MPS Certification Benchmarks Give Growers the Tools to Improve

Applying beneficials | Costa Farms

Editor’s note: This is the second installment of a four-part series on MPS certification and sustainability. Find the first installment here.

MPS has a vast array of offerings for growers. Some may just be looking to benchmark their use of inputs like pesticides, fertilizer, water, and energy and compare it to other growers. Other growers may be looking for MPS certification, whether that’s MPS-ABC or MPS-GAP certification. In some cases, an operation may look at MPS as the first step in a lifelong sustainability journey for the company. No matter what the end goal is, the first step is collecting data.

When a grower chooses to join MPS, the first year is spent collecting data from its production operations. There is an MPS audit after the first year, says MPS Area Manager Maik Mandemaker. After the first audit, they are recurring every three years. There is also an unannounced leaf sample annually.

“We provide a tool so you can spot outliers in your own company. We’ve had a lot of feedback from growers who see unexpected pesticide usage. Measuring is knowing,” says Frank Lammers, MPS Regional Coordinator of North America. “By simply measuring what you’re doing and putting it in writing, it provides growers with insights into their day-to-day process. This is more accessible than people think. Sustainability doesn’t have to be a complicated process.”

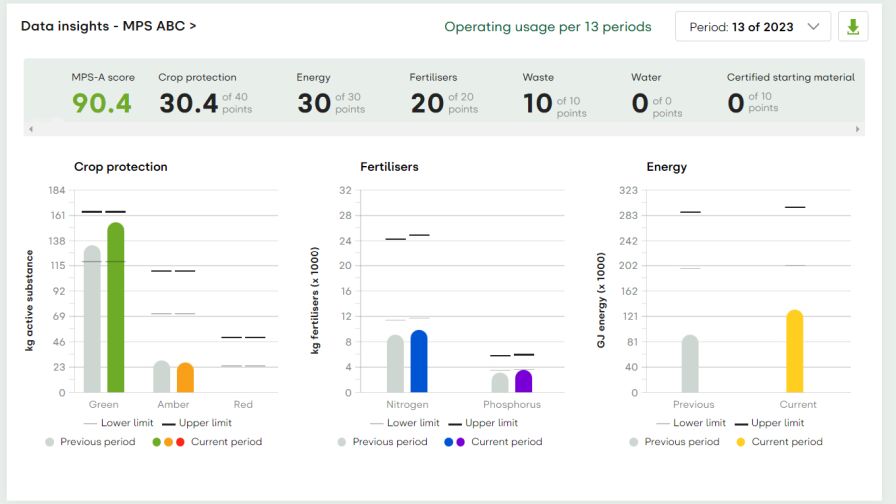

A grower may be MPS certified, but MPS determines what qualification the grower earns based on the data collected. The benchmark group of growers as a whole determines the lower and upper limits within a crop group that subsequently leads to a quarterly qualification. Each grower submits data on its use of crop protection products, energy, fertilizer, and water on a regular basis to earn MPS certification and qualification. After the grower submits the data, MPS compares the data to other growers producing the same crop in the same geographical or climatological area.

The qualification system goes from 0 to 110 points. MPS calculates the grower’s qualification four times per year. Potential qualifications could be a C, B, A, or A+.

When growers log into the MPS portal, they see graphs of their usage of crop protection, fertilizer, and energy. Growers can see a more detailed view of their usage over time. For example, crop protection products with a low environmental impact are colored green in the charts, while the amber and red colored chemicals have a more significant impact. The graphs also indicate the upper limit of the comparison group, and how your data measures up, says Mandemaker.

Growers also see a list of the used crop protection products, including active ingredients and quantities. MPS reviews this usage with growers to point out which products are influencing their qualification most. From there, growers choose how to improve their practices.

Benchmarks Compare Apples to Apples

MPS recognizes that each grower has unique needs based on its geography and the crops that are grown, says Doug Cole, President of D.S. Cole Growers in Loudon, NH.

“Even though we’re all in horticulture, we all do different things. Someone growing perennials may have a fraction of a fuel bill than someone growing an ornamental through the winter,” Cole says. “For people like us — we’re propagators — we’re not running the main house at 60-65°F. We’re running it at 70-72°F. MPS has made different criteria and measurements depending on what you do.”

Cole says similar nuances may come up with crop protection products. His operation may have to spray every crop of liners going out the door for four to six weeks, compared to a grower finishing begonias, for example, which are a 12-week crop.

“The amount of pesticide use for us is higher per calendar day but not necessarily higher per crop cycle. The crop cycle is so much faster,” he says.

By comparing growers’ data based on their location and type of crop grown, MPS ensures that all participants are on a level playing field. Cole says his head grower, Chris Schlegel, has a conservation mindset and spearheaded the MPS initiative. She started out collecting the data, but now guides associate growers through the recordkeeping process. As MPS representatives review the data, they point out potential areas for improvement to the growers.

When growers log into the MPS portal, they see a screen similar to this. The charts show where the grower stands with his or her crop protection, fertilizer, and energy use compared to other growers. | MPS

“They can put things in relative terms,” says Cole. “For fertilizer, they’ll say, ‘You’re OK in general, but your phosphorus level is too high.’ They may suggest that you switch to a fertilizer with a lower phosphorus level. It’s not your total fertilizer use, the individual elements are being watched. It’s good and helpful for us.”

MPS Reports Drive Innovation

Costa Farms holds eight MPS certifications — one for each operating unit. Environmental and Sustainability Manager Maria Giudici says that the company hosts an MPS Summit for its staff from all sites. The head growers and integrated pest management (IPM) managers from each location come together to share ideas, questions, and best practices based on their MPS goals. Growers compare different products available to them, including their cost, effectiveness, and environmental impact.

“At our summit, we look at the correct way to balance our products. Lowering one color (each type of fertilizer and pesticide is color-coded on MPS charts) might make other colors go up a bit. One application of a chemical might resolve any issues, or several applications of another product may be less efficient,” says Giudici. “There has been good knowledge sharing. We set up goals so that our teams come back and continuously improve when it comes to MPS.”

When Costa Farms decided to embark on the journey to MPS certification, Giudici was hired to manage the process, says Senior Director of Environment, Health, and Safety Cesar Martinez. Data collection is managed at each farm, but Giudici oversees the process. She guides Costa Farms in efforts to reduce its environmental footprint and engage in sustainable production practices. Giudici says her team uses MPS reports as a tool to become more sustainable.

“The team is using MPS reports as a tool. We try to figure out which chemical is driving these scores, and start chipping away to lower that chemical use,” says Giudici. “MPS reports categorize the chemicals with colors. Red is the most invasive, then amber and green. White products are biologicals. We consider how to lower the red inputs. Once we have the red inputs under control, then we look at the ambers and figure out how to lower those.”

Giudici says MPS offers an unbiased opinion on how to be more sustainable.

“This is not a complicated process,” she says. “You have a third-party certification saying you’re working within a specific standard. There’s something to be said about that.”

After growers have engaged in the process of data collection, they can begin making changes to their operation. The benefits of these changes will be discussed in the next installment of this series, which will be posted on GreenhouseGrower.com on June 3.