Dümmen Orange Implementing Consistent Standards On All Offshore Cuttings Farms

Owning and operating several locations can be a challenge in maintaining consistent quality and cleanliness across the board. This is true of both breeders and growers. But those who do it right have invested in technology and practices that ensure that plant quality matches, no matter where their plants are shipped from.

That’s the goal for Dümmen Orange. Now the world’s largest producer of unrooted cuttings, the company has a combined 150 hectares or 370 acres of production space worldwide, dedicated to cuttings production. Recent acquisitions of product portfolios, both this year and in the past few, has raised the company’s cuttings production expectation to more than 1.4 billion, including 350 million in North America. It has farms all over the world (see the 2015 Top Cuttings Producers ranking to see where), and produces cuttings for its own genetics, as well as collaborating with more than 30 third-party breeders across all six of its product categories.

With all of these numbers under its responsibility, and past issues with disease outbreaks that it never wants to see happen again, Dümmen Orange is aggressively working to put safeguards in place, and to upgrade its phytosanitary standards and profile to a position of leadership.

“Our goal is to raise the bar, not just for ourselves, but for the industry,” says Operations Director Kate Santos. “We want to be at the forefront of offering clean product to our customers, and that can only be achieved by adhering to our fundamental approach to sanitation in everything we do – starting clean and staying clean. Every process at each of our farms revolves around this.”

[blackoutgallery id=”76004″]

Fine-Tuning Standards

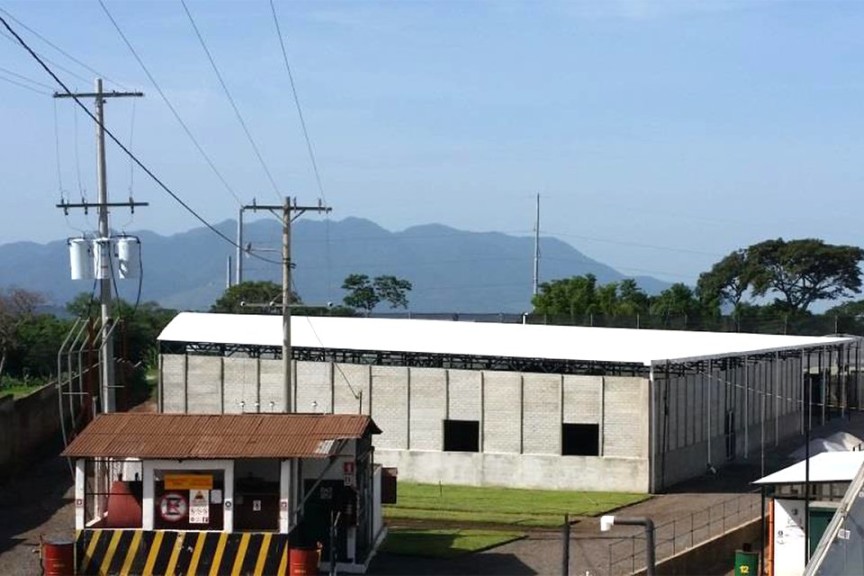

Two years ago, Dümmen Orange completely redefined its Solanaceous (Calibrachoa, Petunia, etc.) production protocols two years ago, after it had problems with Tomato Mosaic Virus at its El Salvador farm, Las Mercedes. New measures included 3.6 hectares of new greenhouses that were segregated into isolated compartments with concrete floors, separate tools, clothing and dedicated staff for Solanaceous crops only. Since then, the same caliber of protocols has been applied to all of its farms.

“(It has) incited a complete assessment and refinement of all of our sanitation standards across all crop classes, from the start of breeding through to unrooted supply to our grower customers,” Santos says.

Recently, Dümmen Orange hired two key team members – Johan Trouw, managing director of the supply chain and Jaco Van Straten, phytosanitary manager.

“Their leadership will continue to educate our team, drive continued improvement in our supply chain phytosanitary processes and protocols, and ensure our teams maintain a start clean, stay clean approach,” Santos says.

The two managers will be part of a phytosanitation network being built across all production facilities, including a quality assurance manager for every farms, who will ensure each farm is in compliance with all standards, as well as ensuring training is up to date and all employees are consistently improving. For example, scouting staffs will be trained regularly on the most current symptomology of both abiotic and biotic factors that could affect crops.

Testing protocol has been elevated and standardized across all production farms and within crops that are susceptible to high-risk pathogens. Farms in Guatemala and El Salvador now have on-site testing laboratories on site, where trained phytopathologists can quickly test and assess plant facilities.

At the facility level, upgrades across all production farms have been elevated to meet the standards set for the operation globally, including all crops being grown in covered, closed and controlled greenhouses with restricted access, footbaths at every entrance and standardized washing and disinfection protocols, Santos says. All employees have required uniforms supplied on site, and no street clothes are allowed beyond defined red areas once on location.

Finally, the organization is ready should anything happen, with an emergency response plan.

“While our desire is never to have to use them, we are prepared,” Santos says. “Emergency response trees were defined should a problem arise that outlines immediate notification communications, stopping shipments, quarantine and disposals. Having these pre-emptively defined ensures that our response time is as fast as possible to minimize spread and impact.”

Developing Opportunities And Executing Promised Quality

Dümmen Orange recently completed MPS certification at its Las Mercedes, El Salvador farm.

The global organization has earned MPS ABC and MPS GAP at several of its facilities worldwide. It has achieved MPS Socially Qualified at its Uganda, El Salvador and Ethiopia farms, and is certified for Fair Trade in Ethiopia.

Heading into 2016, Dümmen Orange is focusing on opportunities for growth and execution, Santos says. With all of the recent changes, from working toward streamlining its product portfolio under one rebranded name, buying the Florexpo portfolio and upgrading the Antigua Flowers facility to take on this supply, and upgrading facilities, personnel and standards at farms worldwide, the company has a full agenda.

“Our opportunity for 2016 is to focus on our production supply and our customers, to tailor our service to their needs and ensure we supply a quality product on time,” Santos says.