A Fresh Look at Earth-to-Air Heat Transfer

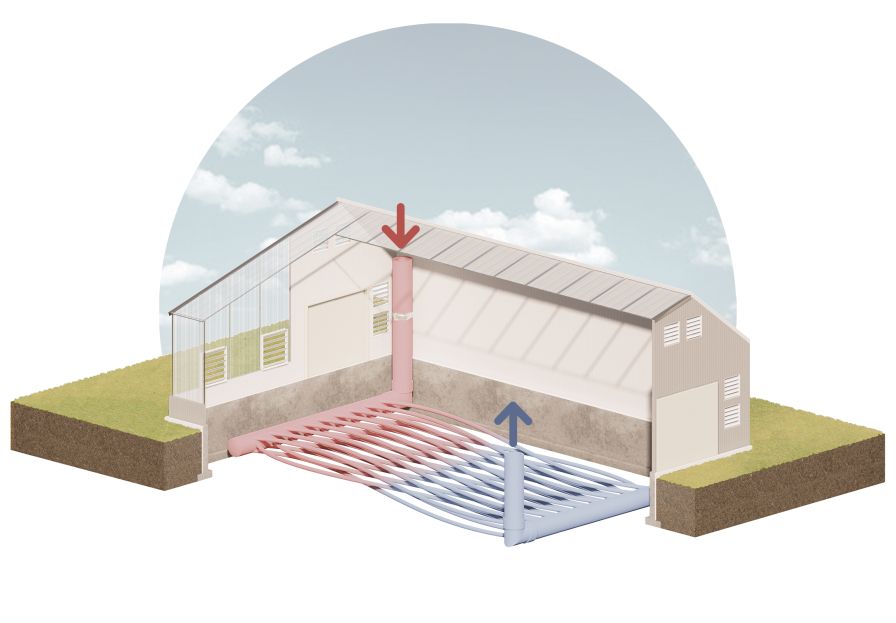

This rendering shows piping below ground for Ceres’ Ground-Air-Heat-Transfer (GAHT) greenhouses, such as Rob Lyle’s greenshaus in Ontario, Canada. Photo: Ceres Greenhouse Solutions

Half an hour west from Parliament Hill, Ottawa, behind a private driveway and out of sight along a pleasant, forested side road at Almonte, Ontario, sits Rob Lyle’s little-but-high-tech, net-zero passive solar greenhouse, known as greenshaus inc. It was growing heads of lettuce, a thousand a week, in hydroponic solutions in frosty January 2023.

An Ottawa-area winter can be harsh and cold; summer can be hot and humid. Last January, outside temps topped out at 20°F and plunged to -5°F; inside, with a bit of propane heat, the lettuce stayed crisp, cool, and quickly growing in healthy, disease-free, pest-free hydroponic nutrients, at around 45°F to 60°F.

A former investment management specialist for large financial institutions, Lyle entered the horticulture business in 2019 with a 2,100-square-foot greenhouse as a prototype for a larger project. The greenhouse was supplied by Ceres Greenhouse Solutions, headquartered in Boulder, CO.

According to Ceres, hundreds of the patented GAHT (Ground-Air-Heat-Transfer) greenhouses have been sold in North and South America and in Europe in the past 10 to 12 years. They range from residential scale to multiple modules measuring 60×100 feet each. GAHT is coupled with other equipment to reduce energy bills.

The geothermal product moves air continuously between the greenhouse and the soil “battery” or “vault” below the floor. Manifolds and fans move the air stream through plastic corrugated irrigation or drainage pipe layered three to four feet underground.

In warm weather, the battery is being warmed by the air flow. In cold weather, the battery is warming air going into the greenhouse, and offsetting costly heating requirements.

Improvements in recent models include new fans for less noise and more energy efficiency, an improved layout for the piping to increase thermal efficiency, and a new Ceres controller (SunSense) that runs the GAHT greenhouse based on input from multiple sensors.

Research Data Predicts Future Performance

University of Guelph associate professor in the School of Engineering, Dr. David Lubitz, wrapped up the first five months of data-gathering on the earth-to-air heat transfer system in 2022.

For the next couple years, Lubitz is looking for opportunities to improve the GAHT system efficiency. Lyle says, “Already, they have come up with several recommendations.”

“We should start to get more general results that will be of interest widely in the next year or so,” says Lubitz. “We have already learned a lot about how Rob Lyles’ greenhouse works and how our model works. This gets interesting in predicting how new greenhouses in other places will perform.”

Lubitz and colleagues installed sensors and other instrumentation to measure the actual heat transfer taking place in the summer. From that data, they built a computer model to simulate energy exchanges with variable conditions.

“For the next phase, we are going to use the model to try other things. We’ll simulate using the GAHT system differently, maybe what (happens) at a deeper depth or if a different sized fan is on it. If the controller comes on in different circumstances, how that will affect the overall energy use,” he says.

“The goal will be to get a better climate in the greenhouse while minimizing the use of energy. This greenhouse has a propane heater. That is necessary sometimes when it gets really cold, but if we optimally use the earth as thermal storage, maybe we can reduce the amount of propane we burn.”

Can You Retrofit for a GAHT Greenhouse?

Growers may wonder, what about a GAHT retrofit for an existing greenhouse? Is that practical?

“Possibly,” Lubitz says. “If you’re doing excavation to put in a foundation or footings, it’s probably less expensive to put in a system like this then, before the greenhouse is already built. However, if you can do inexpensive excavation when the greenhouse is not in use, there’s no reason you couldn’t put one in. Most commercial greenhouses have earth floors. It’s just a matter of excavating trenches and putting the pipe in.”

Going deeper with the pipe to increase heat storage capacity also is a possibility. It could be an option for colder regions of the northern Great Plains.

“Would it cost out? I don’t know,” Lubitz says. “That part we can’t answer at this time. If you’re hiring excavators, the amount of earth moving is very small if you want to go 4 feet deep. It gets much more expensive if you want to be 8 feet deep. It becomes a very major project if you want to be 12 feet deep. One of our interests is the amount of energy you can save. We’re working on putting numbers on that.”

Lubitz sees potential with the earth-to-air systems for year-round greenhouse production at lower than conventional costs. The challenge is in the specific aspects, the set points, for temperatures, humidity, and ventilation to suit the specific greenhouse crops.

As the GAHT system is running now for Rob Lyle, careful measurements show the soil temp and the greenhouse air temp stay “fairly close” throughout the year.

Lubitz says, “We think there are more efficient ways to run it, and that’s one thing we’re looking at. Intentionally having the soil temperature change more would allow us to store more heat and transfer more heat.”

Overall, the system is very mechanically simple and, if set up properly with fans, sensors, and controls, can open other options in ventilation and humidity control

for operators.

“If you run these systems manually, if you don’t have enough ventilation, you can use those fans to move extra air through the greenhouse. In certain conditions, you may be able to use it as a dehumidifier, too. For example, it will really blow the air through, condense some of that moisture out in the ground, and have it come back up with less moisture in it.”

Referring to the university study, a Ceres spokesperson said, “Ceres is glad to have the University of Guelph working on the system and studying it. Their work confirmed what Ceres already implemented in the most recent GAHT projects: reducing airflow and increasing control abilities (with inlet, outlet, and eventually ground temperature sensors).”

In short, from the engineering viewpoint, the greenhouse earth-to-air heat transfer system is simple, seems practical, and probably has potential to be highly efficient after a lot of questions are answered.

As for launching his larger idea, Lyle is hopeful. He’s begun a search for investors.

“With this prototype greenhouse and our hyperlocal distribution mode demonstrating that it works well, we plan to expand to 70,000 square feet. Ceres has completed the estimates for the buildings and systems using GAHT and small propane heaters to minimize the cost of gas and electricity. The facility will cost approximately $15 million to build, grow 12,500 lettuce units per day, and will most likely produce other crops. Best case scenario, 18 months; worst case, 36 months.”