Why Biofilm Can Threaten Your Greenhouse Irrigation System

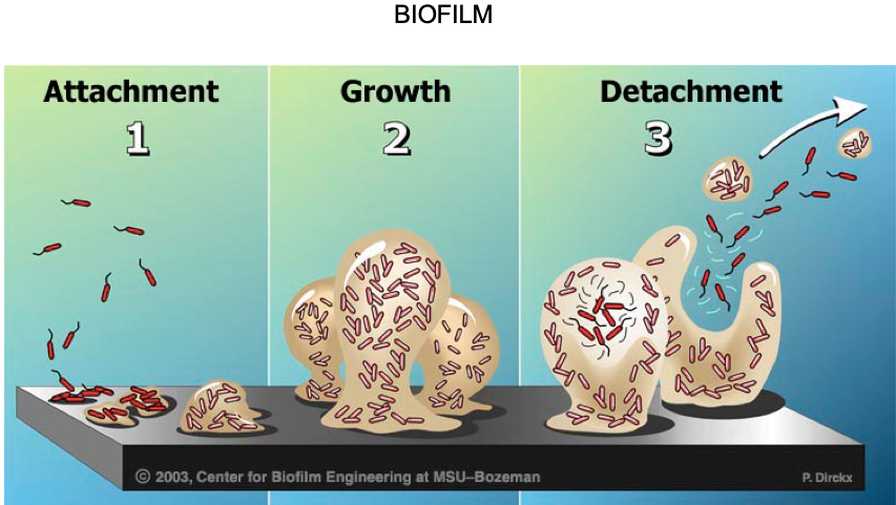

The three stages of biofilm

Note: This article is part of a series in which Greenhouse Grower and L.L. Klink Greenhouse Solutions (a national sales and service greenhouse provider) are partnering to provide you with information on how to most efficiently manage your greenhouse. Check out the other articles in the series here.

If your greenhouse has an irrigation system, you probably have biofilm in it, and it is probably causing problems.

Greenhouses and nurseries are particularly vulnerable to biofilm, a complex structure adhering to surfaces that are regularly in contact with water, consisting of colonies of bacteria that secrete a protective coating in which they are encased.

Light is not necessary to create biofilm. It is easily created in nutrient-rich environments such as a greenhouse irrigation system, where ample supply of fertilizer-injected water assures an ample food supply to the bacteria.

Biofilm is created very quickly and needs to be continuously treated. If not treated, your irrigation system becomes a distribution point for detached biofilm clogging irrigation lines and emitters, which leads to extra labor, crop shrink, and irrigation equipment costs.

Here is a quick overview of the stages of biofilm, its attraction to horticulture, and the most effective treatments.

Stages of Biofilm

- Pioneering Attachment: Bacteria begin to attach themselves to the surface of piping and tubing and secrete a extracellular polymeric substance (EPS) that provides a protective matrix and a home for bacterial colonies.

- Growth: Once a protective matrix is formed, the cells will split and recruit other cells to attach to the hospitable environment.

- Maturing: Fully functioning biofilm, in which a three-dimensional structure is formed. Cells are packed in clusters with channels between them to transport water.

- Detachment: Breaking off and distribution of cells that are transported via water, which creates additional bacteria and biofilm downstream, posing a direct risk to the plants.

Biofilm’s Attraction to Horticulture

Biofilm thrives in greenhouse and nursery operations because the majority of greenhouse and nursery operations utilize untreated surface or well water. Both environments have nutrient-rich water, which enables the bacteria to thrive in a high temperature environment with several small pipes that are usually light permeable. Greenhouse and nursery operations also have several exposed outlets (e.g., hose ends, nozzles, etc.) which enable the transfer onto other surfaces where the formation of biofilm can begin.

Biofilm Treatment

Several methods to treat biofilm (heat pasteurization, UV light, chlorine, hydrogen peroxide) have been unsuccessfully tried. However, treatment programs that have been proven effective for treatment of biofilm include:

- Continuous ozone treatment: Ozone treatment removes bacterial microorganisms from the water, but it also halts the accumulation of biofilm in your pipes and water system, which greatly improves the quality of your water. Ozone also penetrates mature biofilm, removing the matrix. The operational cost is only a small use of electricity, but the up-front price tag for the system can be a deterrent for some operators.

- Continuous chlorine dioxide injection: A much more affordable up front solution, chlorine dioxide is able to penetrate the mature biofilm, and will over time destroy the biofilm matrix. It is important to review the chlorine dioxide product to make sure the formulation enables a controlled release, as some product can be toxic to plants.

- Shock treatments with acidic acid (50/50 water and vinegar): This periodic approach will work if the first two mentioned above are not available or affordable. Although good for periodic treatment to treat or temporarily remove biofilm, this approach would not be recommended for continuous treatment.

The impact of biofilm continues to cost nurseries and greenhouse operators millions of dollars per year in added labor, crop loss, equipment, and added chemical costs. Although limited, the solutions on the market can assist operators in properly treating/eliminating biofilm if placed within a regular treatment program. Greenhouse supply companies like Midwest Greenhouse Supply should be able to assist in providing guidance on developing a biofilm treatment program that aligns with your operational and budgetary requirements.