Prevent Greenhouse Fires With Thermal Imaging

In 2009, Hortica Insurance & Employee Benefits determined 48 percent of its property claims payments were fire-related. When trying to find a solution to reduce customer fire claims, the company began testing a thermographic imaging program. Hortica found that this program may have successfully reduced fire-related claims to 43 percent, ultimately creating a savings for its policyholders.

Thermography has since become a service that Hortica provides to all of its customers. This service involves a visit from a Hortica thermographer to identify anomalies that may contribute to or result in costly damage to equipment or a disruption in business operations. Common problems identified by thermal imaging include overloaded, worn-out and broken circuit breakers, overheated circulating fans, failing fuses and contacts, loose connections and energy loss.

Identifying Problems

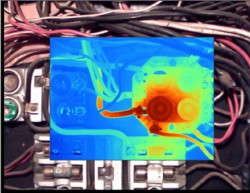

Thermal imagers identify potential problems quickly without shutting down equipment or an operating component, which is a major benefit to business owners. This is possible because the thermal imagers operate on infrared principles. Electrical optical devices are used to detect and measure radiation, and the radiation is then correlated to the surface temperature. A thermal exception often appears using the thermal imager even when a visible inspection reveals very little, if anything. Thermal imagers are a cost-savings tool for maintenance and inspection of electrical systems, troubleshooting mechanical systems and analyzing building envelopes.

Thermal imaging has long been used for various applications related to building envelopes. Building diagnostic applications include building insulation inspections for energy, air leakage and moisture detection. While air itself cannot be seen, its temperature patterns on building surfaces often have characteristic thermal patterns.

Troubleshooting Equipment

Thermal signatures are snapshots of the heat being given off from an object at a single point in time. Comparing the thermal signature of a normal operating piece of equipment to one being evaluated for abnormal conditions offers an excellent method of troubleshooting. For example, excessive heat produced by an electrical system is a sign of impending trouble.

High temperatures indicate excessive electrical resistance, failing components or other common problems in electric equipment that can lead to expensive or even catastrophic failures. Motors are thermally inspected because they are very susceptible to heat-related failure. It is valuable to look at motors with thermal imagery compared with similar operating motors under similar conditions. For example, thermal imagery can help identify horizontal airflow fan motors that are running hot or a belt and pulley out of alignment.

A requirement for detecting conditions that are possible problems is access to operating and loaded equipment with the thermal imager. While not all equipment can be running all the time, it is possible to maximize the number of pieces of scan-ready equipment if the visit is made during a time when the facility is at or near full operation. Electrical components must be energized and loaded. A full load at a normal operating level is preferred and should be loaded to at least 40 percent. Low loads may not show problems.

Electrical cabinets must be accessed with the panels opened to gain a clear line of sight between the infrared camera and the points of interest. All opening and closing of equipment must be conducted by site personnel. These individuals are properly trained and experienced with working around live electrical circuits and are permitted to do so.

By using thermography, Hortica creates bottom-line cost savings for its policyholders. Other benefits include reduced opportunities for fires, assistance with preventive maintenance to avoid business interruption and decreased energy costs overall.