Using Greenhouse Software to Streamline Production Planning

It can be overwhelming and a bit intimidating when looking at a given week of production and all that goes into getting it done correctly and efficiently. There are many variables involved that need to be managed to avoid chaos and re-work. Here’s a list of just some of the activities and materials to consider during production (you can imagine the variables within these variables, too):

• Plants per pot

• Planting sequence

• Arrival day of incoming live goods

• Rooting hormones

• Greenhouse space/growing environment constraints

• Plant growth regulators

• Chemical or biological controls

• Top dressing

• Tags and labels

• Trimming

• Trays

• Pots

• Soilless media type (stabilized media/special formula)

• Labor hours required

• Machine time/capacity

A few years ago, Pleasant View Gardens made the decision to invest in our greenhouse software and design a workspace to streamline the planning of our production and help organize these activities. We were spending a lot of time putting together Excel documents and relying on word of mouth and hand-written reminders — all of which lead to inconsistencies. While we would always find a way to get the workload accomplished, we felt we could develop a system that would save us time up front, control the chaos, and allow us to measure against our plan each day.

Set Up and Organize

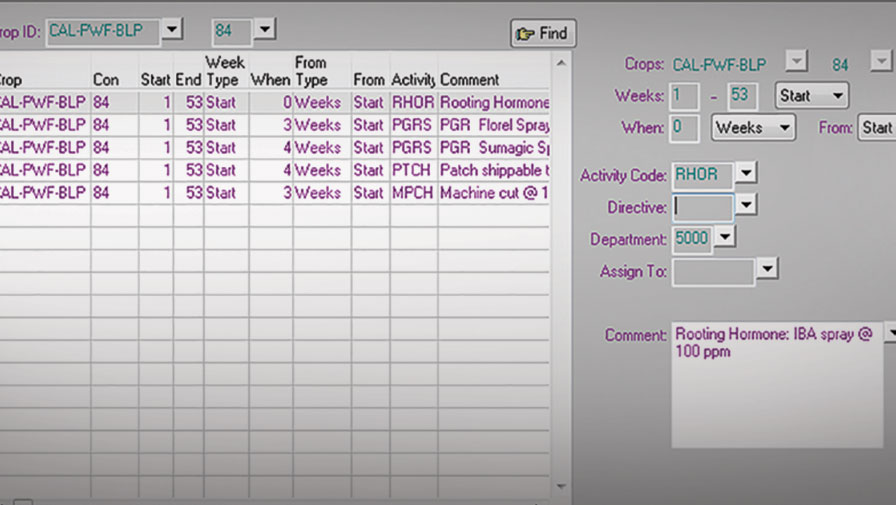

Setting up growing locations, labor, activity, and material requirements before the season assures information flows smoothly and efficiently. Activity requirements take care of the growing recipe, and material requirements yield the necessary hard goods. Reviewing these setups before and after each season with your team is a part of continuous improvement and will gain their buy in.

Plan, Act, and Measure

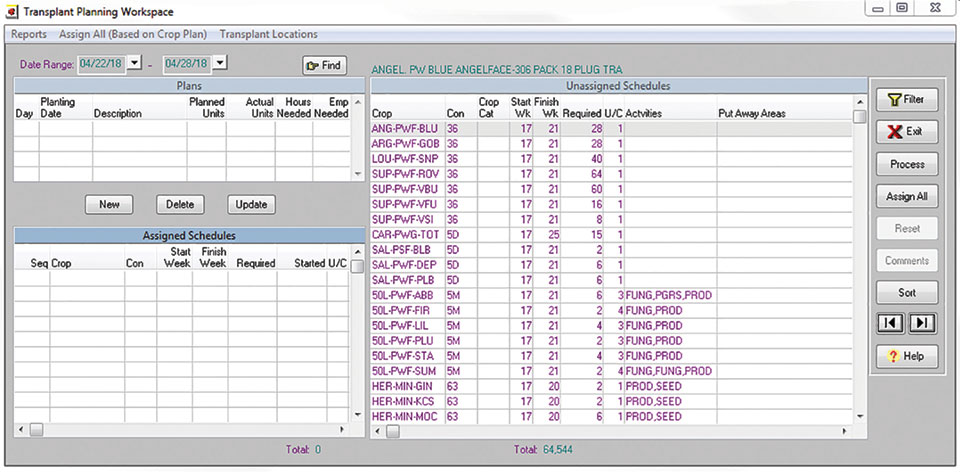

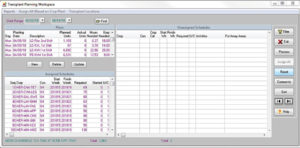

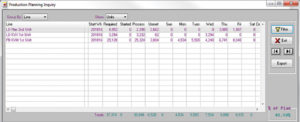

The first release of the software allowed us to set up planting lines, determine the starting location preferences for each product, and account for labor hours. This provides a high-level view of our plan for the week.

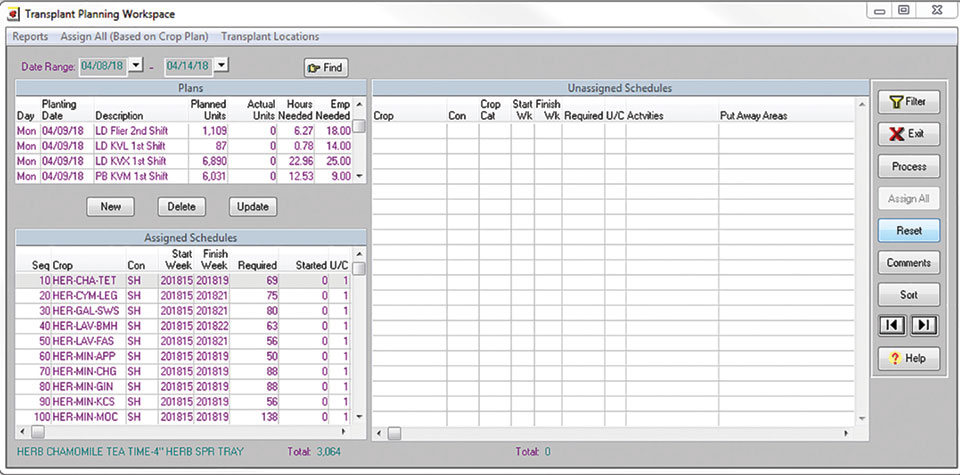

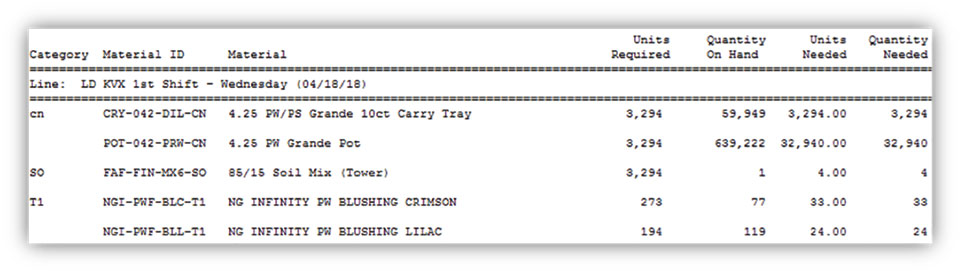

By arranging the workload by facility, day, and shift, we can review the workload and plan accordingly. Labor needs can be modified. Materials required for production can be brought to the proper areas ahead of time.

Subsequent software releases further expanded on these planning efficiencies, driving them to the next step in the process and gathering the starter materials for transplanting. When transplanting rooted liners, the system allows our shipping team to pull in the same fashion as it was set up and organized. A planting line for Monday will receive only the starter materials for that planting line and day.

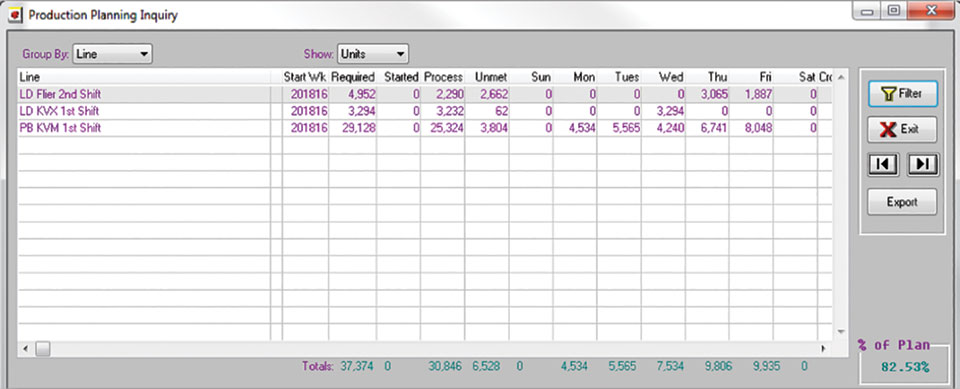

Once everything has been organized and is at the production lines, we’re able to measure the output against the plan by planting line and day. Automatic scanners and handheld scanners auto-feed the data to the inquiry screen. This allows us to adjust our plan to try and stay on track, avoiding costly overtime.

Future Enhancements

Further developments will revolve around the ability to add teams of people to the planning workspace. We’ll be able to assign tasks such as trimming, hanging, and moving as specific lines and see the progress unfold.