Best Management Practices for Receiving New Plants

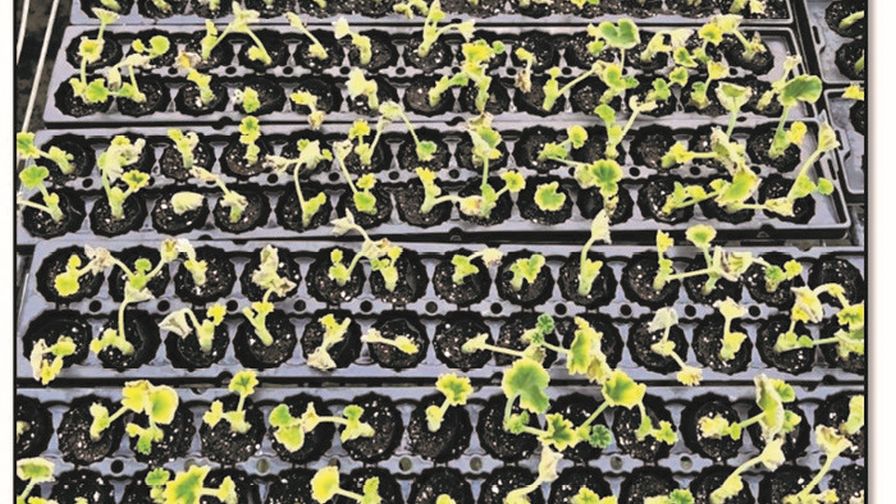

Ethylene damage in geranium unrooted cuttings; Photo: Griffin

The start of many growers’ production season is when their purchased plugs or liners arrive. All too often, the new plants come with their own set of problems that originate from the young plant producers or during transit.

Growers do not have control over the plants before receiving them; however, the best remedy for “purchased-in” plant problems is a proactive approach that starts immediately upon receiving new plant material. In this article, the team at Griffin offers best practices for growers to implement when their new plugs/liners are delivered.

Effective greenhouse management hinges on best management practices like proper sanitation and scouting. Sanitation is a two-step process composed first of using cleaners to remove debris, mineral scale, algae, and biofilm from hard surfaces and irrigation components. Secondly, sanitizers are used such as stabilized peroxygens, like SaniDate 5.0 and ZeroTol 2.0 or longer residual quaternary ammonium products such as KleenGrow.

Scouting can be facilitated with yellow sticky cards or a hand lens. It is especially important to scout incoming plant material so that a clean greenhouse does not become contaminated. Smaller pest populations and early-stage diseases are, of course, easier to manage than large ones, so scout vigilantly to catch infestations and pathogen presence early on.

It’s unrealistic to begin with 100% clean material all the time. However, implementing quarantine procedures can increase this number and ensure a more successful growing season. Upon arrival, always inspect new plant material for signs of insects, disease, and other unusual growth. Even if the plants look clean upon first inspection, it is recommended to quarantine and observe plants in an isolated area, separate from the rest of the production areas. Quarantine areas can be created from plastic sheeting or other physical barriers.

Embracing a proactive quarantine approach is a strategic investment in the long-term well-being of your greenhouse, ensuring resilience and productivity in the face of unforeseen challenges.