ReduFlex Blue or ReduCompact adjust the balance of light colors to influence plant development. For example, reducing blue light encourages longer stems in cut roses, while higher blue light levels help bedding plants stay compact and strong. Transmission and reflection products like AntiReflect and PipePaint boost overall light entry and internal reflection, which is especially valuable during low-light periods in autumn and winter.

Cleaning agents (ReduClean) ensure coatings can be safely removed and greenhouse covers kept clean, maintaining maximum light transmission throughout the year. By applying and removing these coatings at the right times, growers can lower heat stress in summer, increase light availability in winter, improve light distribution so all parts of the crop grow evenly, and ultimately optimize yield and quality, all based on proven science and practical field experience.