Backup Generators: Easy Sleep Made Easy

I’ve done my share of risky things. I’ve been into extreme sports my whole life, jumped off high cliffs just for fun and driven way too fast for my own good (or the good of my insurance premiums). I’ve even dated a Sicilian girl with two large brothers before. These are just a few of the risks I’m willing to go on the record about — there’s more, believe me (and probably a lot more than I can recall!) One thing I’ve never willingly risked is my livelihood. Like many of you, I’ve been blessed to work in a field I am passionate about. Therefore, I make sure to keep my priorities straight and have backup plans in place in case something unforseen happens.

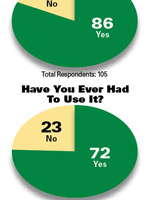

Which brings us to the topic of generators. As the chart shows, a recent survey conducted in our Benchrunner e-newsletter showed that about one-fifth of growers have no backup power generation system in place, much less one adequately-sized and properly maintained. In these days of rolling blackouts in the summer and winter ice storms, outages affecting crucial greenhouse equipment can happen for many different reasons and in any season. Your heaters and boilers need electricity. Solenoid valves control the entry of fuel, the safety controls, thermostats, intake air fans and more all run on electric power. Your environmental controls, no matter how simple, need “juice” to run the exhaust fans that vent hot air and keep the plants happy. And speaking of “juice,” what about irrigation pumps? One Southern grower who replied to our survey said of his unit, “The generator supplied power to run our well, greenhouse and the tissue culture lab and offices after two hurricanes knocked out power.”

Skydiving Sans Parachute

Sound like fun to you? “Any grower going without a back-up generator is basically working without protection,” explains Peter Stuyt, president of Carpinteria, Calif.-based Total Energy Group. “A grower with 14 acres told me once that a single outage cost him about $25,000 in crop damage, so he looked at his $80,000 investment as having not a three-year but a ‘three-start ROI.'” Keep in mind that $80,000 buys a lot of bells and whistles (as well as the generator to power them) and for much less, you can get a more basic system that still fits your particular needs.

Growers from our survey had no brand preference, choosing Caterpillar, Kato, Sears, Generac, Kohler, Onan and other makes and models of various sizes to keep their nighttime sleep easy. If your budget is low, think about shopping around for used equipment — like any motor, if it has been properly maintained it will last a long time. Don’t cut too many corners, though, as the last thing you want is to need a backup system for your backup.

Peak Demand & Co-Generation

One final consideration is that these generators can actually help pay for themselves in a few key ways. Before deciding on the size of your generator, check with your local utility companies. Many allow growers who produce power to sell excess back to the grid, which might bring growers initially looking to invest in a generator into the realm of co-generation. Many utilities have special agreements in which they charge lower rates if a grower with a good backup system allows himself to be cut off from the grid in case of peak demand emergencies. Depending on where you live, your state may have incentive programs for installment of these backup systems. Finally, check with your insurance company, as having an adequate backup generator system might save on liability or crop insurance.

“If someone is trying to ensure that life goes on in a power outage, that’s totally different than trying to isolate from the grid, whether for 8,000 hours per year or as a way to reduce usage and cost during peak demand times,” says Mike Devine, gas product marketing manager for Caterpillar. A grower from our survey reported, “We’re part of an energy reduction group to reduce grid demand, as well as when we have power interruptions.” With energy prices high and unstable, grid isolation and co-generation (already used extensively in Holland and Canada) are more economically attractive options here.

Go to our Grower Tools page (www.greenhousegrower.com/grower_tools) for an article from Kato Engineering about prolonging the life of your generator, and sign up for our Benchrunner e-newsletter at www.greenhousegrower.com/benchrunner.