Comparing Pay by Scan vs Purchase Order Greenhouse Business Models

A greenhouse grower and a customer can transact business in many ways. When a grower is selling to larger regional or national retail chains, there are two dominant models: purchase order (or PO business) and Pay By Scan, which is also known as vendor managed inventory.

Each of these models has its own processes, data needs, timing, and pros and cons from both the grower’s perspective and the retailer’s perspective.

Purchase Orders

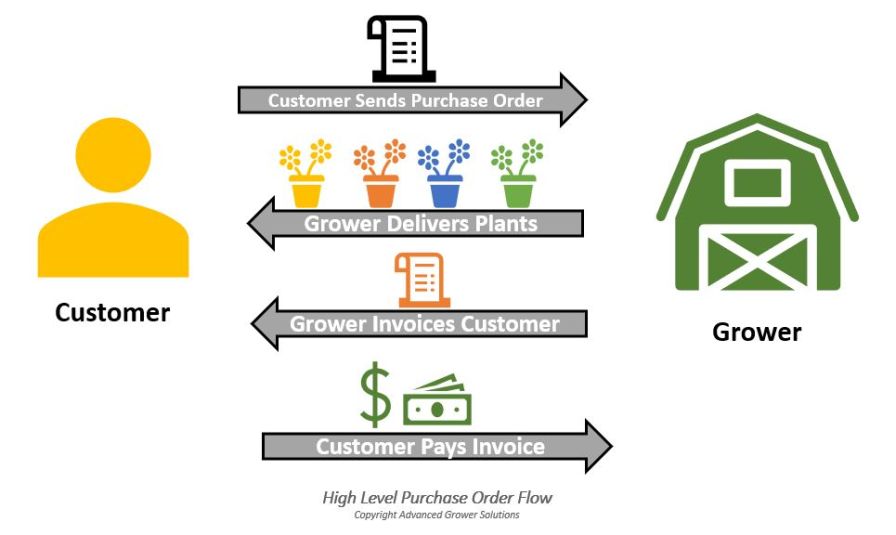

A purchase order is a document (electronic or paper) that indicates the specific items, prices, delivery, and other terms for a purchase of goods between a supplier and a customer.

Purchase orders are the way a customer indicates to a supplier what they want to purchase, prices, and delivery terms. In the grower industry, purchase orders are used for a wide variety of business interactions between growers and their customers.

A grower who uses purchase orders with a customer will typically deliver products in whole or part and invoice their customer based on those deliveries made. The invoices are paid by the customer within the terms of the agreement, say due upon receipt or net 30, etc.

In the purchase order transaction model, the customer usually orders exactly what they want and in the quantities they need.

A variation of standard purchase order flow is the replenishment purchase order flow. Some growers manage the flow of product (quantity) for a customer based on a previously agreed to high-level plan. As the plants mature, the grower’s replenishment team decides, based on plant availability, store sales analytics, and other factors like weather or advertisements, how much product to put into a store in collaboration with a buyer. Typically, a customer will provide the supplier with a document number to use for this transaction. Sometimes that number is referred to as a customer order reference or purchase order number. The number is used by the grower when creating purchase orders on behalf of the customer, so that when the customer’s systems are updated, they can link to that delivery as the PO number that was provided.

A purchase order is created, delivery is done, an invoice is sent and paid as with the normal purchase order flow. In this case, it is the supplier’s replenishment team (usually) that is driving many of the product and quantity decisions on a week-by-week basis.

The main idea of the purchase order is that the grower is paid for the lot shipped under the terms of the agreement, pricing, dates, etc. As such, the purchase order provides some certainty about payments from shipments for the grower.

Pay By Scan

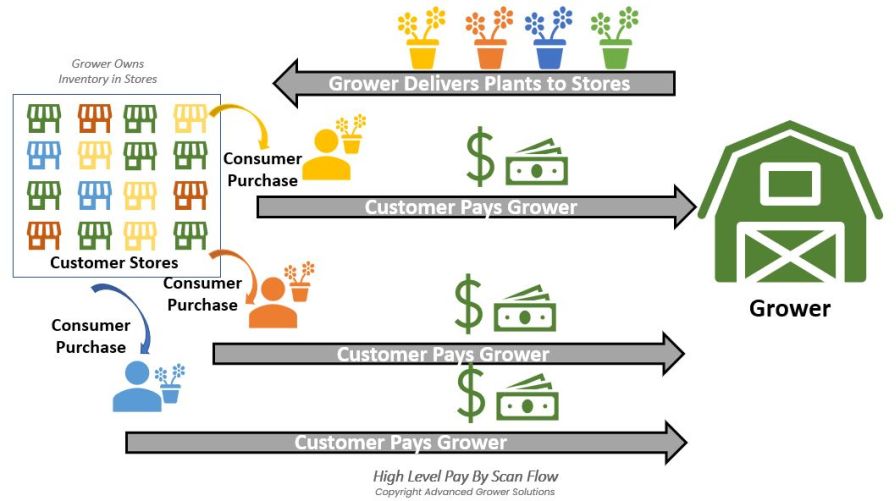

Pay by scan is an alternative arrangement with some retailers whereby the grower (or supplier) stocks the store with items, but the grower does not get paid until items are purchased by the end consumer. The grower still owns the inventory in the store until is it individually purchased.

Under the pay by scan model, the grower must be more acutely aware of the sales patterns in the store to manage product flow effectively.

There are several points of difference in the pay by scan business model.

- The grower doesn’t invoice on delivery.

- The grower gets paid as the plants are purchased by consumers — actual remittance schedules are based on grower terms with the retailer.

- The grower owns the inventory (and risk) at the stores.

- The grower may incur extra costs per sold unit for other services like merchandising.

- The grower needs good visibility and real-time data flows to manage the flow of product in a cost-effective way.

Pay by scan has some additional uncertainties and risks that any grower who chooses to participate in that model needs to weigh.

Systems Support

Pay by Scan and purchase order business process flows have some notable differences. One very important one to the grower is the type of data flows that are required to effectively manage in store inventory levels.

It is important that before a grower enters a new model that their back-end systems support the necessary data, analytics, record types, and transactions of each model. Pay by Scan especially requires a much more retail centric view of product flow than some growers are used to managing.

Success in either model will be punctuated by the ability of the grower’s data systems to manage the necessary data elements effectively.

We have worked with growers who were literally spending hours piecing together reports and key information in support of their model. By adding system support and data flow automations, we have helped growers yield significant improvements and reductions in office labor effort as they grow their business by embarking on new business models.

Bottom Line

Both purchase order and pay by scan are business models employed in our industry. And both have their respective advantages and disadvantages.

For growers to make the best decisions, it is important to have good data to fully understand what the risks of each model are and to make sure that their costing and pricing considers each of the different risk points.